Method for increasing content of cocoa butter in process of producing cocoa powder

A cocoa powder and cocoa butter technology, applied in the field of food processing, can solve the problems of oil content, aroma and fragrance loss, final product quality impact, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

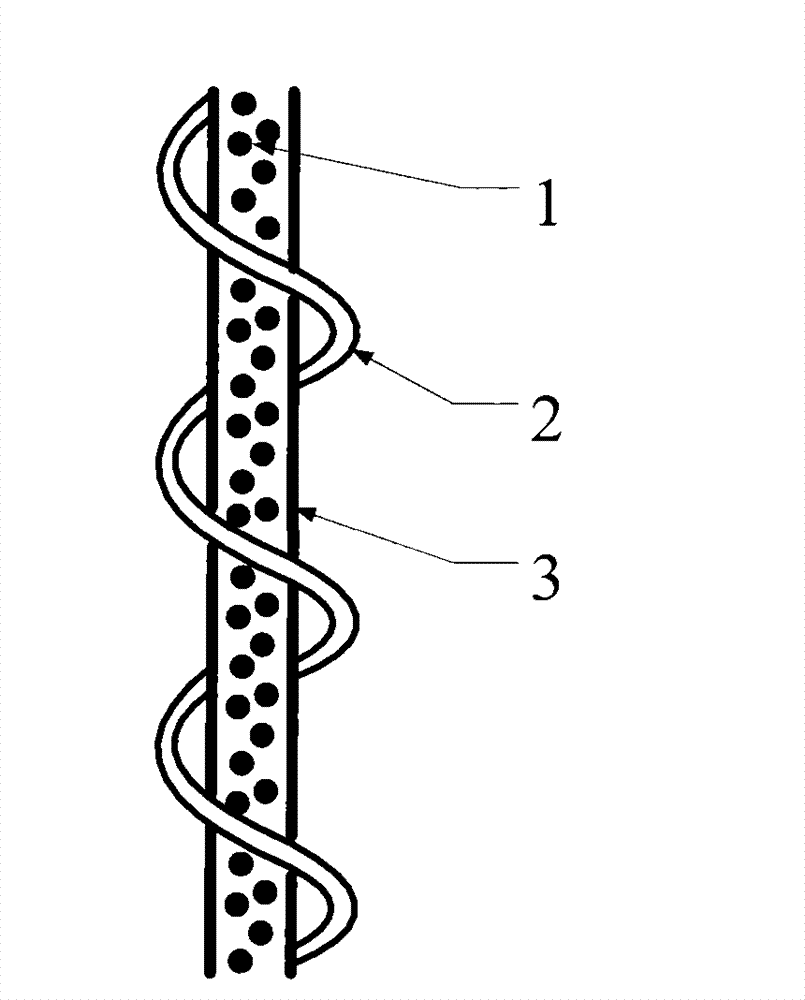

[0018] like figure 1 , After the cocoa beans are coarsely crushed, they are crushed into large cocoa powder. Due to the crushing, the temperature of the cocoa powder in the pipeline rises, and the aroma and fragrance of the oil are partially melted and heat loss occurs. After this step, a refrigeration device such as a refrigeration pipe is placed on the outside of the outlet channel, so that the coarsely crushed cocoa powder can be cooled rapidly, cocoa butter and cocoa powder particles are condensed, and the cocoa butter content in the cocoa powder particles is retained to the maximum extent, and the cocoa powder is improved. Aroma fragrance of powder. Similarly, a refrigerating pipe is also added outside the finely crushed outlet channel to achieve the effects of cooling and condensation. The refrigeration tube realizes refrigeration by utilizing the heat-absorbing property of the liquid refrigerant with a low boiling point when it vaporizes, and its advantages are conveni...

Embodiment 2

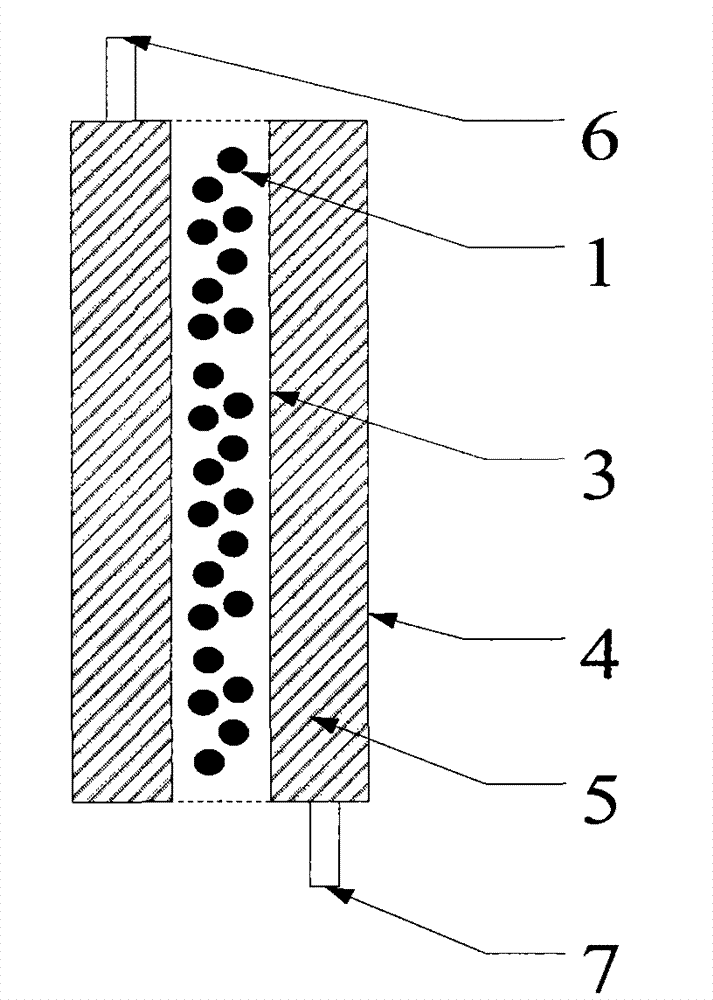

[0022] like figure 2 After the cocoa beans are coarsely crushed, they are crushed into large-grained cocoa powder. Due to the crushing, the temperature of the cocoa powder in the pipeline rises, and the aroma and fragrance of the oil are partially melted and heat loss occurs. After this step, a refrigeration device such as a refrigeration box is placed on the outside of the outlet channel. The refrigeration box is filled with flowing refrigerant liquid, and the outlet channel is placed in the refrigerant liquid, so that the coarsely crushed cocoa powder is cooled rapidly, and the cocoa butter and cocoa powder particles are condensed. , retain the cocoa butter content in cocoa powder particles to the greatest extent, and enhance the aroma and fragrance of cocoa powder. Similarly, a refrigeration box is also added outside the finely crushed outlet channel to achieve the effects of cooling and condensation. The refrigerating liquid can be a liquid refrigerant with a low boiling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com