Pressure glue dipping system for laying layer of subsequent technique of composite material pultrusion product

A composite material, pressure dipping technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

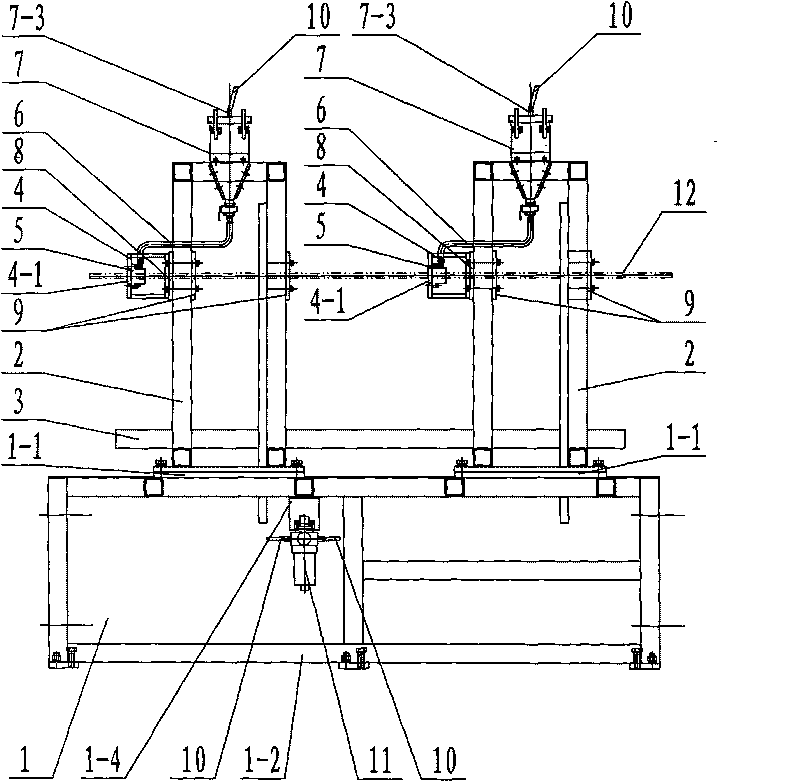

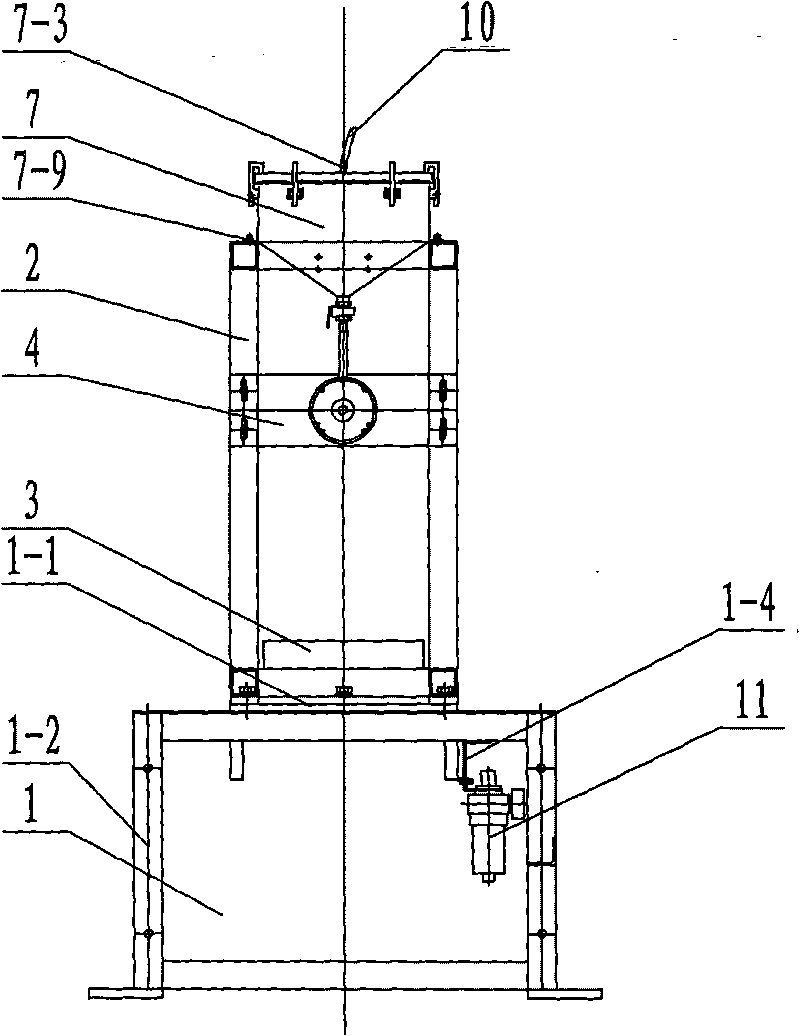

[0007] Specific implementation mode one: combine figure 1 with figure 2 To illustrate this embodiment, the pressurized rubber dipping system for subsequent process layup of composite pultrusion products in this embodiment includes a chassis 1, two support frames 2, two dipping ring supports 4, two pressurized dipping Ring 5, two rubber hoses 6, two pneumatic pressure rubber tanks 7, four tooling plates 9, two pressure air pipes 10 and a compressed air pressure adjustment valve 11; two supporting frames are installed side by side on the bottom frame 1 2. A dipping ring bracket 4 is installed on each of the two supporting frames 2, and each of the two dipping ring brackets 4 has a passage hole 4-1, and the passage holes 4-1 on the two dipping ring brackets 4 The axes are on the same horizontal line, and each of the two dipping ring brackets 4 is equipped with a pressurized dipping ring 5, and the axes of the two pressurized dipping rings 5 are on the same level as the axis p...

specific Embodiment approach 2

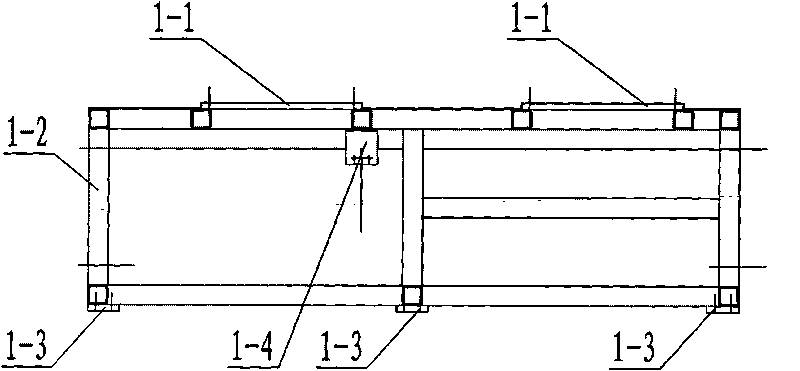

[0008] Specific implementation mode two: combination figure 1 with Figure 3-Figure 5 To illustrate this embodiment, the underframe 1 of this embodiment is composed of two supporting frame connecting plates 1-1, an underframe main body 1-2, a plurality of anchor plates 1-3 and a pneumatic regulating valve connecting plate 1-4, the underframe The main body 1-2 is a rigid structural frame welded by steel profiles and steel plates. The two support frame connecting plates 1-1 are installed side by side on the upper end surface of the chassis main body 1-2. The two support frames 2 are supported by The frame connecting plate 1-1 is connected with the chassis main body 1-2, the lower end of the chassis main body 1-2 is equipped with an anchor plate 1-3, and the compressed air pressure regulating valve 11 is connected to the bottom frame body 1-4 through the pneumatic regulating valve connecting plate 1-4 Installed inside the chassis main body 1-2. The function of such setting is t...

specific Embodiment approach 3

[0009] Specific implementation mode three: combination Figure 6-Figure 7 To illustrate this embodiment, each support frame 2 in this embodiment is a rigid structural frame welded from top to bottom by a support frame main body 2-1 and a connecting bottom plate 2-2. The role of such arrangement is to support components such as the dipping ring support 4 and the pressurized dipping ring 5 of the dipping system. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com