Crankshaft flange eccentric hole clamp for drill

An eccentric hole and crankshaft technology, used in boring/drilling, drilling/drilling equipment, clamping, etc., can solve the problems of long production cycle, high tooling cost, low processing efficiency, etc., to shorten the manufacturing cycle, Low manufacturing cost and good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

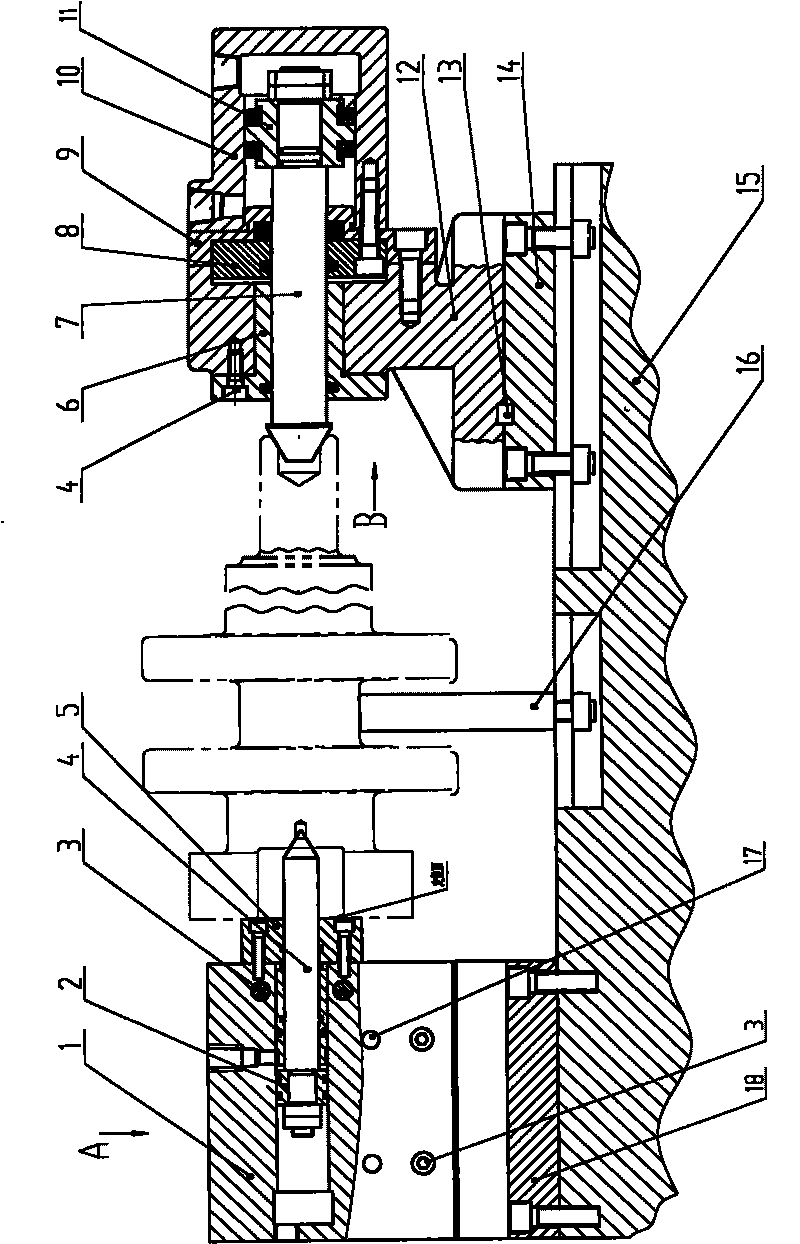

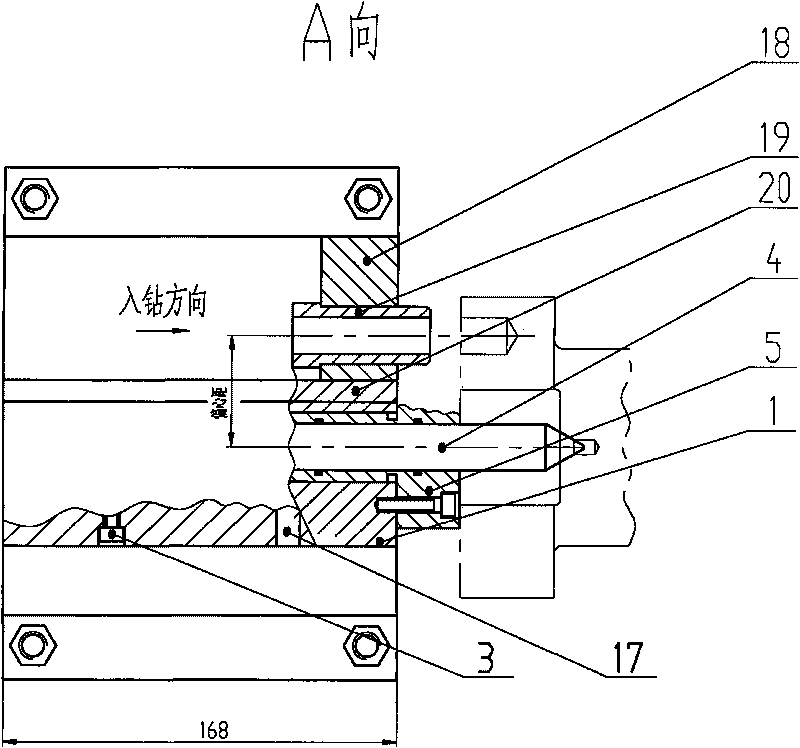

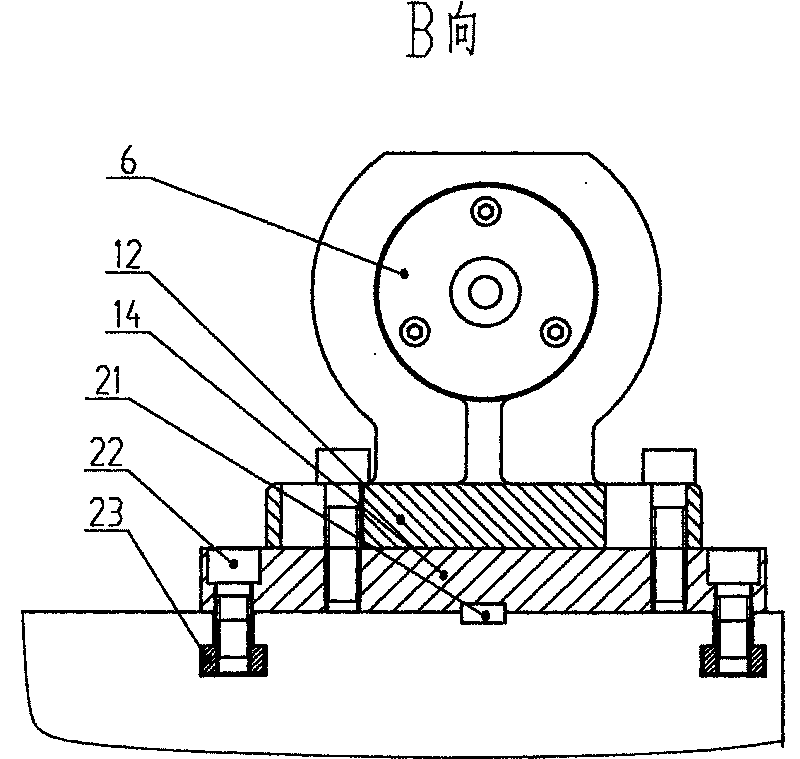

[0016] From figure 1 , figure 2 It can be seen that a fixture for drilling eccentric holes in crankshaft flanges includes a clamp body 16, a positioning column 17, a headstock mechanism, and a tailstock mechanism, and the clamp body 16 is installed on a horizontal drilling machine.

[0017] The head frame mechanism of the present invention is provided with guide sleeve 5, head frame oil cylinder 1, piston rod 4, piston 2, bolt 3, positioning pin 17, adjustment pad 20, fixed support 18, drill sleeve 19. One side of the headstock oil cylinder 1 is connected with the adjustment pad 20, and is fixed on the fixed support 18 with the bolt 3 and the positioning pin 17. The drill sleeve 19 is also mounted on the fixed support 18 for drilling guidance. The fixed support 18 is fixed on the clip body 15 . The guide sleeve 5 is installed on the headstock oil cylinder 1. One end of the piston rod 4 is installed with the piston 4, and the other end passes through the guide sleeve 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com