Method for absorbing and separating refinery catalytic dry gas by adopting oil

A technology for oil absorption and refinery, applied in the direction of adsorption purification/separation, organic chemistry, etc., can solve the problems of high energy consumption and large investment, and achieve the effect of low energy consumption, low investment and increased ethylene production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

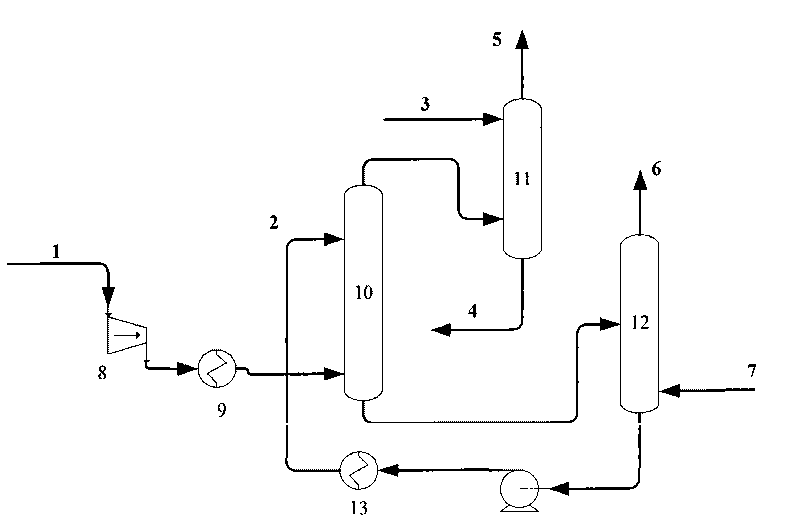

Image

Examples

Embodiment 1

[0050] The composition of catalytic dry gas, C4 absorbent and naphtha in a refinery is shown in Table 1.

[0051] Table 1

[0052]

[0053]

[0054] The above-mentioned catalytic dry gas is separated by adopting the oil absorption method of the present invention to separate the refinery catalytic dry gas process.

[0055] The specific process is:

[0056] The catalytic dry gas from the catalytic cracking unit of the refinery, with a pressure of 0.8MPa, enters the compressor 8 and undergoes three-stage compression to increase the pressure to 4.8MPa. The pressurized dry gas is cooled to 10°C by the cooler 9, and then sent into the main absorption tower 10. In the main absorption tower, the etherified C4 produced by the refinery (see Table 1 for the specific composition) is used as the absorbent 2, which is injected from the top of the tower to absorb the C2 fraction and heavier components in the dry gas. The theoretical plate number of the main absorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com