High thermal expansion coefficient ceramic material for high-density packaging and preparation method thereof

A ceramic material and high thermal expansion technology, which is applied in the field of high thermal expansion coefficient ceramic materials for high-density packaging and its preparation, can solve problems such as not suitable for high-density packaging, facilitate mass production and popularization and application, overcome thermal mismatch, mechanical The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with specific examples.

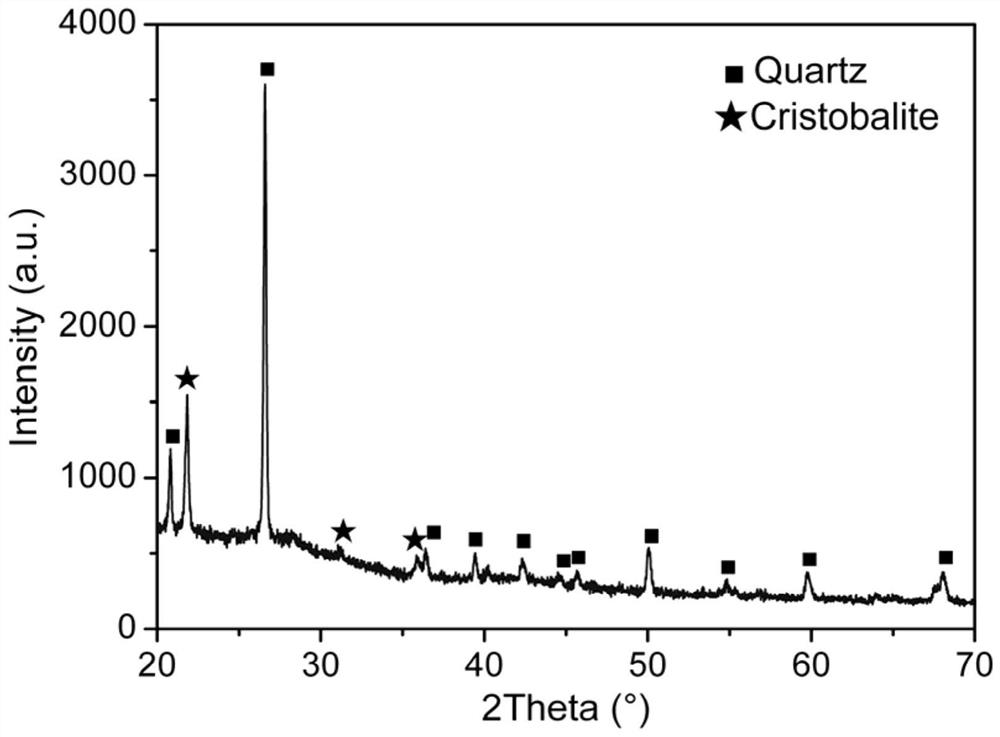

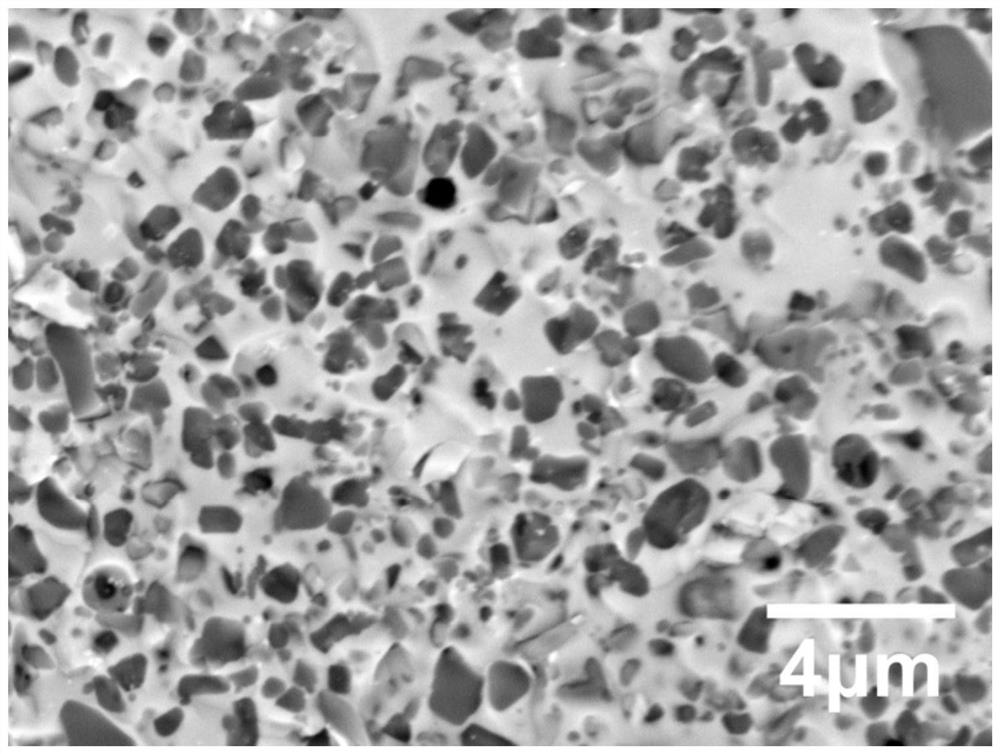

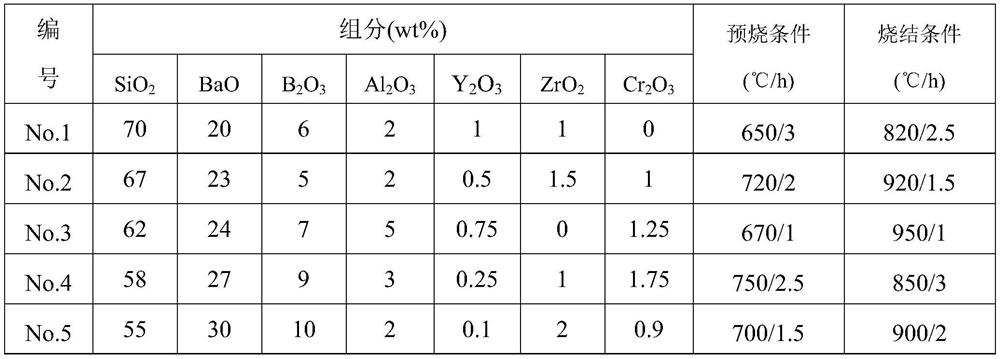

[0025] Table 1 shows the actual ratio and preparation process of each component of the low-temperature co-fired ceramic material with a high expansion coefficient in Examples 1 to 5 of the present invention, and Table 2 shows the properties of Examples 1 to 5 of the present invention; wherein Example 3 is prepared XRD diffraction analysis diagram and cross-sectional scanning electron microscope SEM diagram of low temperature co-fired ceramic material with high thermal expansion coefficient figure 1 , figure 2 shown.

[0026] The specific preparation process of high thermal expansion coefficient ceramic materials for high-density packaging is as follows:

[0027] Step 1: with barium hydroxide, boric acid, silicon dioxide, aluminum hydroxide, zirconium hydroxide, yttrium oxide, chromium oxide as raw material, carry out batching according to the described formula of specific embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com