Packaging structure of multi-chip semiconductor

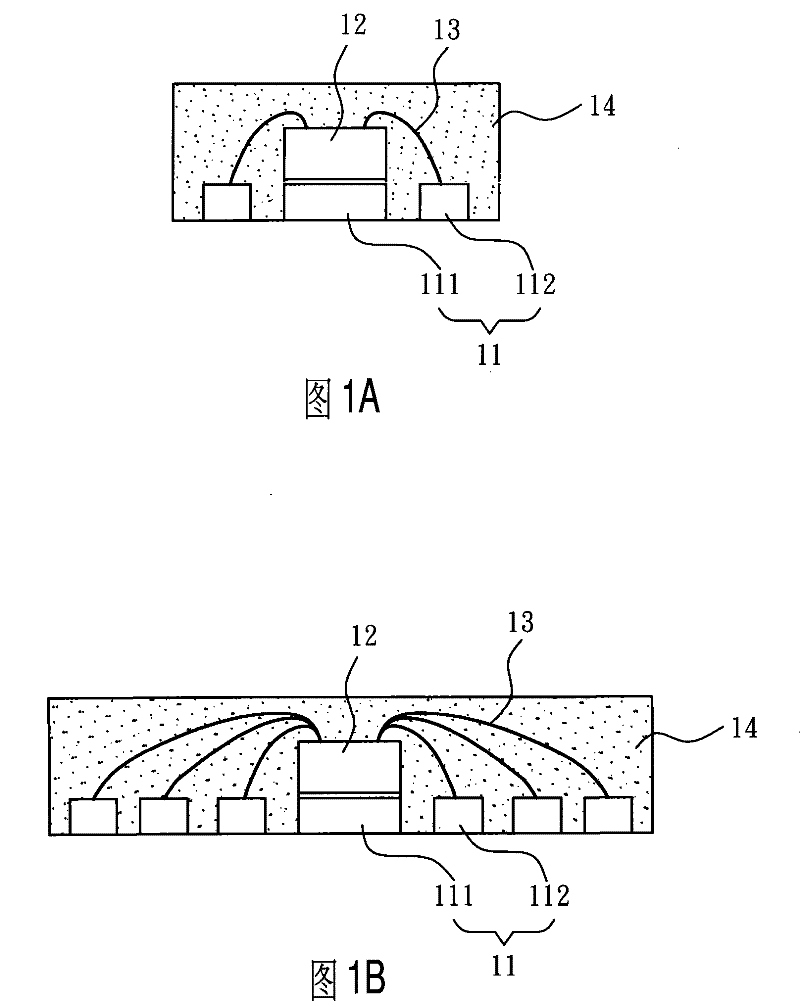

A semiconductor and multi-chip technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve problems such as improving defective products, complex, and complicated staggered arrangement of wires 13

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] This embodiment will introduce the present invention in detail with reference to the drawings. The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention may be practiced. The direction terms mentioned in the present invention, such as "up", "down", "front", "rear", "left" or "right", etc., are only referring to the directions of the attached drawings. Therefore, the directional terms used are used to assist in explaining the relevant constructions, but not to limit the present invention.

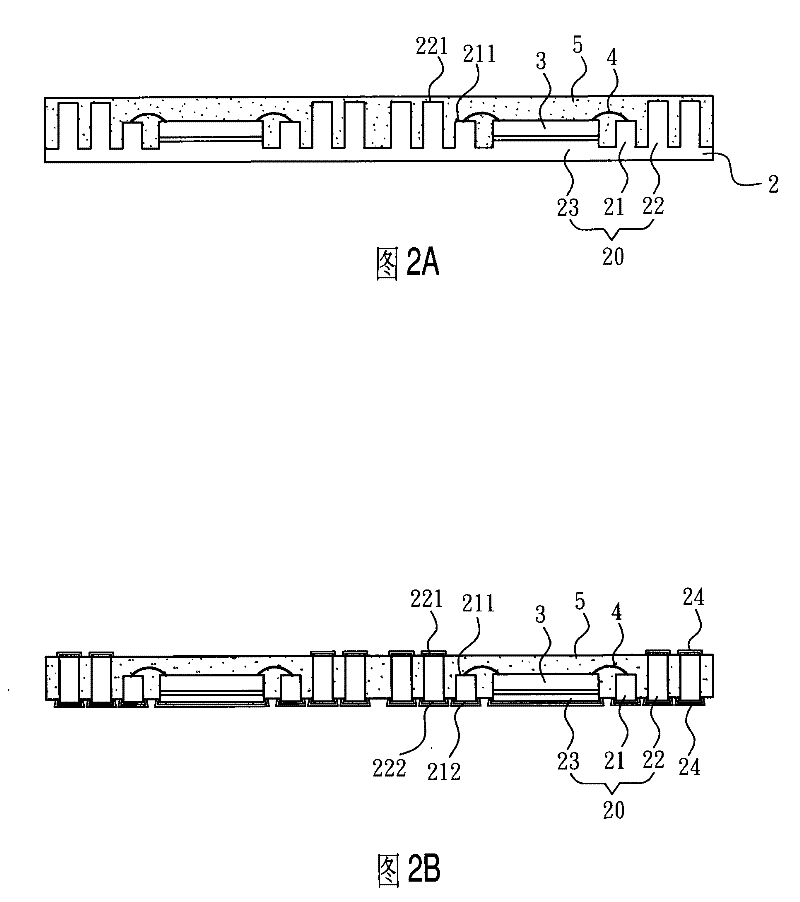

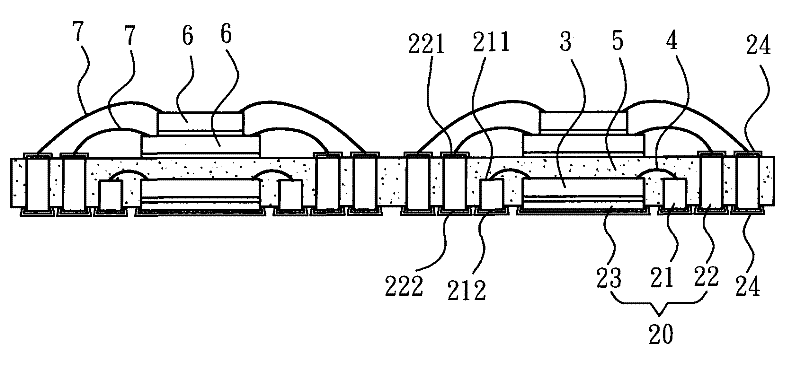

[0027] Please refer to Figure 2A , 2B , 2C, 2D and 2E, which disclose a schematic diagram of the manufacturing process of the multi-chip semiconductor package structure of the first embodiment of the present invention, which is used to illustrate the multi-chip semiconductor package structure of the first embodiment of the present invention and its possible Manufacturing method, but th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com