Cutting stress display device of full automatic inside diameter slicer with elastic feeding

A display device and inner circle slicing technology, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of low cutting speed, material damage, product concave center scrapping, etc., and avoid excessive force big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

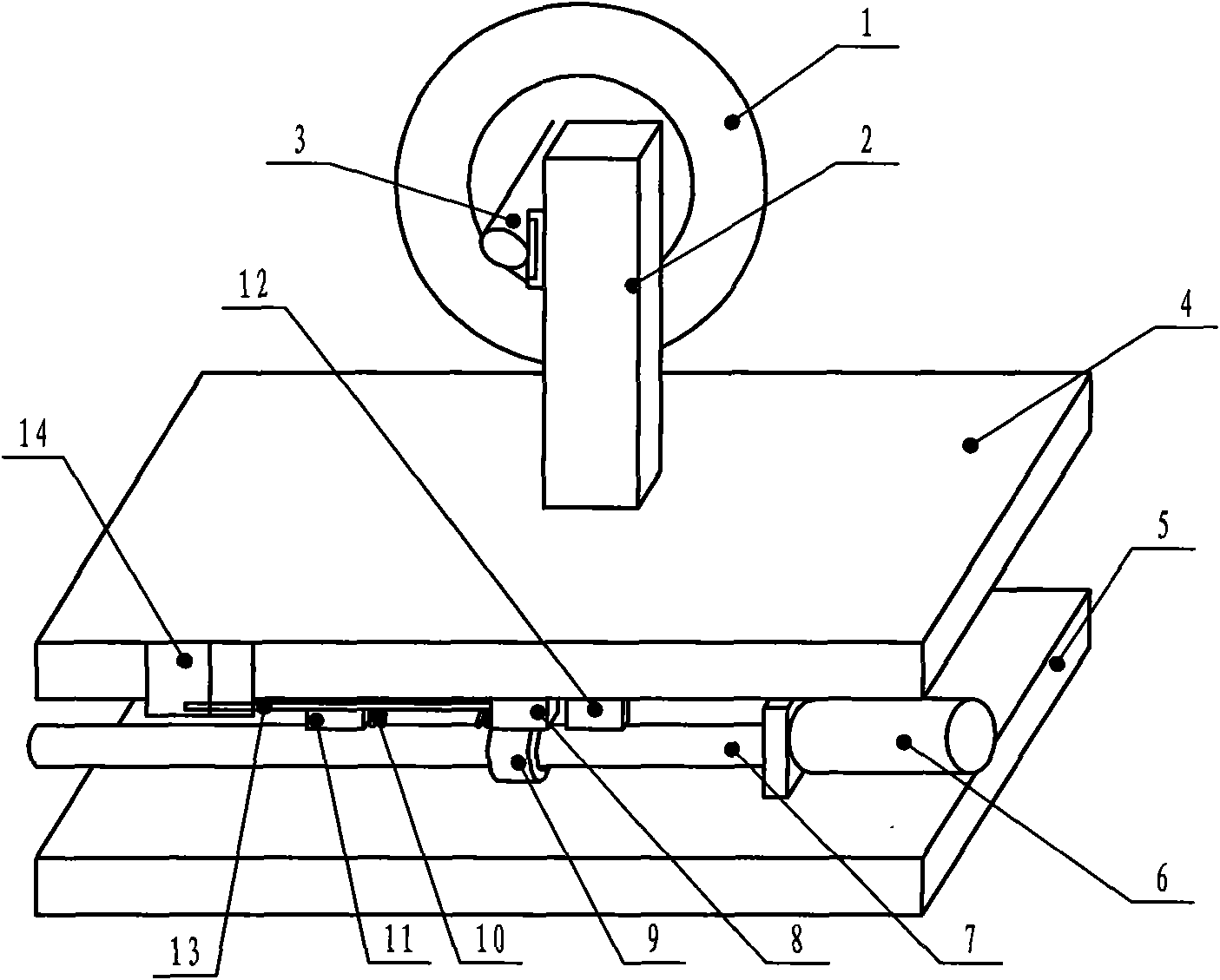

[0046] Example one: figure 1 As shown, this embodiment includes a cutting tool driven by a spindle motor 1, an X-axis moving table 4 driven by a stepping motor 6, and a Y-axis moving table 5 driven by a stepping motor. The X-axis moving table 4 is set on the Y axis. Above the mobile workbench 5, the X-axis mobile workbench 4 is provided with a clamping frame 2, and the displacement and force control transmission connection device between the X-axis mobile workbench 4 and the Y-axis mobile workbench 5 is provided with a spring 10 . The displacement and force control transmission connection device includes a stepping motor 6, a screw 7 is provided on the stepping motor 6, a screw nut 9 is sleeved on the screw 7, and the stepping motor 6 is fixedly installed on the Y axis to move and work On the table 5, the screw nut 9 is provided with a bearing block 8, one side of the bearing block 8 is connected with a spring 10, one end of the spring 10 is connected with the limiting block 11...

Embodiment 2

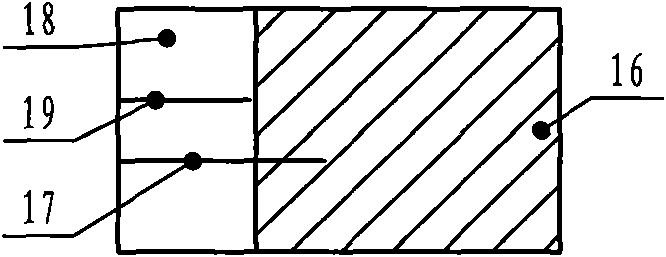

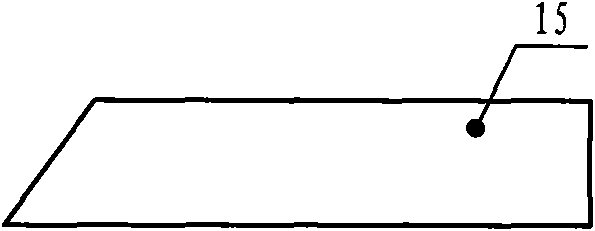

[0047] Embodiment two: figure 2 , image 3 As shown, the display window of this embodiment is provided with a transparent part 18, an opaque part 16, a limit working position line 19 and a normal working position line 17. The ruler 15 is a right-angle trapezoidal plate, and other structures are the same as the first embodiment.

Embodiment 3

[0048] Embodiment three: Figure 4 As shown, the display device is fixedly provided with a tension spring 30 on the X-axis moving table 4, one end of the tension spring 30 is fixed on the X-axis moving table, and the other end of the tension spring 30 is connected with an indicator needle plate 31 that can slide left and right. Connected, indexing marks are engraved on the indicating needle plate 31, the indicating needle plate 31 is covered by the display window 32, the indicating needle plate 31 is connected with the movable pulley 34, the movable pulley 34 is arranged on the pulley guide plate 35, and the movable pulley 34 is provided with an indicating needle plate Pull wire 33, one end of the indicator needle plate wire 33 is fixed on the X-axis moving table, the other end of the indicator needle plate wire 33 is connected to the indicator needle plate 31, one end of the displacement wire 36 is fixed on the screw nut assembly, and the displacement wire 36 The other end is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com