Assembly test table of pivoting support of windmill generator

A technology for wind turbines and slewing bearings, which is used in mechanical clearance measurement, force/torque/power measuring instruments, measuring devices, etc., can solve the problems of fast hoisting, affecting measurement accuracy, and low efficiency, and achieves a high degree of automation. , the effect of low labor intensity and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

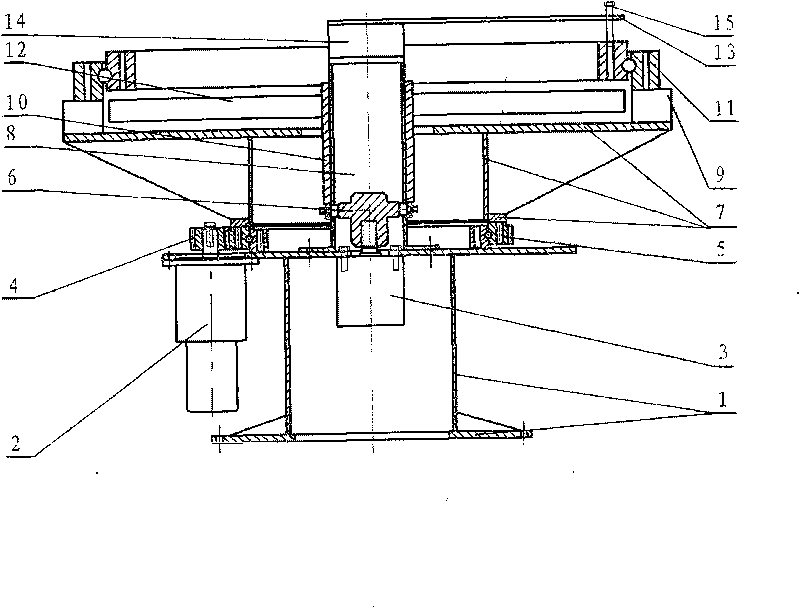

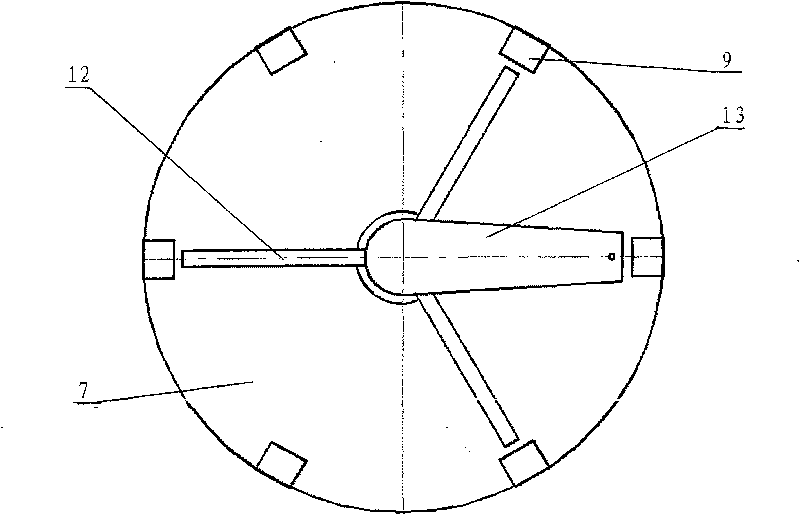

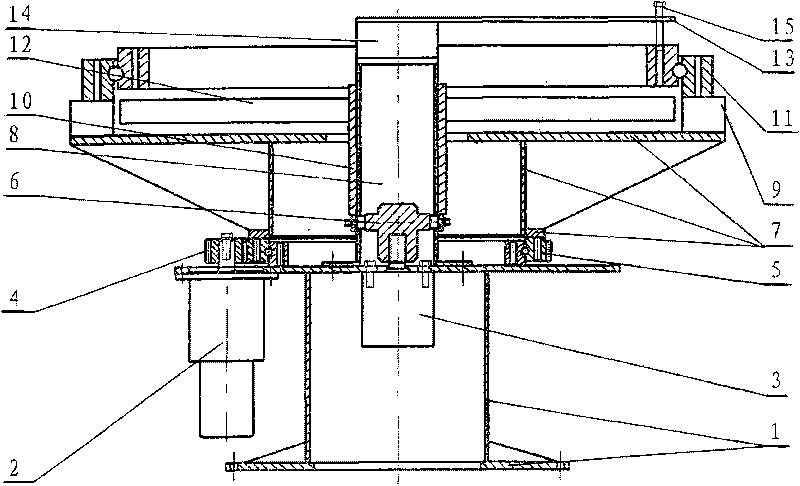

[0017] From figure 1 , figure 2 It can be seen from the figure that: an assembly and testing platform for the slewing bearing of a wind power generator is characterized in that the testing platform is mainly composed of a base 1, a reducer 2, a cylinder 3, a pinion 4, an external gear slewing bearing 5, a cross slide Block 6, detection table 7, cavity column 8, pad 9, sliding sleeve 10, bracket 12, measuring arm 13, torque sensor 14, screw rod 15 and computer; the base 1 is a hollow cylindrical steel structure, From top to bottom, it is mainly composed of a disc-shaped upper platform with a central hole, a cavity body I and an annular bottom plate I, and welded reinforcing ribs are evenly distributed around the circumference between the cavity body I and the annular bottom plate I. Install the external toothed slewing bearing 5 on the upper platform of the base 1, that is, connect the inner ring of the outer toothed slewing bearing 5 with the upper platform. In addition, a l...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap