Smashing and separating machine for kitchen rubbish

A technology of food waste and separator, which is applied in the direction of grain processing, etc., can solve difficult problems and achieve the effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

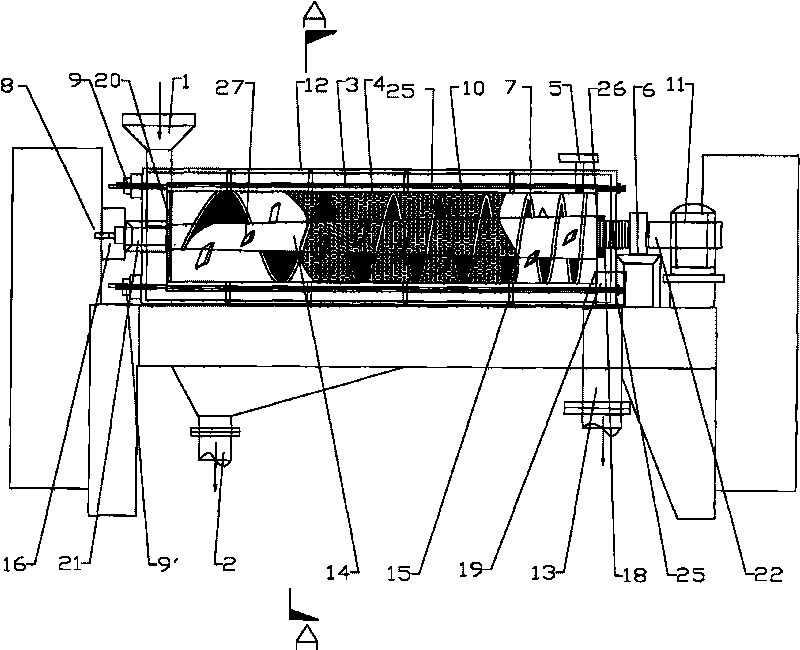

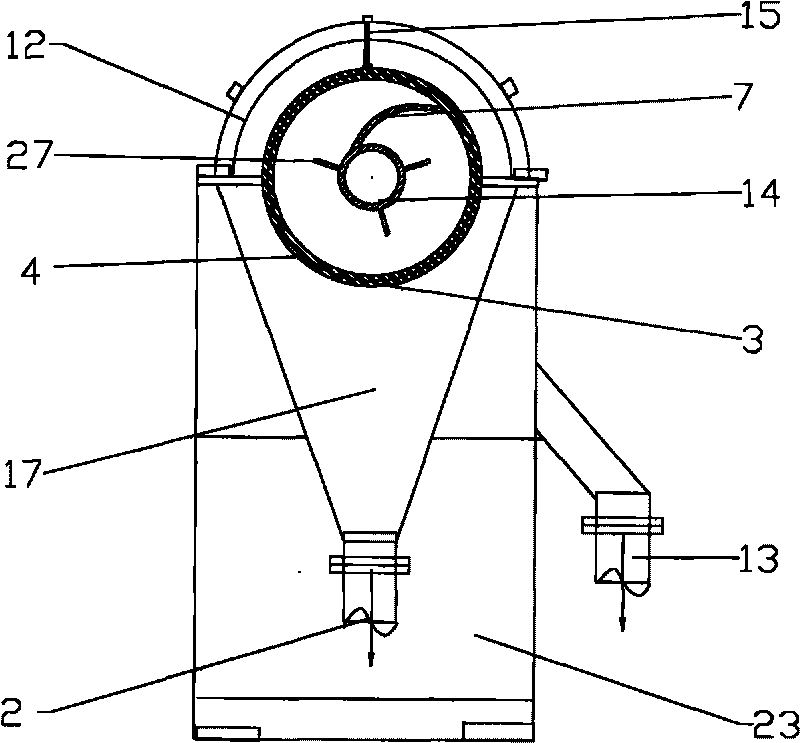

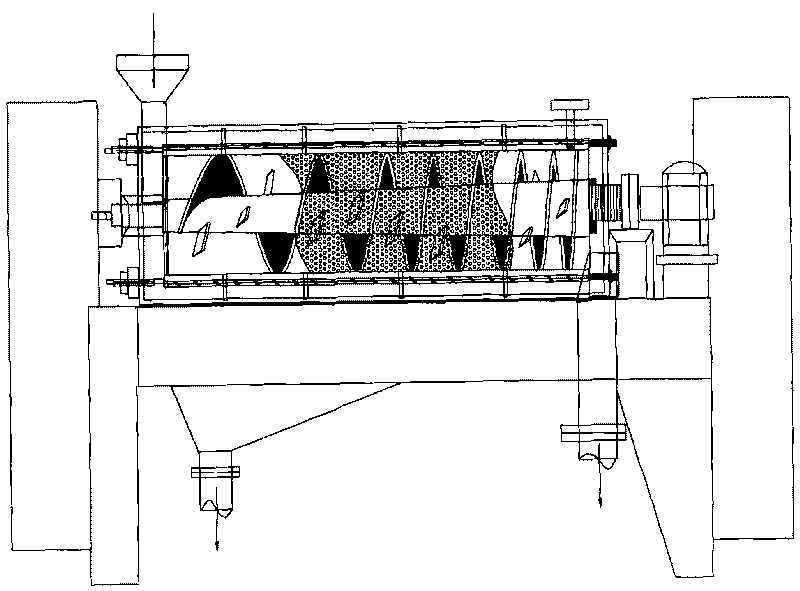

[0010] As can be seen from the accompanying drawings, the present invention includes a power assembly 10, a housing assembly 12, a cleaning pipe 5, a variable pitch screw 14, a fixed blade 27 arranged in a spiral, a pressure sleeve 3, a double-layer filter cartridge 4, an end wall 20, a filter Cylinder gap adjustment mechanism 9. The power assembly 10 includes a motor, a reducer, and a base; the housing assembly 12 includes a conical feed hopper 1, a hopper cover, a water accumulation chamber 17, a water outlet pipe 2, a slag discharge bin 19, and a slag discharge pipe 13; a variable-pitch screw 14 Front bearing seat 21 and rear bearing seat 22 are arranged at the two ends of the, and rear bearing seat 6 is connected 22 with power assembly 10 outlet shafts, and has variable pitch helical blade 7 and fixed blade 27 on the screw rod. The outer surface of the pressure-bearing sleeve 3 is equipped with a reinforcing plate 15, and the double-layer movable filter screen 10 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com