Special nano iron powder for damaging satellite through spraying

A nano-iron powder, satellite technology, applied in the coating and other directions, to achieve the effect of simple use, good attack effect, unlimited storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

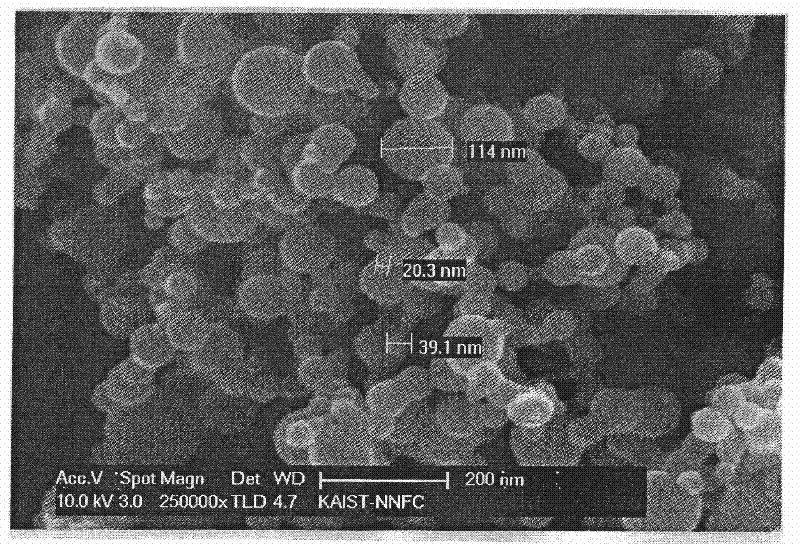

[0028] Example 1, a special nano-iron powder for satellite jet damage, (for the specific processing method, refer to the metal nano-powder zero-boundary particle cutting production process recorded in Patent Application No. 2006100481685,) the preparation method is at -5 ° C, high The number of frequency cuts is set at 4500 times per minute to produce and process nano-iron powder (the shape of the powder particle is an irregular sphere), and then separate out (125nm as an example) D3=41nmD25=62.1nm D50=125nm D75=177.2nm D97=230.3nm The powder material with relatively large particle distribution, and then continue the anti-oxidation coating with a thickness of 1nm-3nm on the iron powder particles, so that the anti-oxidation time can reach more than 90 hours.

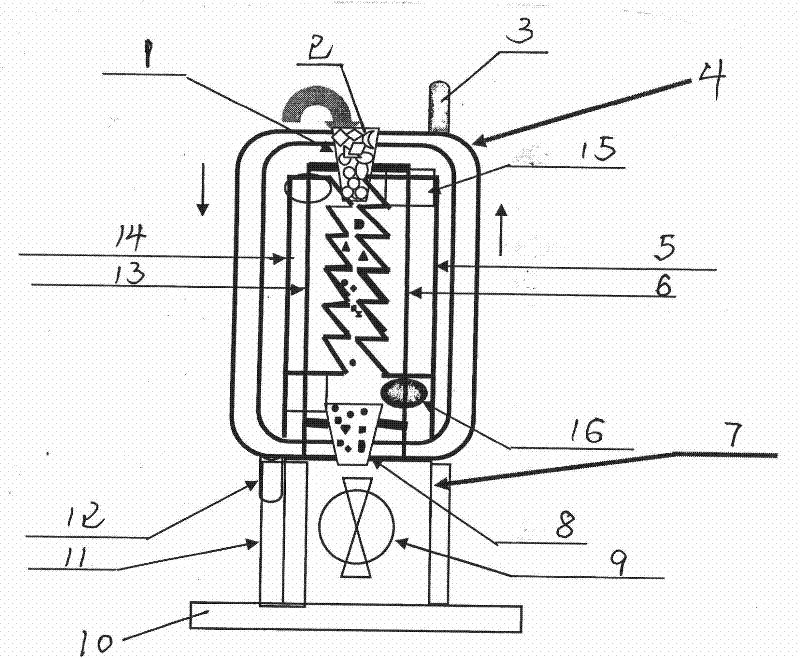

[0029] The cutting machine used is as figure 1 As shown, the cutting machine structure includes a body with a cooling system, the body is provided with a feed port 2, an inert gas inlet 1, and several cutting knife group...

Embodiment 2

[0033] Example 2, a special nano-iron powder for satellite jet damage, the preparation method is to produce and process it under the condition of -10 ℃, and the frequency of high-frequency cutting is set at 5500 times per minute (the shape of the powder particles is not Regular sphere) nano-iron powder, and then sort out (125nm as an example) powder materials with relatively large particle distribution of D3=41nm, D25=62.1nm, D50=125nm, D75=177.2nm, D97=230.3nm, and then use "DQ package "Coating method" continues the anti-oxidation coating on the iron powder particles with a thickness of 1nm-3nm, so that the anti-oxidation time can reach more than 90 hours.

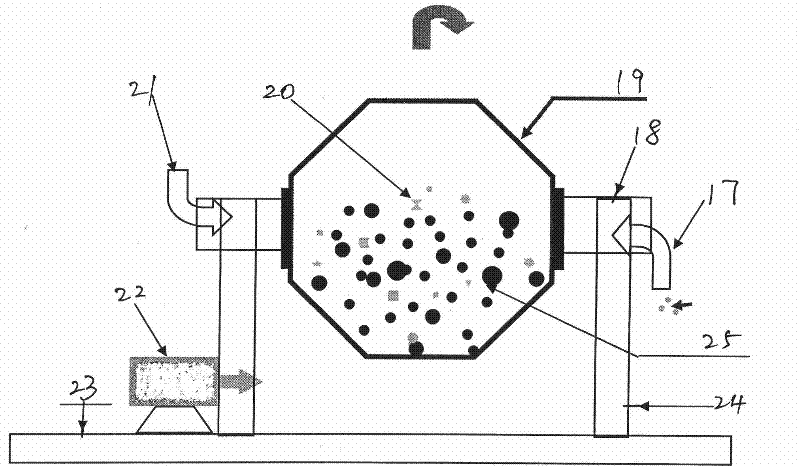

[0034] According to the characteristics of the technology used, the coated powder material is input into a high-speed grinder for surface treatment of the powder particles to make the surface of the powder particle material rough and uneven.

Embodiment 3

[0035] Example 3, a special nano-iron powder for satellite jet damage, the preparation method is to produce and process it under the condition of -7°C and set the frequency of high-frequency cutting at 5000 times per minute (the shape of the powder particles is not Regular sphere) nano-iron powder, and then sort out (125nm as an example) powder materials with relatively large particle distribution of D3=41nm, D25=62.1nm, D50=125nm, D75=177.2nm, D97=230.3nm, and then use "DQ package "Coating method" continues the anti-oxidation coating on the iron powder particles with a thickness of 1nm-3nm, so that the anti-oxidation time can reach more than 90 hours.

[0036] According to the characteristics of the technology used, the coated powder material is input into a high-speed grinder for surface treatment of the powder particles to make the surface of the powder particle material rough and uneven.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com