Double-coil four-string restrict constant current steel chord self-excited excitation circuit

A technology of exciting circuits and double coils, applied in the direction of using electric/magnetic devices to transmit sensing components, etc., can solve problems such as low frequency, electromagnetic interference oscillation, and the effect of obtained frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

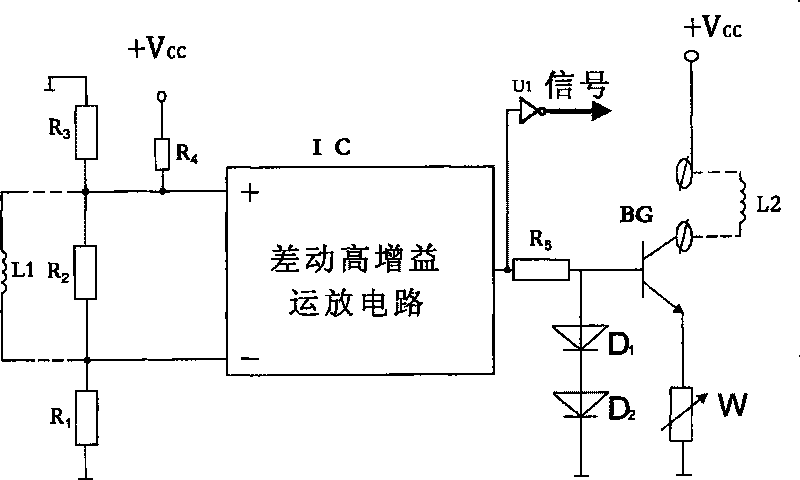

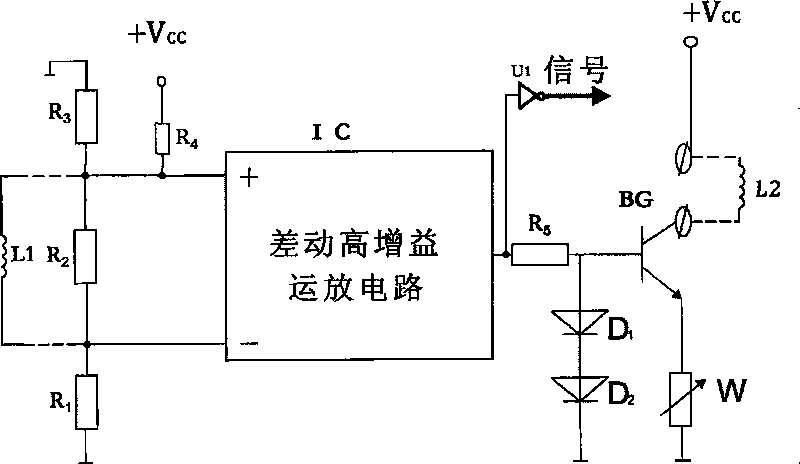

[0014] The present invention will be further described below in conjunction with the drawings:

[0015] The electrical schematic diagram of the embodiment of the present invention is shown in the figure. The supply voltage is, for example, a 5V DC / DC isolation converter single power supply, the common terminal is 0V, and Vcc=5V. The sensor's induction coil L1 is connected to the input end of the differential high gain operational amplifier circuit through a pair of twisted pairs, R 1 R 2 R 3 Is the resistance attenuation network, R 2 Both ends are connected to the input end of the op amp, and its function is to attenuate differential mode interference; R 2 , R 3 One end is connected to the non-inverting input end and the inverting input end of the op amp, and the other end is connected to the common end to attenuate common mode interference. Resistance R 5 , Series silicon diode D 1 D 2 Connected to the base of the silicon transistor BG, the emitter of the BG is connected with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com