Communication joint among hydraulic support controller shelves

A technology of controller frame and hydraulic support, which is applied in the direction of preventing wrong connection, device for joining/disconnecting connected parts, base/housing, etc. It can solve the problems of contact terminal corrosion, poor signal transmission quality, and water vapor intrusion of communication joints Moisture and other problems, to avoid wrong installation and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

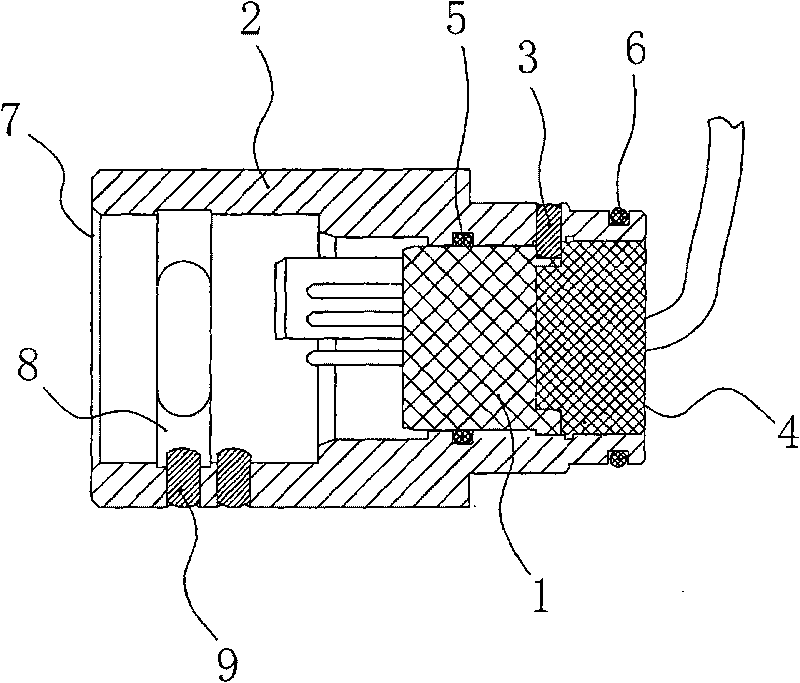

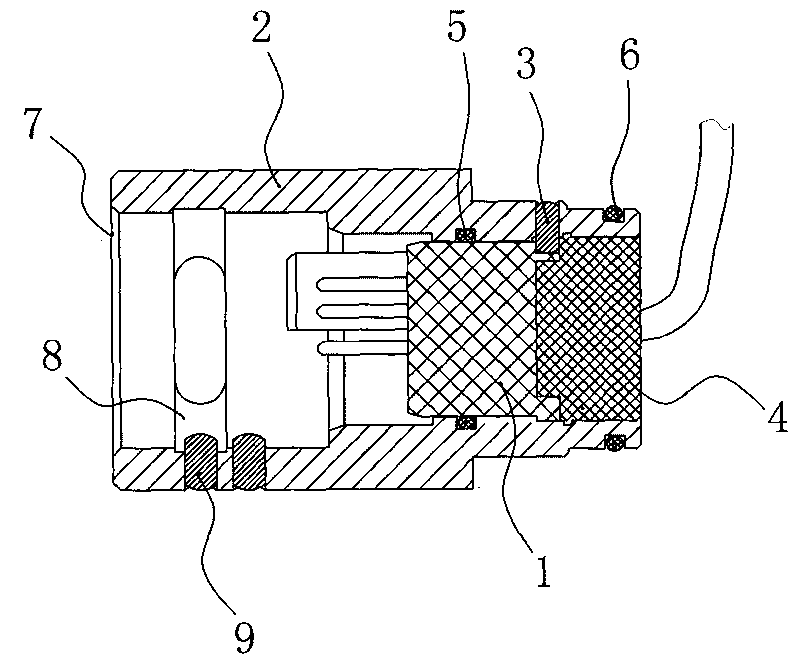

[0011] like figure 1 As shown, the hydraulic support controller inter-rack communication joint of the present invention includes a connector 1, and the connector 1 is arranged in a cylindrical joint 2 and positioned by a positioning pin 3; in the cylindrical joint 2 A potting glue 4 is provided in the cavity at the inlet end of the connector 1, and the potting glue 4 seals and fixes the cylindrical joint 2 and the connector 1; between the cylindrical joint 2 and the connector 1 and the cylindrical The outer peripheral surface of the joint 2 is provided with sealing rings 5 and 6 respectively; a fixed hole groove 8 is opened on the inner peripheral surface of the cylindrical joint 2 close to the socket 7, and a positioning hole and a positioning hole are opened on the peripheral surface of the fixed hole groove 8. The alignment pin 9 in it.

Embodiment 2

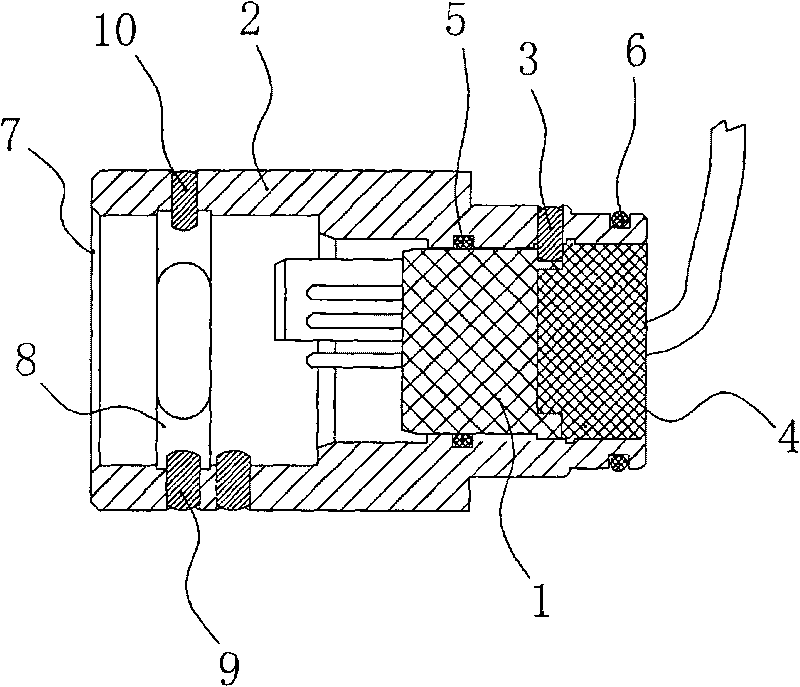

[0013] like figure 2 As shown, the hydraulic support controller inter-rack communication joint of the present invention includes a connector 1, and the connector 1 is arranged in a cylindrical joint 2 and positioned by a positioning pin 3; in the cylindrical joint 2 A potting glue 4 is provided in the cavity at the inlet end of the connector 1, and the potting glue 4 seals and fixes the cylindrical joint 2 and the connector 1; between the cylindrical joint 2 and the connector 1 and the cylindrical The outer peripheral surface of the joint 2 is provided with sealing rings 5 and 6 respectively; a fixed hole groove 8 is opened on the inner peripheral surface of the cylindrical joint 2 close to the socket 7, and a positioning hole and a positioning hole are opened on the peripheral surface of the fixed hole groove 8. The alignment pin 9 in it. In order to distinguish the left and right joints and avoid incorrect installation during use, a mark hole and a mark pin 10 placed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com