Method for filling silicon through holes by using carbon nanotube clusters

A technology of carbon nanotubes and through-silicon vias, which is applied in the field of interconnection technology, can solve problems such as the difficulty in the number of transistors, achieve the effect of reducing size, reducing package size, and meeting high-density packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

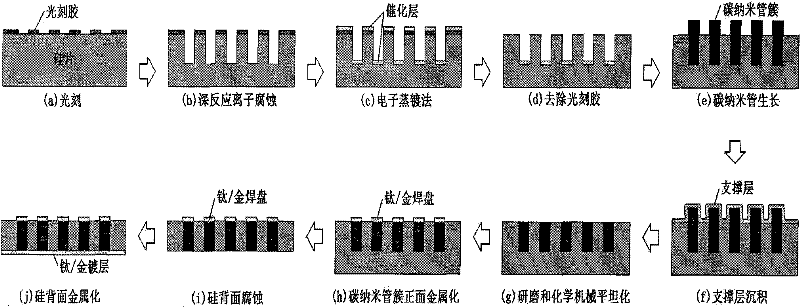

Method used

Image

Examples

Embodiment 1

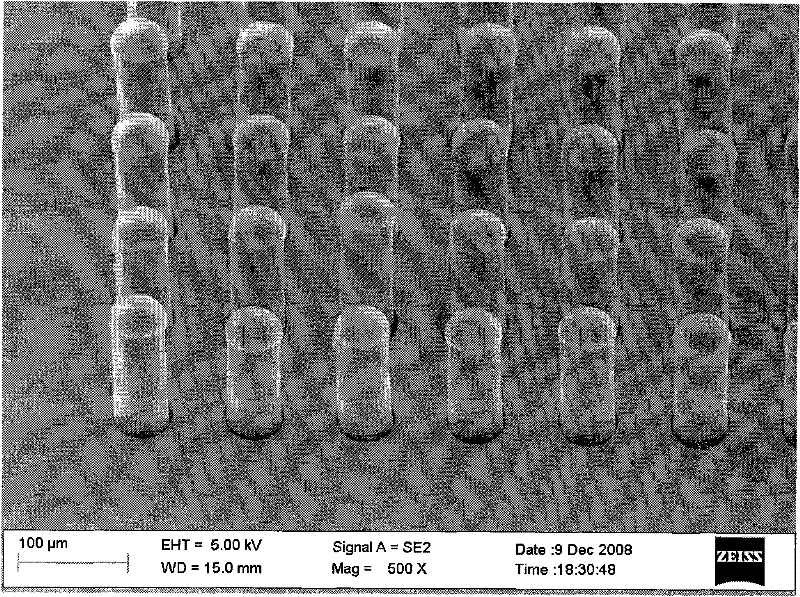

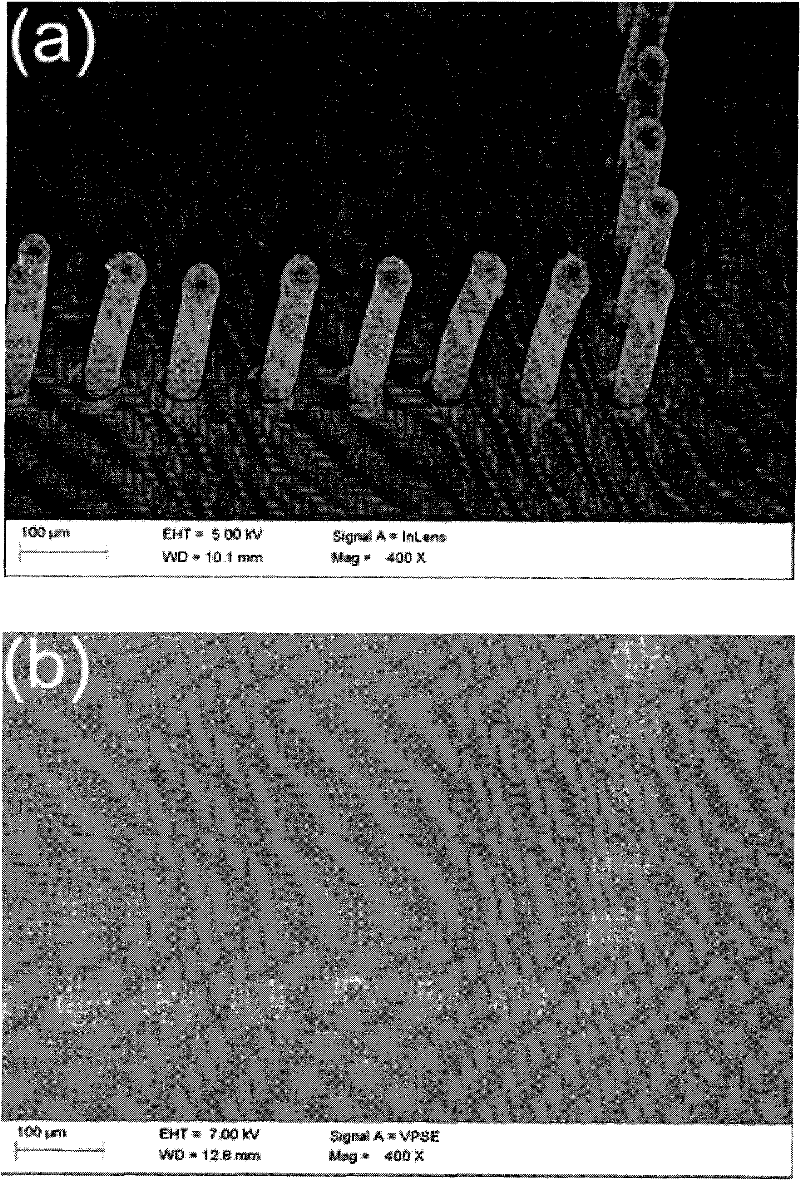

[0024] In this embodiment, the above-mentioned steps are used to prepare TSVs filled with carbon nanotube clusters, and the specific steps are as follows:

[0025] 1. First, use photolithography and deep reactive ion etching to manufacture a hole array with a diameter of 20 microns and a hole depth of 131 microns on a silicon wafer with a thickness of 7.62 cm. In the photolithography process, the photolithography covering the silicon surface The glue is not removed yet.

[0026] 2. Deposit a catalytic layer consisting of 10 nanometer thick Al2O3 and 1 nanometer thick iron on the silicon wafer by electron beam evaporation.

[0027] 3. Use isopropanone and deionized water to wash off the photoresist and the catalytic layer on the photoresist. At this time, only the bottom of the hole remains with the catalytic layer.

[0028] 4. Put the silicon wafer into a quartz tube with a diameter of 4 cm and a length of 50 cm. Argon gas of 900 sccm and hydrogen gas of 100 sccm were passed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com