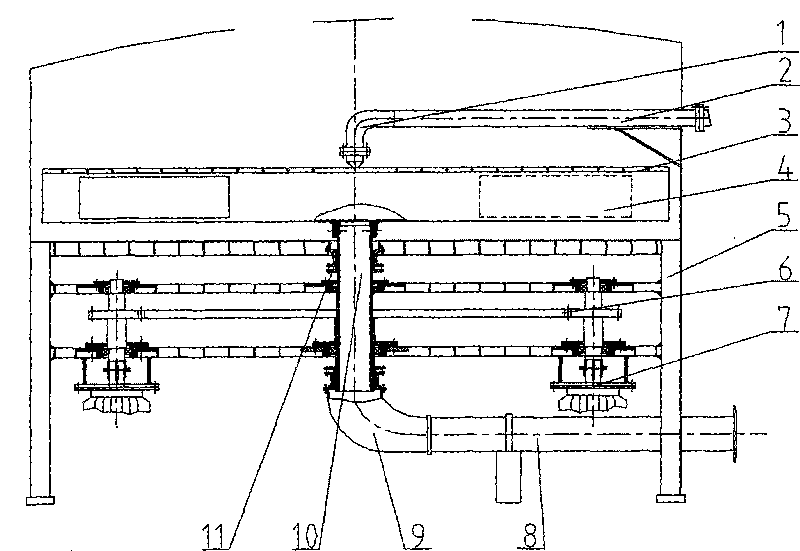

High-consistency paper pulp bleaching tower bottom discharger

A pulp bleaching and unloader technology, applied in pulp bleaching and other directions, can solve the problems of wasting materials, high motor power, and height increase, and achieve the effects of high efficiency, large bearing capacity, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

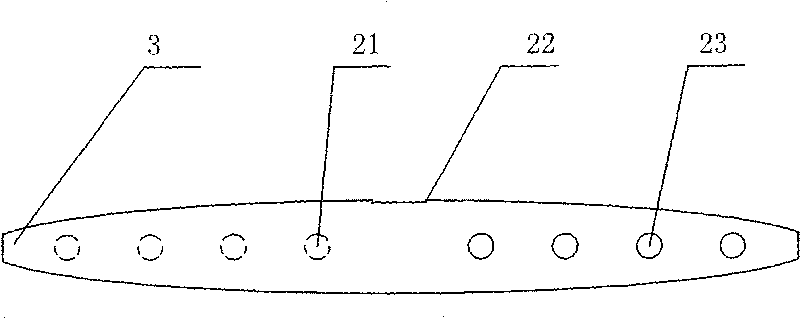

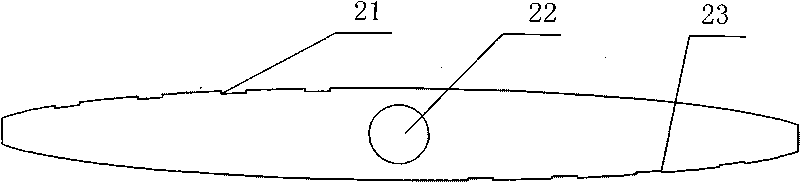

[0038] An existing high-consistency pulp downflow bleaching tower with a diameter of ¢2000mm (output 50t / d) has been used for hydrogen peroxide bleaching. The concentration of high-consistency pulp is 25-35%, and the residence time in the tower is 2- 3 hours, the bleaching temperature is 60-80°C, the unloader is composed of 2-3 rake arms and a screw, the root of the rake arm is very thick, it is a waste of material, and the power consumption is large, the power is 22.5kw, In order to obtain thin pulp, there is also a dilution system consisting of a dilution tank and a centrifugal pump below it. Now after removing the previous scraping unloader and dilution system, the unloader composed of the spindle-shaped water spray pipe, S-shaped rake arm, rotating slurry pipe, planetary gear transmission mechanism, centrifugal pump, etc. of the present invention is adopted, wherein each The power of the motor driven by the planetary wheel is 3kw, and the outlets of 8 water spray pipes are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com