Trichlorosilane de-dusting device and de-dusting process

A dust removal equipment and technology of trichlorosilane, applied in the directions of halosilane, halide silicon compound, dispersed particle separation, etc., can solve the problems of high risk, manpower and material resources, unfavorable for continuous and stable operation of production, etc. The effect of blocking degree, improving safety and prolonging stable operation period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

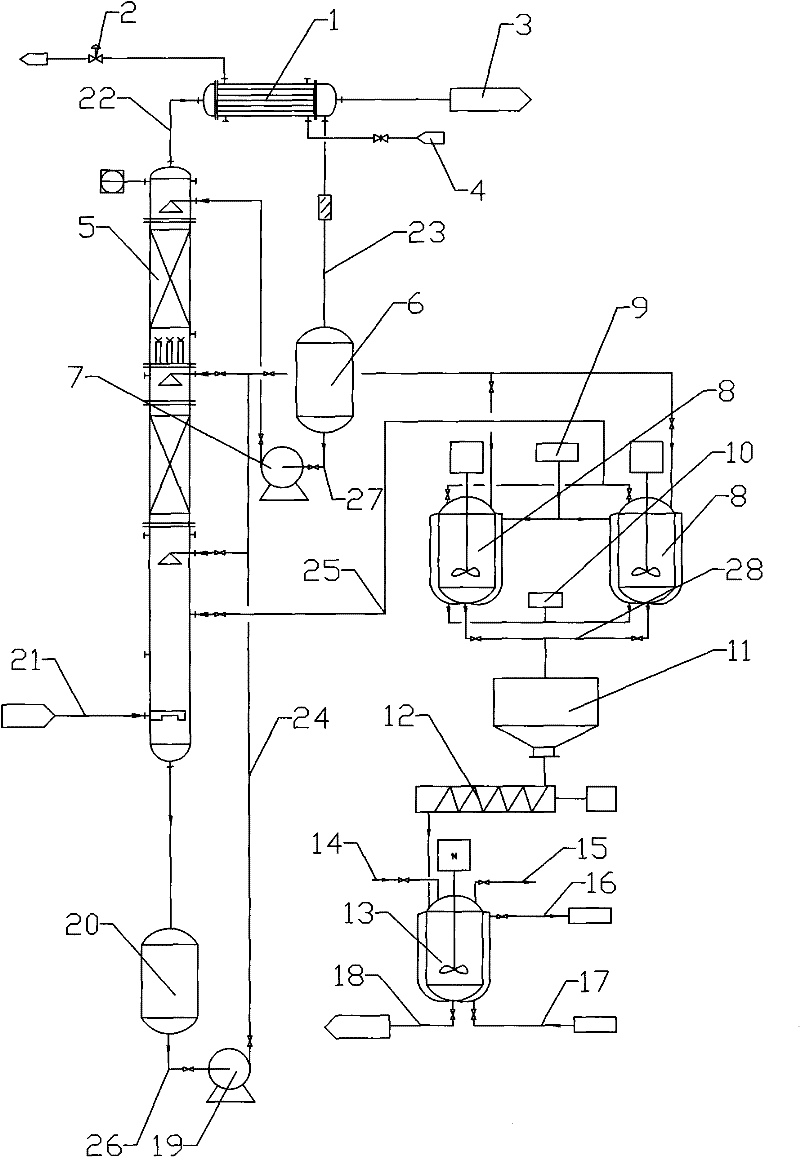

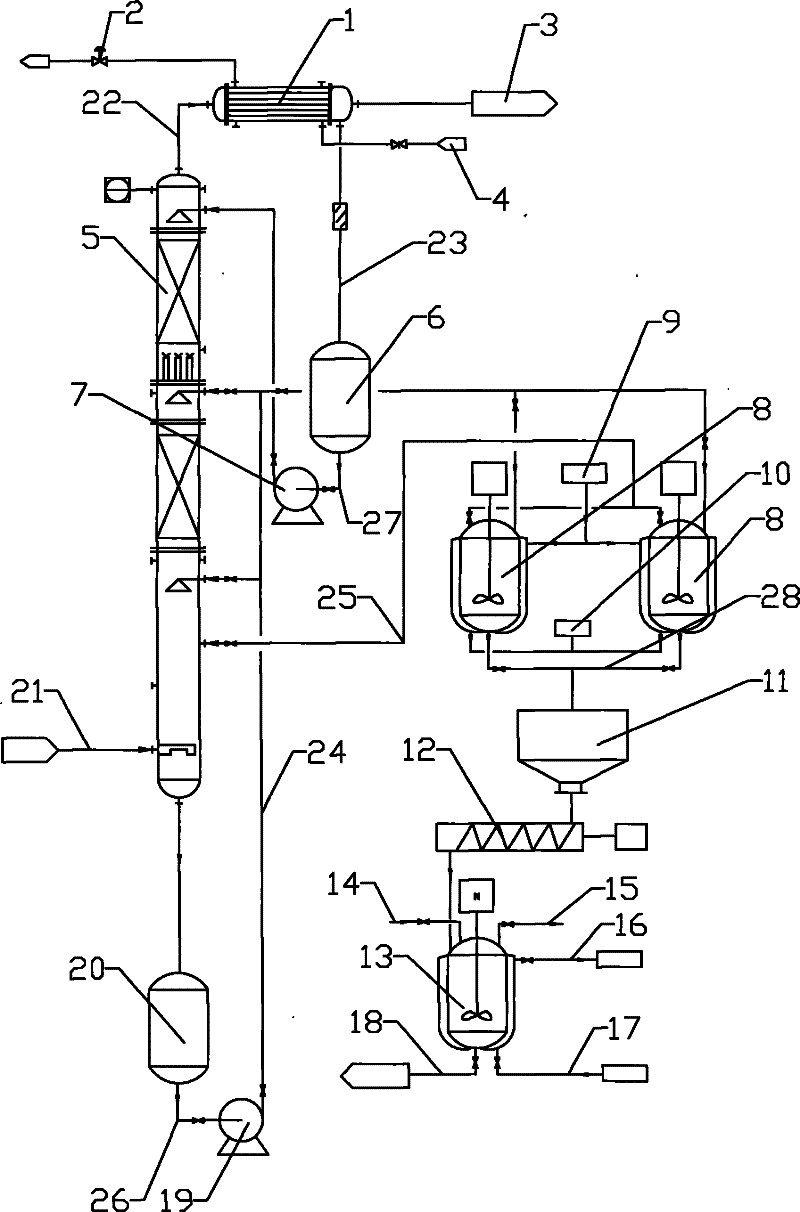

[0029] Embodiment, as shown in the figure, a kind of trichlorosilane dedusting equipment comprises dust washing tower 5, and the bottom of dust washing tower 5 is provided with synthesis gas inlet pipe 21, and the upper part is provided with synthesis gas outlet pipe 22, and described dust washing tower 5 is connected Silicon tetrachloride adding device is arranged, and silicon tetrachloride adding device comprises the first circulation liquid tank 20 that is connected with scrubbing tower 5 by pipeline, is provided with first circulation liquid outlet pipe 26 on the first circulation liquid tank 20, and this first The circulating liquid outlet pipe 26 is connected with the first circulation pump 19, the first circulation pump 19 is provided with a first circulation pump outlet pipe 24, and the first circulation pump outlet pipe 24 communicates with the upper part of the dust washing tower 5, and the synthesis gas outlet A synthetic gas cooling device is installed on the pipe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com