Method for synchronously switching trigger timing of semiconductor valves

A synchronous switching, semiconductor technology, applied in the output power conversion device, electrical components and other directions, to achieve the effect of low hardware requirements, simple and easy switching method, and large scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

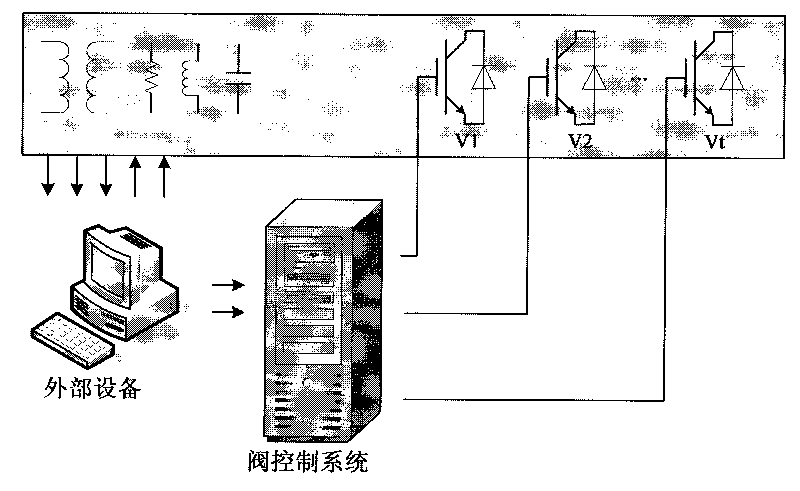

[0039] A typical large-scale power electronic device can be used figure 1 hint. Such devices usually include transformers, resistors, reactors, capacitors, semiconductor valves and corresponding control equipment. The control equipment can be divided into the valve control system specially used to trigger and shut off the semiconductor valve and the external automation equipment (referred to as external automation equipment) to complete other control and protection functions.

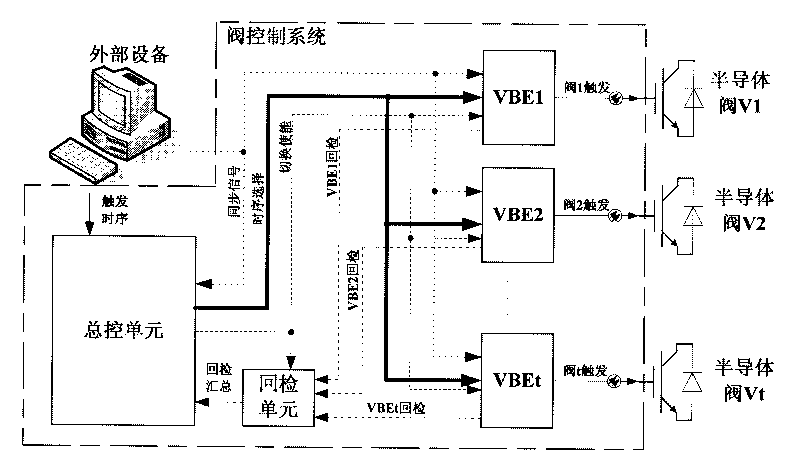

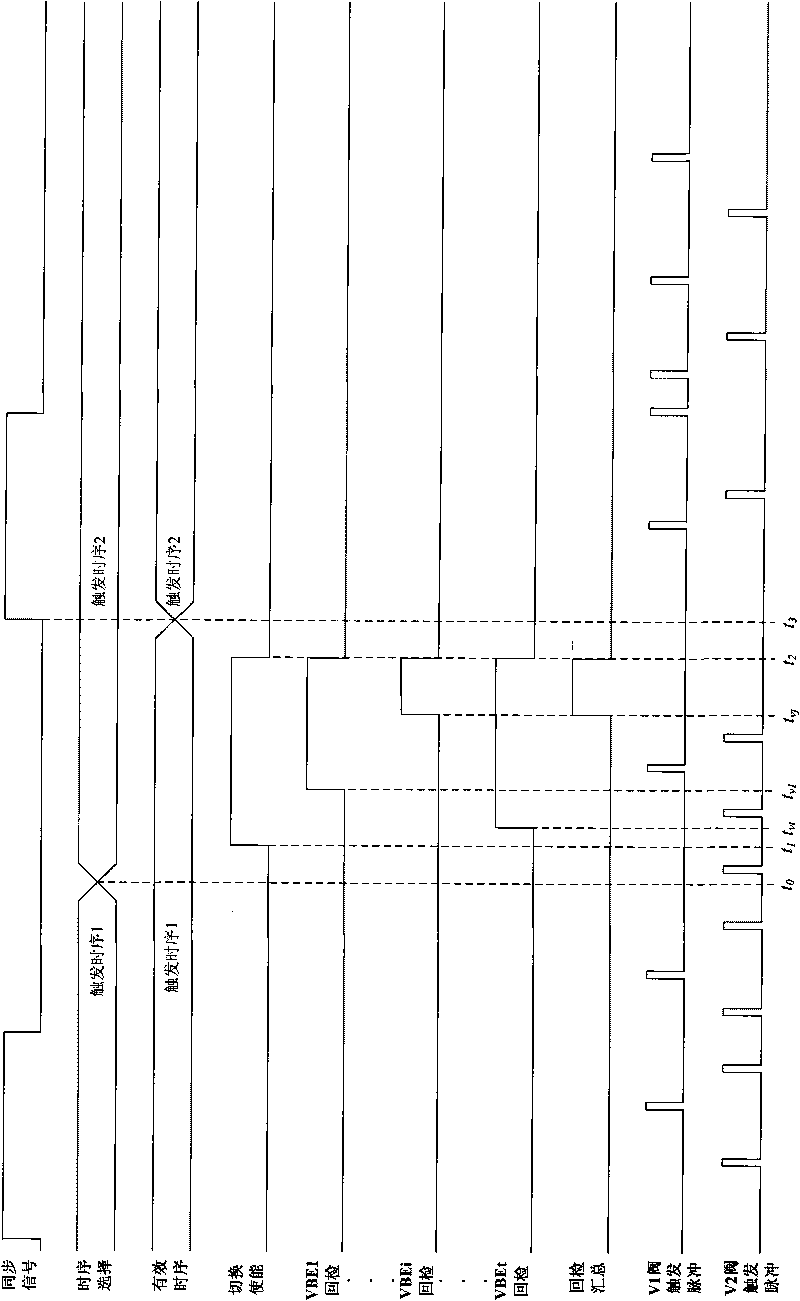

[0040] The schematic diagram of the valve control system of the present invention is as attached figure 2 shown. The system includes a master control unit, a checkback unit and a valve base electronic unit (VBE) of each semiconductor valve. The master control unit receives the "trigger timing" signal issued by the external automation equipment (external automation equipment for short), which can be any form of parallel or serial code, and is used to indicate the new trigger that each semiconductor v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com