Ship ballast water treatment method and discharge reactor

A technology of ship ballast water and discharge reaction, which is applied to the treatment device of ship ballast water and the field of ship ballast water treatment, and can solve the problems of limited water volume and small contact area between discharge electrodes and ballast water to be treated, etc. , to achieve the effect of reducing loss and uniform and sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in more detail below in conjunction with accompanying drawing example:

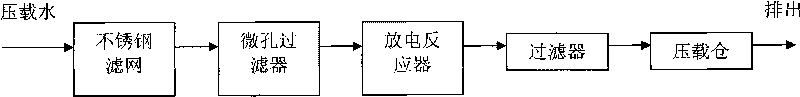

[0030] combine figure 1 A flow chart of the method is described in detail. The ballast water passes through the stainless steel filter in turn to remove large suspended pollutants and suspended algae in the water, and then reaches the microporous filter for filtration and enters the discharge reaction device. The residence time of the ballast water in the reaction device is 0.1 to 2 hours. The ballast water after discharge discharge treatment enters the ballast tank through the filter at the outlet of the discharge device.

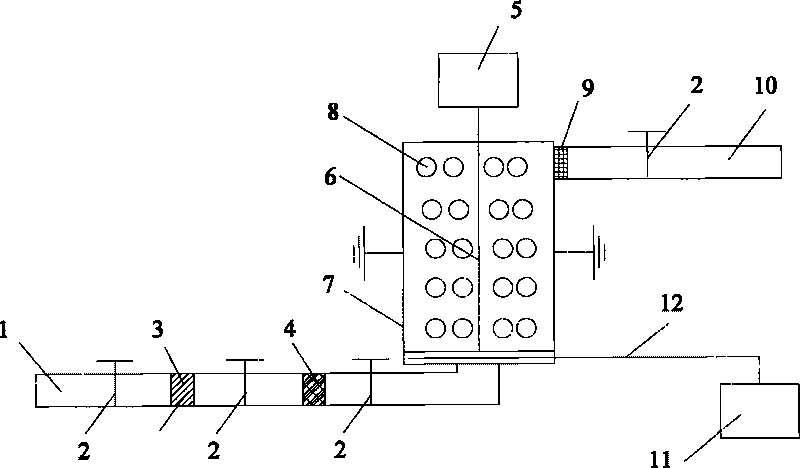

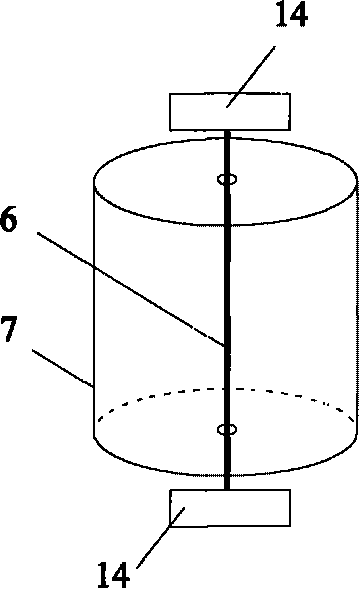

[0031] combine figure 2 and image 3 . The ballast water sequentially passes through the water inlet 1, passes through the valve 2, reaches the stainless steel filter 3, removes large suspended pollutants and suspended algae in the water, and then reaches the microporous filter 4 for filtration, the filter hole is 20-50 microns, and ent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com