Exhaust purification device for internal combustion engine

An exhaust purification device and technology for exhaust purification, which are applied in exhaust devices, mufflers, electrical control, etc., can solve the problems of catalyst overheating, time consumption, and fuel economy deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

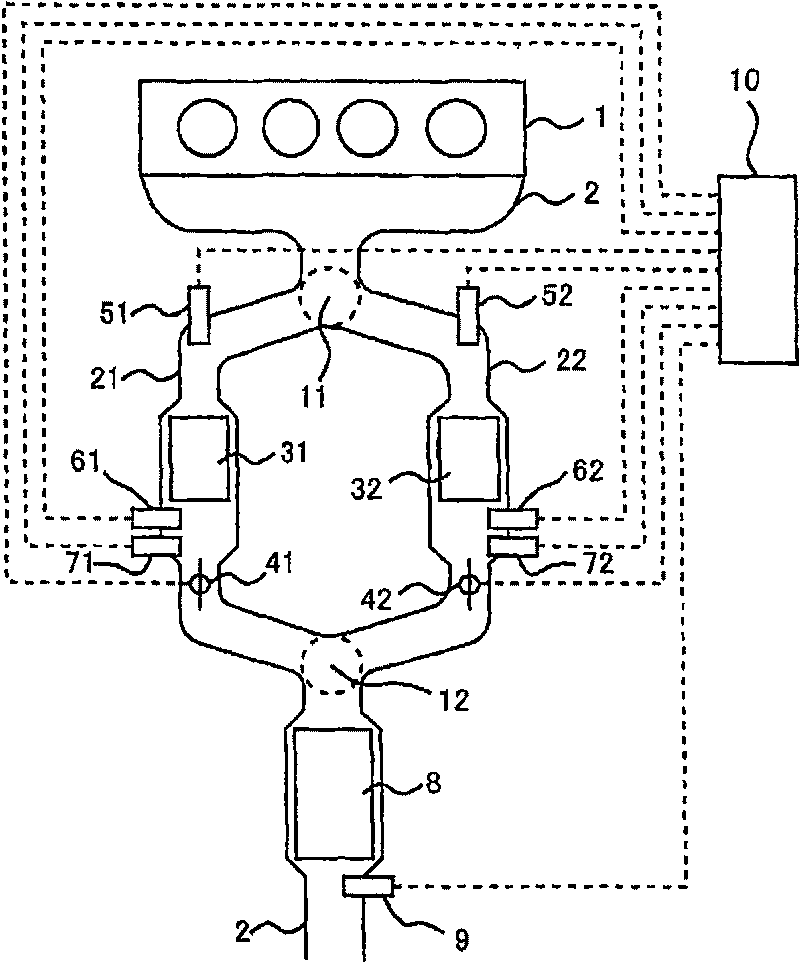

[0042] figure 1 It is a figure which shows the schematic structure of the internal combustion engine 1 and its exhaust system of this embodiment. figure 1 The internal combustion engine 1 shown in is a water-cooled four-stroke diesel engine.

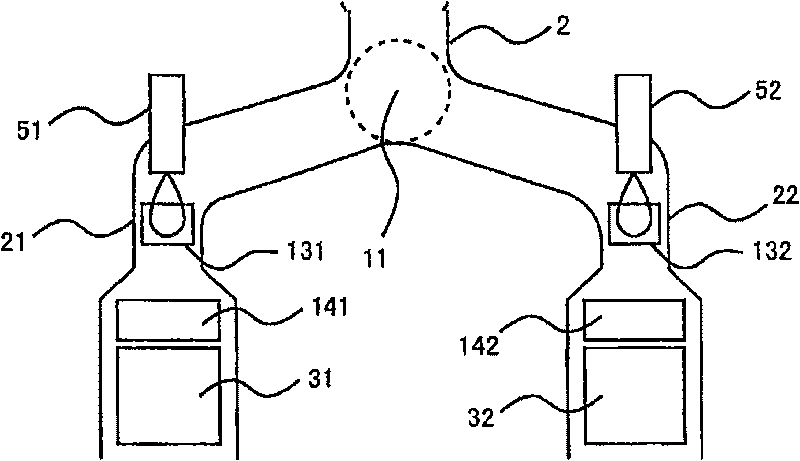

[0043] An exhaust passage 2 leading to the combustion chamber is connected to the internal combustion engine 1 . The exhaust passage 2 is branched into a first exhaust passage 21 and a second exhaust passage 22 at a branch portion 11, and the first exhaust passage 21 and the second exhaust passage 22 join at a confluence portion 12 downstream of the branch portion 11. .

[0044] In the first exhaust passage 21, a first occlusion reduction type NO x Catalyst 31 (hereinafter referred to as the first NO x catalyst). In addition, in the second exhaust passage 22, a second occlusion reduction type NO x Catalyst 32 (hereinafter referred to as the second NO x catalyst). first NO x Catalyst 31 and the second NO x The catalyst 32 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com