Detecting device for laser noise-signal ratio

A detection device and a technology of signal-to-noise ratio, which is applied in the direction of instruments, etc., can solve the problems of low signal-to-noise ratio, poor accuracy, powerlessness of signal-to-noise ratio of a single laser pulse, etc., and achieve the effect of convenient use and intuitive measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

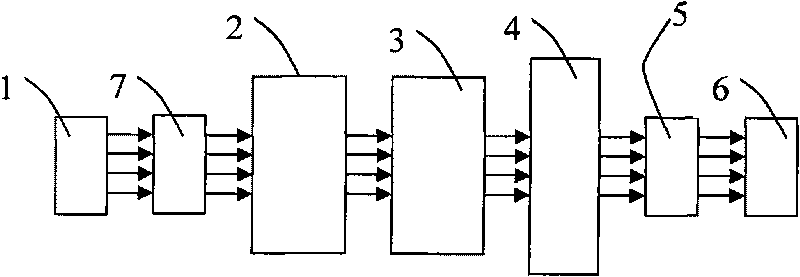

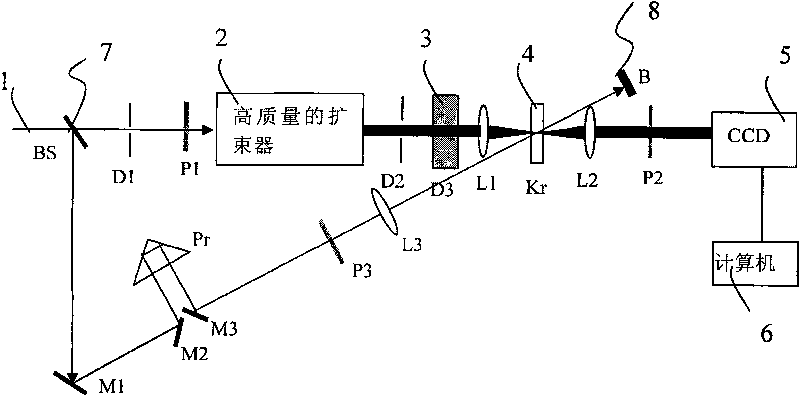

[0021] see figure 1 , the present invention provides a laser signal-to-noise ratio detection device, the laser signal-to-noise ratio detection device includes a light source 1, a beam splitter 7, a beam expander 2, a single-pulse optical retarder 3, an optical Kerr medium 4 and a detector 5; the beam splitter 7 is arranged on the output optical path of the light source 1, and divides the light source 1 into shutter light and signal light; the beam expander 2 is arranged on the output optical path of the signal light separated by the beam splitter 7; single pulse The optical retarder 3 is arranged on the output optical path of the beam expander 2; the optical Kerr medium 4 is arranged on the output optical path of the single pulse optical retarder 3 and the output optical path of the shutter light separated by the beam splitter 7 intersects in space position; the detector 5 is connected to the optical Kerr medium 4 .

[0022] The laser signal-to-noise ratio detection device al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com