Optical device, imaging device, method for manufacturing optical device

一种光学装置、光学部件的技术,应用在光学、光学元件、安装等方向,能够解决粘接剂变形、位置关系破坏、生产成本增加等问题,达到抑制位置关系偏离、稳定摄像性能、确保摄像性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

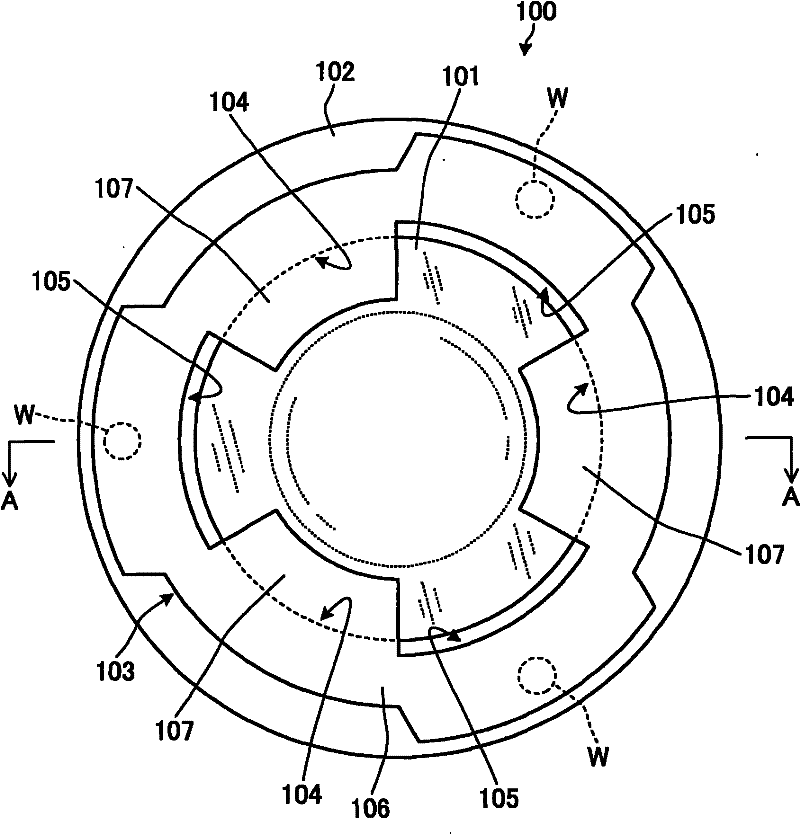

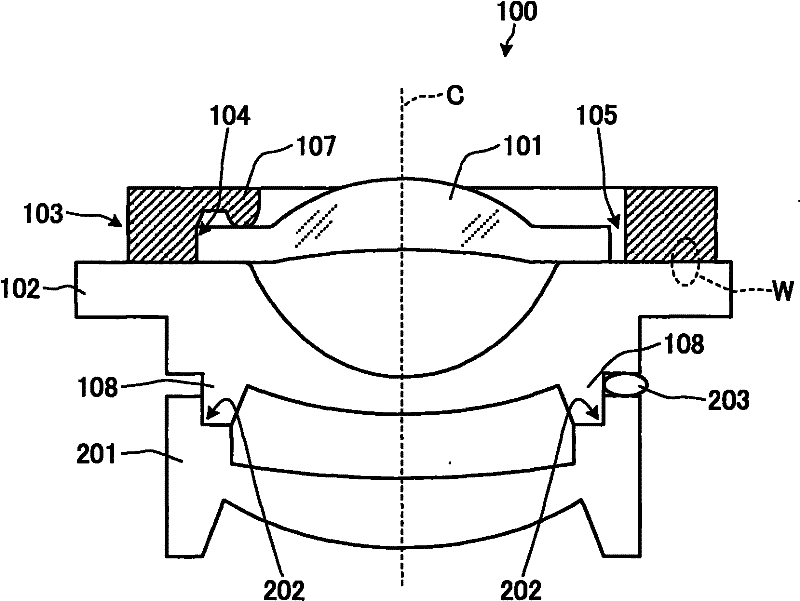

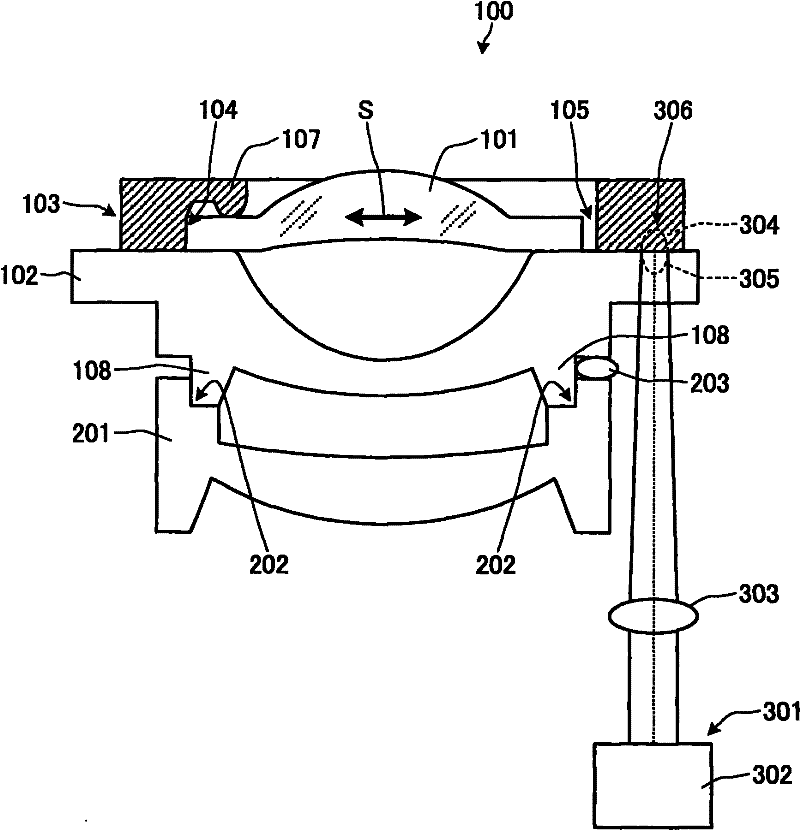

[0046] Next, preferred embodiments of the optical device and the imaging device of the present invention will be described in detail with reference to the drawings. In this embodiment, an application example to a lens device is shown as an optical device of the present invention.

[0047] First, a schematic configuration of a lens device according to an embodiment of the present invention will be described. A lens device according to an embodiment of the present invention includes a plurality of lenses as optical components. A plurality of lenses are respectively provided inside a lens barrel having a substantially cylindrical shape.

[0048] Some or all of the plurality of lenses are arranged to be relatively movable with respect to the lens barrel along the optical axis direction. The shape of the lens barrel and the movement mechanism of each lens in the lens barrel can be easily realized by known techniques, and thus description thereof will be omitted. A part of the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com