Ultrahigh chromium cast grinding ball and heat treatment process thereof

A technology of casting grinding balls and ultra-high chromium, which is applied in the field of wear-resistant materials, can solve the problems of large difference in hardness between surface and core, high cost of ultra-high chromium casting balls, uneven hardness of grinding balls, etc. The effect of uniform hardness, uniform internal and external hardness, and reduced probability of breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]

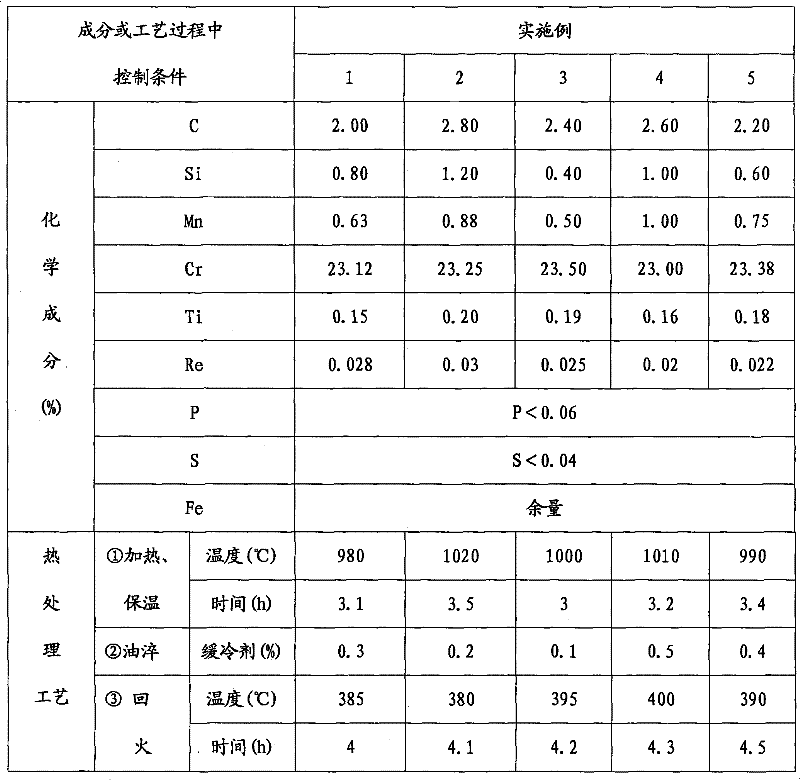

[0022] Example 1-Example 5 are respectively an ultra-high chromium cast grinding ball ZQCr26, the percentages of the respective chemical components are shown in the above table, all of which are casted by conventional metal mold casting technology.

[0023] In embodiment 1-embodiment 5, its heat treatment process is carried out according to the following sequence of steps respectively through the ultra-high chromium cast grinding ball ZQCr26 casting of cast molding:

[0024] (1) Heating and heat preservation: put the cleaned ultra-high chromium casting grinding ball ZQCr26 casting into a high-temperature resistance furnace, heat it to the corresponding temperature, and heat it for a corresponding time; then

[0025] (2) Oil quenching: Take it out from the high-temperature resistance furnace and put it into the quenching oil to cool, and the temperature drops below 200°C to discharge the oil, wherein an appropriate amount of polyvinyl alcohol is added to the quenchin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

| wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com