Numerical control machine tool main shaft structure

A technology of CNC machine tools and spindles, which is applied in the direction of metal processing machinery parts, large fixed members, maintenance and safety accessories, etc. It can solve the problems of burning spindle tools and affecting the processing accuracy, so as to avoid burning knives and improve processing safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the specific implementation process and implementation effect of the present invention, the following will be described in detail in conjunction with the accompanying drawings.

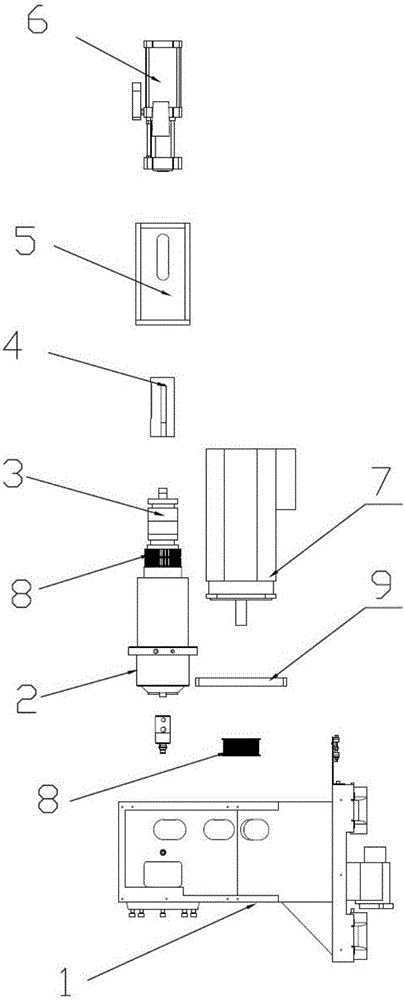

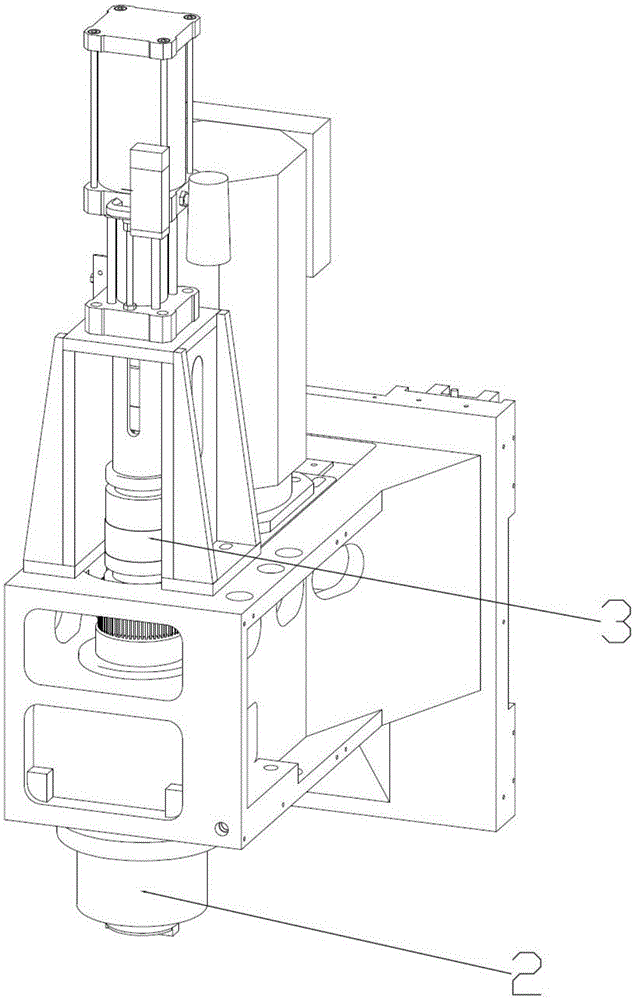

[0024] A CNC machine tool spindle structure, such as figure 1 , figure 2 and image 3 As shown, a spindle box 1 is included, and a spindle 2 is arranged on the spindle box 1, and the spindle 2 rotates relative to the spindle box 1 under the action of a motor.

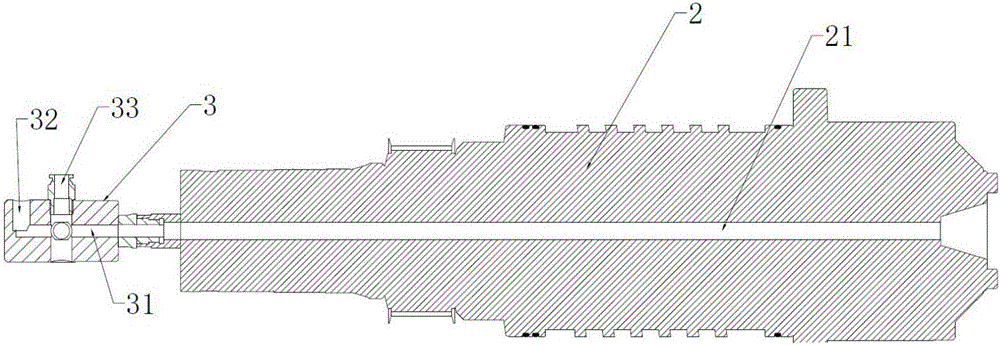

[0025] Such as figure 2 As shown, the upper end of the main shaft 2 is provided with a columnar liquid outlet head 3 and is fixedly connected to one end of the columnar liquid outlet head 3, the other end of the liquid outlet head 3 is connected to the knife assembly, the main shaft is connected to the gear 8, and the motor 7 is also connected to the gear 8, the gear 8 of the motor 7 is connected with the gear 8 of the main shaft 2 through the belt 9, the motor 7 drives the main shaft 2 to rotate throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com