High-voltage generator used for X-ray machine and control method thereof

A high-voltage generator and X-ray machine technology, applied in the field of X-ray machines, can solve the problems of expensive high-voltage cables, difficult insulation design, and large switching loss, so as to facilitate movement and assembly, reduce work loss, and reduce loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

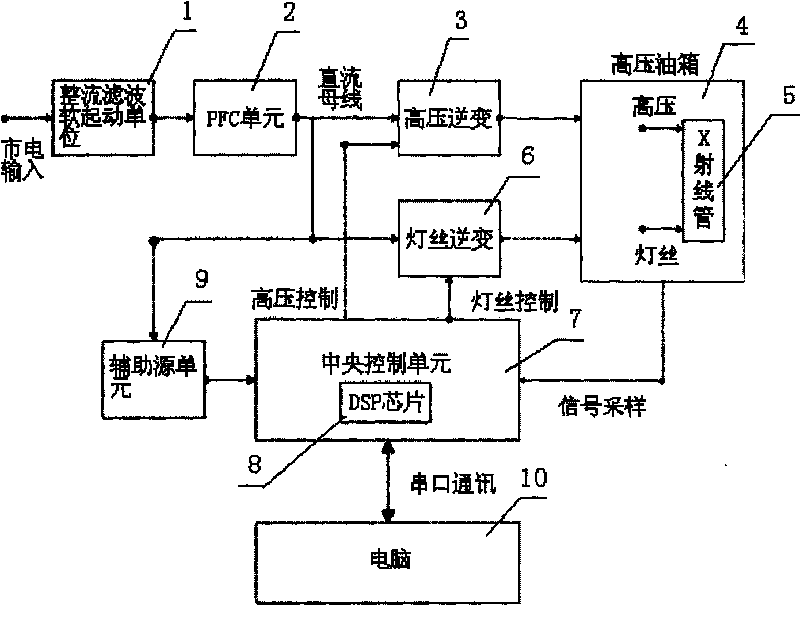

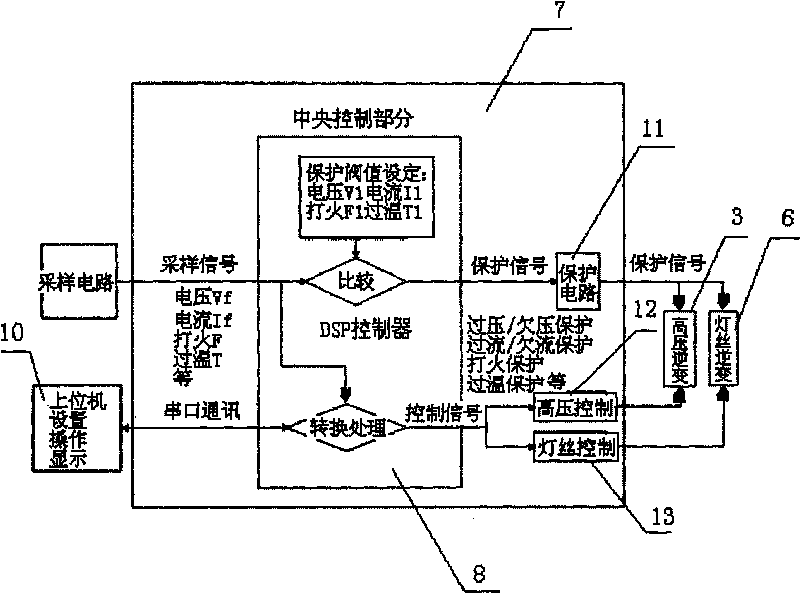

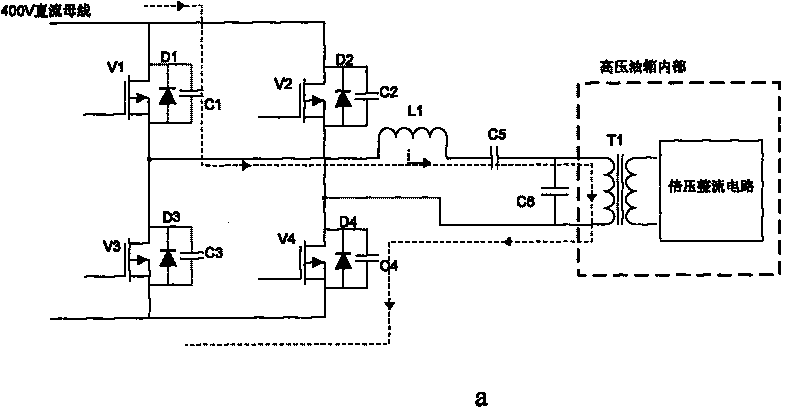

[0022] Such as figure 1 as shown, figure 1 It is a block diagram of the principle structure of the high-voltage generator of the X-ray machine of the present invention. The single-phase AC power is sent into the high-voltage generator through the input terminal of the high-voltage generator. After the input AC is rectified and filtered, soft-start unit 1 and power factor correction unit 2 (PFC), AC / DC conversion is realized, and the The DC bus voltage is pre-stabilized at 400V. The DC bus is divided into three routes, supplying the high voltage inverter 3, the filament inverter 6 and the control power supply 9 respectively. The output of the high-voltage inverter 3 is connected to the high-voltage booster circuit in the high-voltage fuel tank 4 to boost the voltage to the high voltage required by the X-ray tube. The output of the filament inverter 6 is connected to the filament conversion circuit in the high-pressure oil tank 4, and supplies power to the filament of the X-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com