Optical measuring method of vibration and optical measuring system

A measurement and optical technology, applied in the direction of measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problem of difficulty in setting up measuring equipment, and achieve the effect of being easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

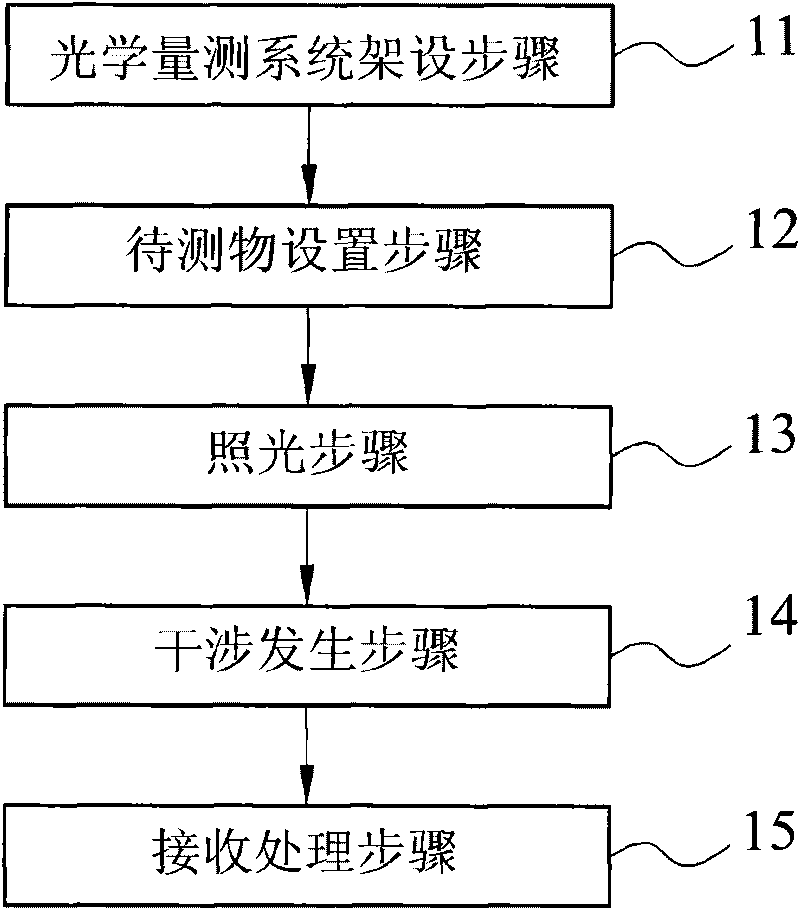

[0026] refer to figure 1 , figure 2 , a preferred embodiment of the vibration optical measurement method of the present invention, comprising five steps of the optical measurement system erection step 11, the object to be measured setting step 12, the lighting step 13, the interference generation step 14, and the receiving processing step 15 , and the vibration condition of the object under test 100 can be measured quickly and accurately without touching the object under test 100 .

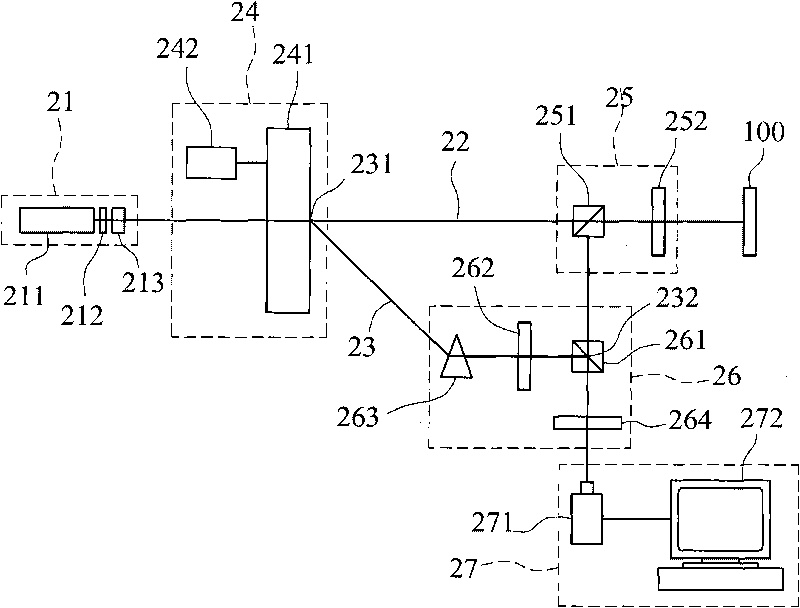

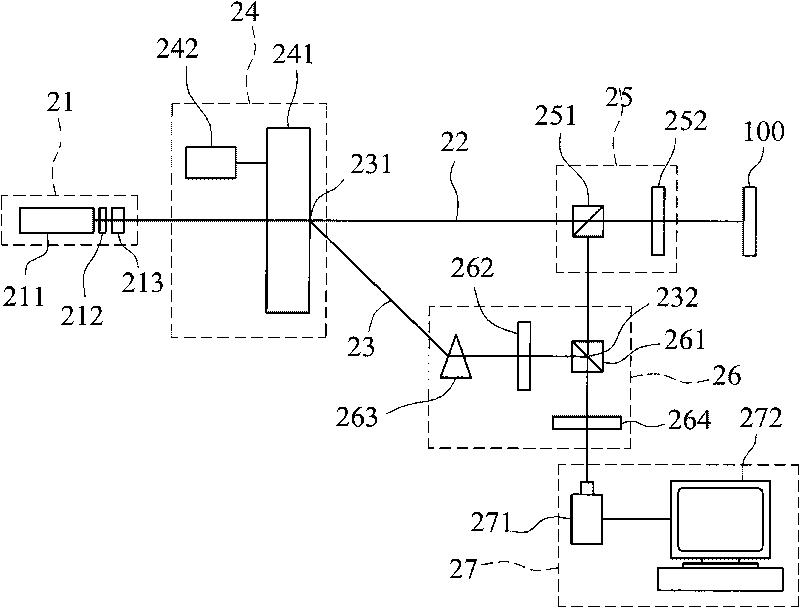

[0027] Such as figure 2 As shown, the optical measurement system erection step 11 is to set up a group of optical measurement systems 2 .

[0028] The optical measurement system 2 includes a light source 21, a first optical path 22, a second optical path 23, a first optical assembly 24, a second optical assembly 25, a third optical assembly 26, and a light receiving Processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com