Novel reduced-vacuum implantation dose compensation method for ion implantation apparatus

An ion implanter and compensation method technology, applied to discharge tubes, electrical components, circuits, etc., can solve the problems of poor vacuum, inaccurate implant dose measurement, and inaccurate ion implant dose.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

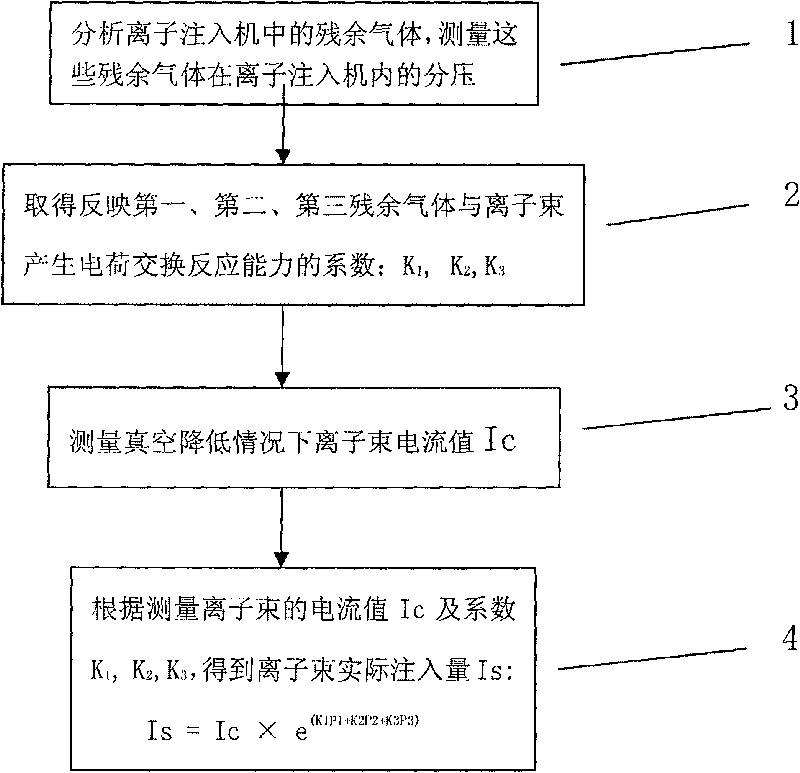

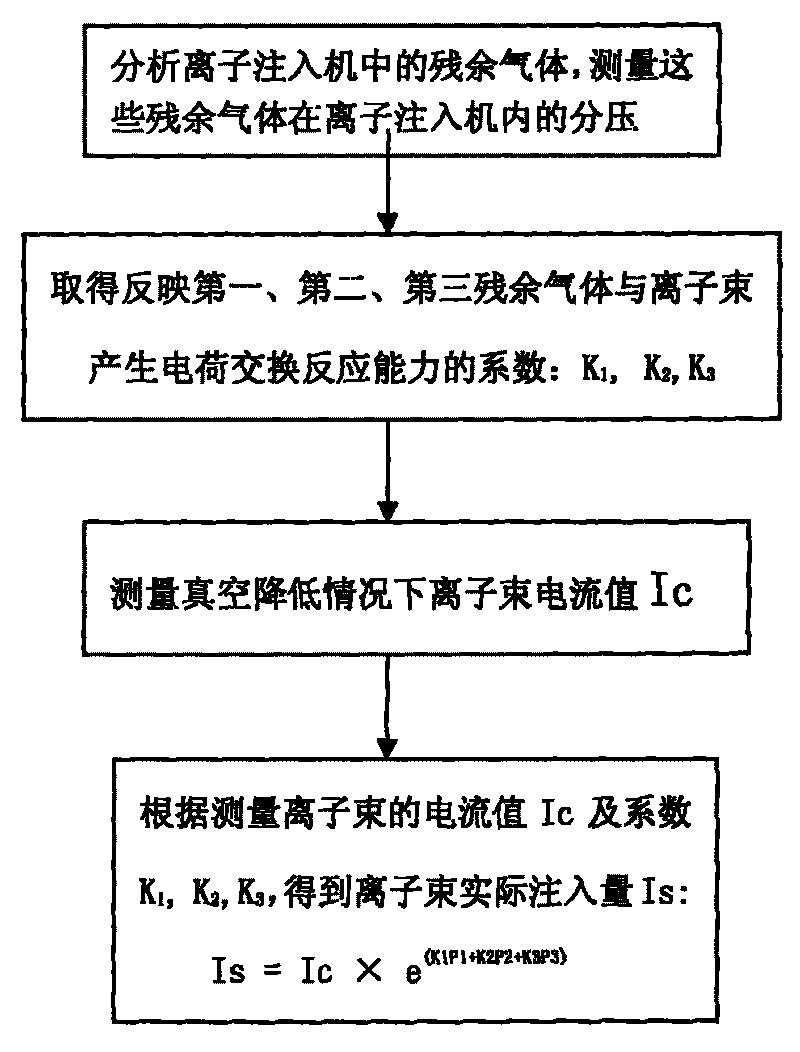

[0018] refer to figure 1 , The flow of the new compensation method for ion implanter vacuum reduction implantation dose metering includes four steps 1, 2, 3, and 4.

[0019] First, step 1 is carried out, using a residual gas analyzer to analyze the residual gas in the ion implanter to obtain the type of residual gas remaining in the ion implanter, and these residual gases are different from those injected during the previous ion implantation process gas, such as nitrogen, carbon dioxide, oxygen, nitrogen, water vapor or hydrogen, etc. And measure the partial pressure value of the above residual gas in the ion implanter.

[0020] Then, carry out step 2, the constant K of each residual gas (such as the constant K1 of the first residual gas, the constant KZ of the second residual gas and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com