Gymnasium chair seat and back and fabrication technology thereof

A technology for sports venues and manufacturing processes, applied in chairs, other seating furniture, applications, etc., can solve problems such as poor product strength, large product consumables, and difficulty in controlling the molding size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

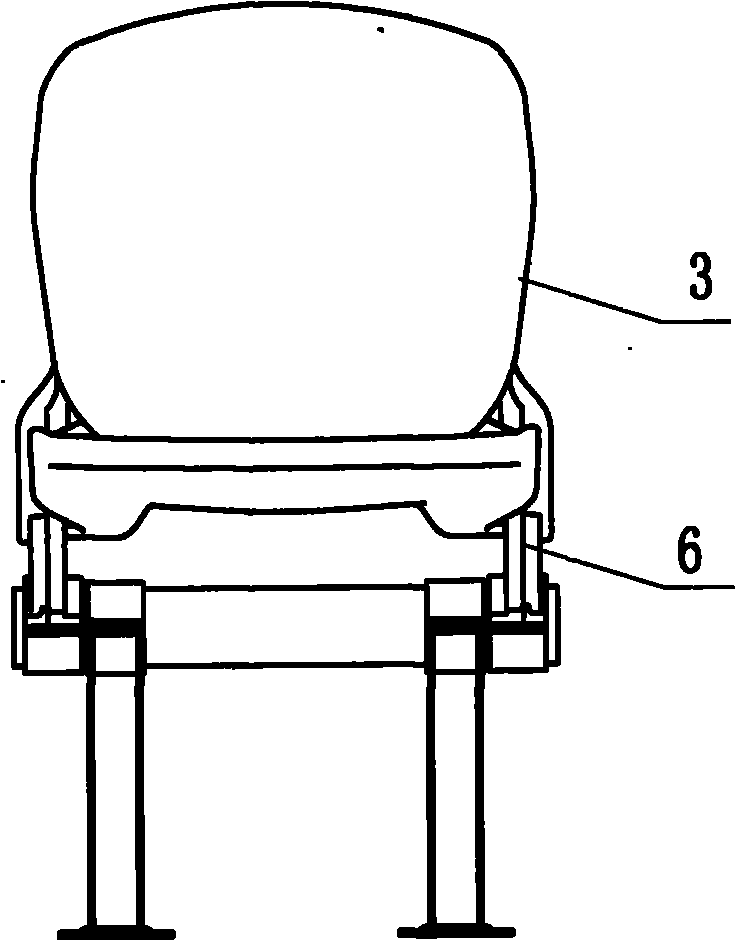

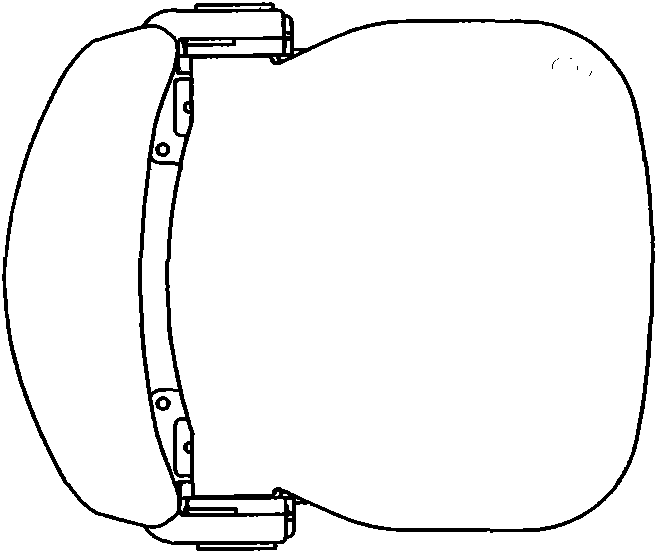

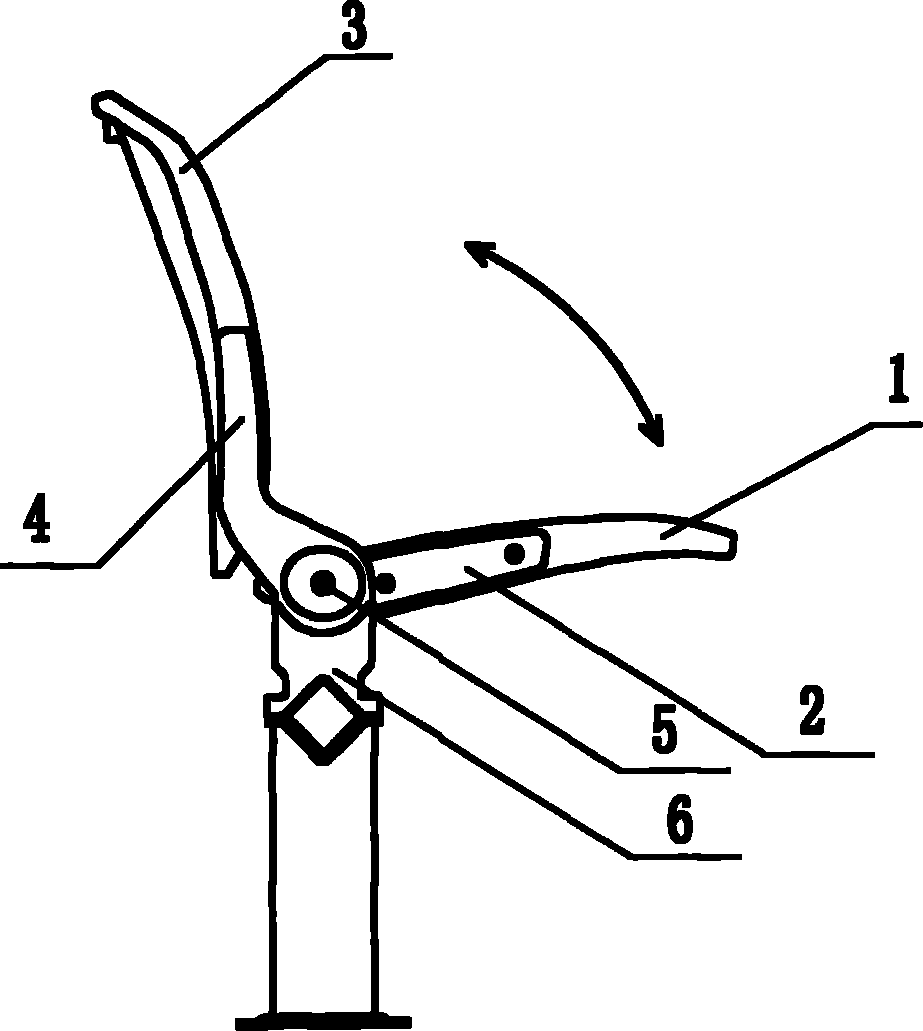

[0083] As shown in Fig. 1-Fig. 5 (D), a kind of public seat for stadiums includes a seat base 1, a seat support 2, a chair back 3, a chair back support 4, a connecting shaft 5 and a bracket 6; the seat base 1 Including seat surface 11, seat support connecting portion 12, chair back 3 includes seat back 31, seat back supporting connecting portion 32; Connection, the seat support connecting portion 12 and the seat support 2 are fixedly connected, the seat support 2 and the connecting shaft 5 are movably connected, and the seat 1 can be turned up. The seat 1 also includes seat hollow reinforcing ribs 13 , and the seat back also includes seat back hollow reinforcing ribs 33 .

[0084] The seat hollow reinforcing rib 13 is in the shape of an elbow, at the front edge of the seat surface 11 and the front part of both sides of the seat surface 11, the edge of the seat surface 11 is aligned with the outer side of the seat hollow reinforcing rib 13, and the seat hollow reinforcing rib 1...

Embodiment 2

[0087] Such as Figure 6 , Figure 7 As shown, the seat air injection hole 133 is at the end of the seat hollow reinforcing rib 13 on the right side of the seat 1; the seat overflow port 134 is at the end of the seat hollow reinforcing rib 13 on the left side of the seat surface 11 . The chair back air injection hole 333 is at the end of the chair back hollow reinforcing rib 33 on the right side of the chair back 31 ; the chair back overflow opening 334 is at the end of the chair back hollow reinforcing rib 33 on the left side of the chair back 31 . Others are the same as embodiment 1.

Embodiment 3

[0089] Such as Figure 8 As shown, the rib 13 is on the inner side of the edge in the seat, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com