Solid-wood composite floor board with vertical tenons and production process thereof

A technology for a solid wood composite floor and a production method, which is applied in the field of wood floors and solid wood floors, can solve problems such as easy arching and warping, and achieve the effects of improving compression resistance, elegant appearance and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

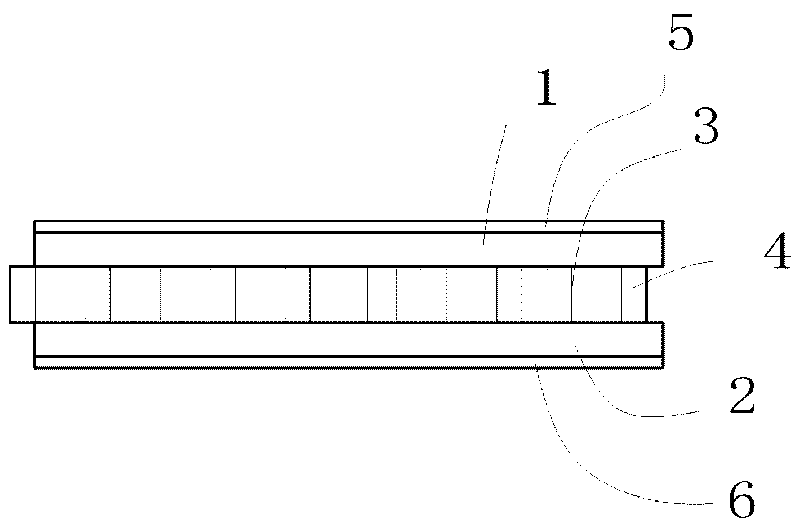

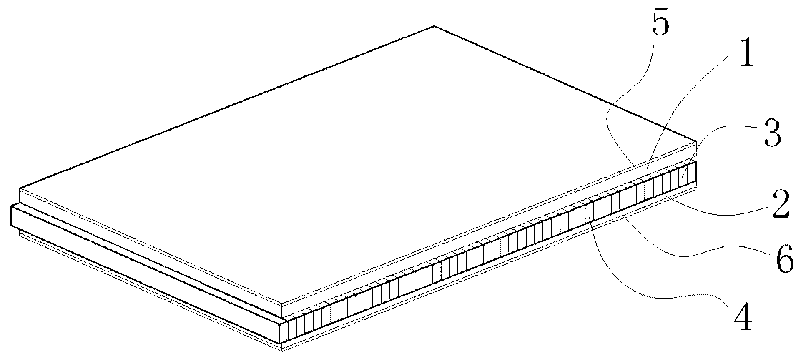

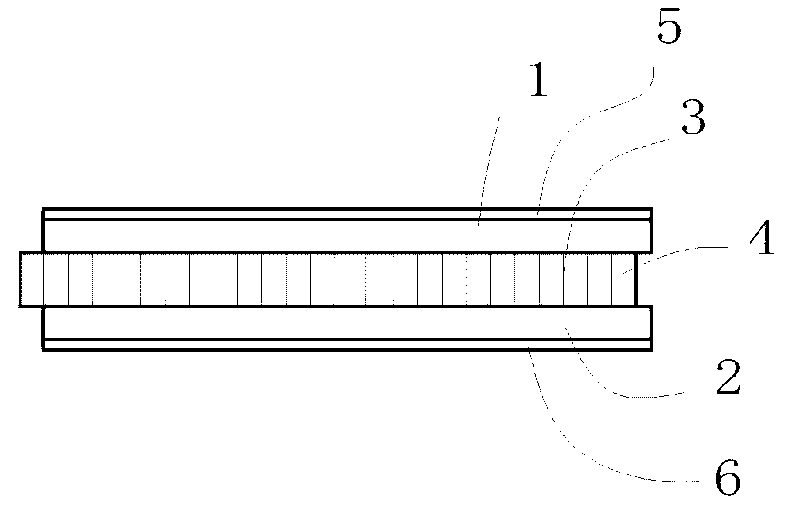

[0023] A vertical tenon solid wood composite floor, as attached figure 1 And attached figure 2 As shown, the composition includes a surface plate 1, a bottom plate 2 and a core plate 3. A finish layer 5 is provided above the surface plate 1. The finish layer 5 is made of precious veneer with a thickness of 2 mm. A balance layer 6 is provided below the bottom plate 2. , the balance layer 6 can be any tree species, the balance layer 6 and the facing layer 5 are symmetrically arranged, and the symmetrical arrangement means that the balancing layer is arranged symmetrically according to the quality and shape of the facing layer; Composition of pasting; the surface plate 1 and the bottom plate 2 are composed of 5 plain boards pasted staggeredly. The bottom plate 2 is composed of 5 square plain plates 5 with a thickness of 1.2mm; the surface plate 1 and the bottom plate 2 are composed of 5 square plain plates 5 with a thickness of 1.2mm; The wooden strips 4 are formed by sticking...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com