Air electrode of zinc-air battery

An air electrode, zinc-air battery technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of low current density, low production cost, and high price, achieve simple operation, reduce electrode production cost, and prevent agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

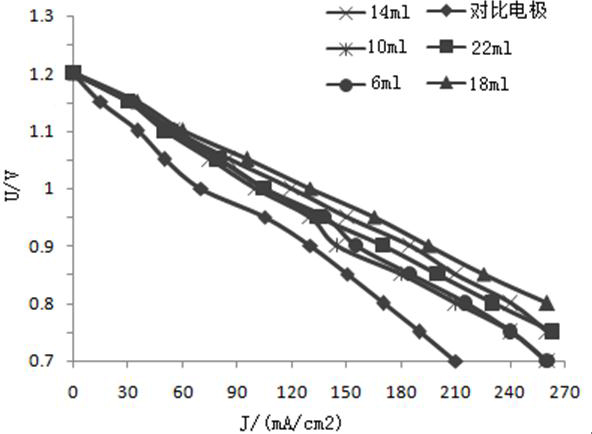

[0019] Treat 5 g of activated carbon with dilute nitric acid with a volume concentration of 10%, filter, wash with distilled water for several times, dry at 90°C, grind, pass through a mesh (400 mesh sieve) to prepare the treated activated carbon, and cool to below 5°C; TiCl at ℃~5℃ 4 Slowly inject the solution into the treated activated carbon, and keep stirring until no white acid mist escapes, the hydrolysis is completed, the reaction product is calcined at 400°C, cooled to room temperature, and ground to obtain the TiO 2 / AC Catalyst. Among them, TiCl 4 For analytical purity, the dosages are 6ml, 10ml, 14ml, 18ml, and 22ml respectively. Through conversion, the corresponding mass ranges are 10.36g, 17.26g, 24.16g, 31.07g, and 37.97g.

[0020] Take 20% by weight of the above five catalysts, 47% of carbon materials (activated carbon and acetylene black, the preferred weight ratio is 6:1), 10% of polyethylene glycol, 8% of absolute ethanol and 15% of The polytetrafluoroethy...

Embodiment 2

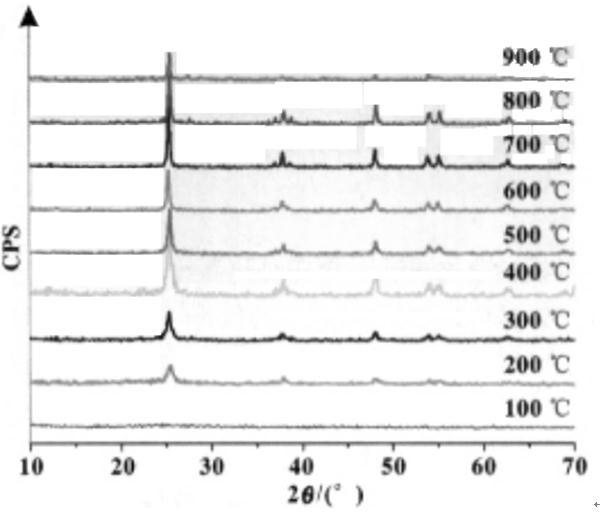

[0022] Treat 5g of activated carbon with dilute nitric acid with a volume concentration of 10%, filter, wash with distilled water several times, dry at 90°C, grind, and pass through a mesh (400 mesh sieve) to prepare the treated activated carbon, cool to below 5°C; pipette 0 18ml of TiCl at ℃~5℃ 4 The analytically pure solution was slowly poured into the treated activated carbon, and kept stirring until no white acid mist escaped, and the hydrolysis was completed. , Calcined at 500°C, 600°C, 700°C, 800°C, 900°C, cooled to room temperature and ground to obtain TiO 2 / AC catalyst samples. The XRD analysis of the sample was carried out on the D / MAX-3B rotating target X-ray powder diffractometer, and the XRD patterns at different calcination temperatures are as follows figure 2 As shown, it can be seen from the figure that: TiO below 400°C 2 The crystal growth is not perfect, and the perfect anatase type with structural activity cannot be formed; it shows the highest catalytic...

Embodiment 3

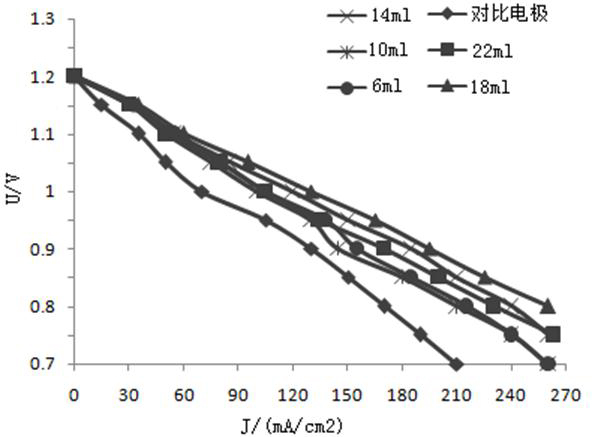

[0024] Treat 5g of activated carbon with dilute nitric acid with a volume concentration of 10%, filter, wash with distilled water several times, dry at 90°C, grind, and pass through a mesh (400 mesh sieve) to prepare the treated activated carbon, cool to below 5°C; pipette 0 18ml of TiCl at ℃~5℃ 4 Slowly pour the analytically pure solution into the treated activated carbon, and keep stirring until no white acid mist escapes, and the hydrolysis is completed. The reaction product is calcined at 400°C, cooled to room temperature, and ground to obtain the TiO 2 / AC Catalyst.

[0025] Take 5% by weight of the above catalyst, 75% of carbon material (activated carbon and acetylene black with a weight ratio of 6:1), 10% of absolute ethanol and 10% of polytetrafluoroethylene mixed and rolled to form a catalytic layer ; Take 35% carbon material by weight (activated carbon and acetylene black with a weight ratio of 6:1), 5% polyethylene glycol, 5% absolute ethanol and 55% polytetrafluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com