Electro-fusion welding machine realizing welding quality monitoring through wireless network and implementation method

A wireless network and quality monitoring technology, applied in network topology, wireless communication, electrical components, etc., can solve the problems of easy loss, inability to realize welding joint positioning and storage management, and small amount of recorded data, and achieve the effect of saving human, material and financial resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described by examples below.

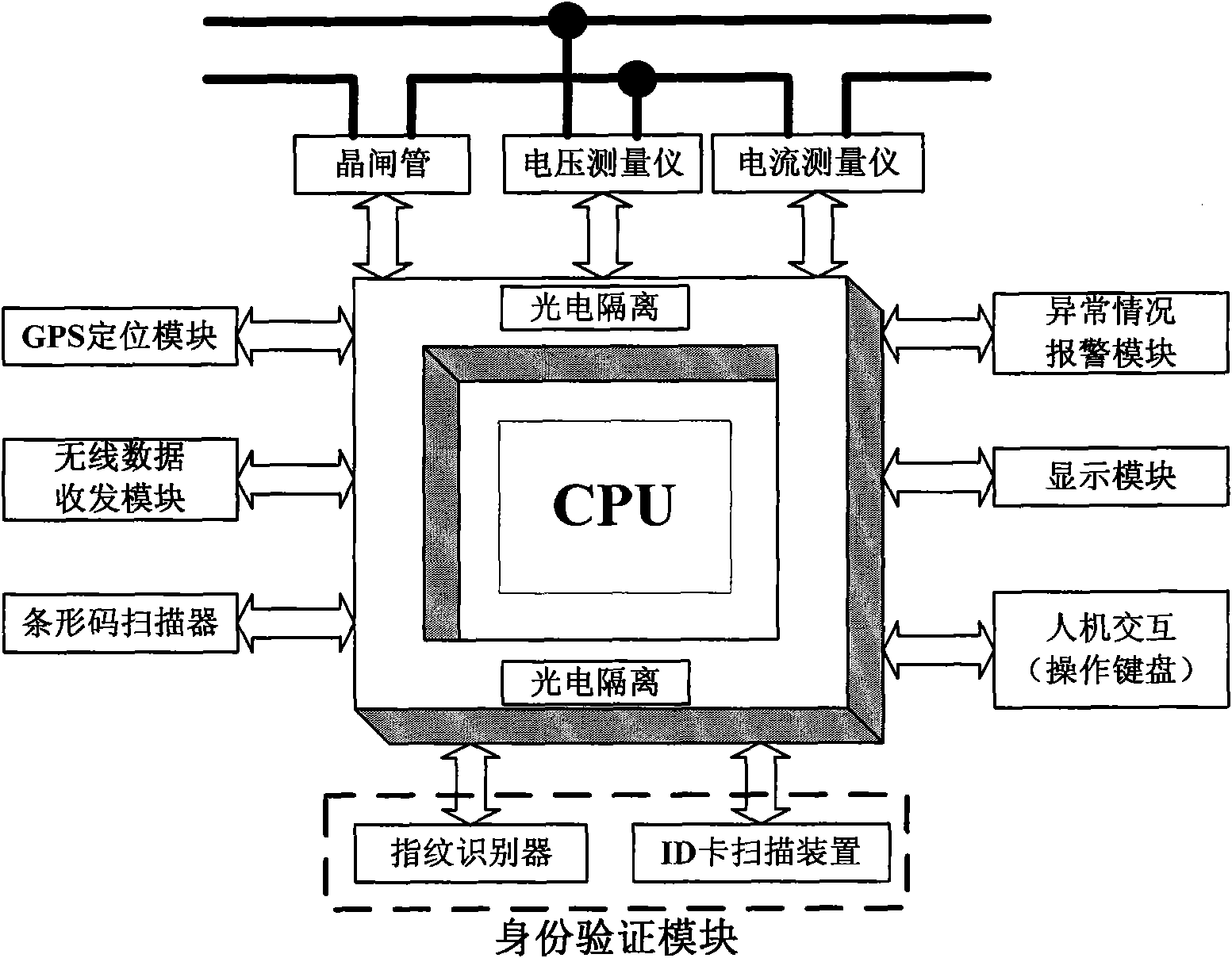

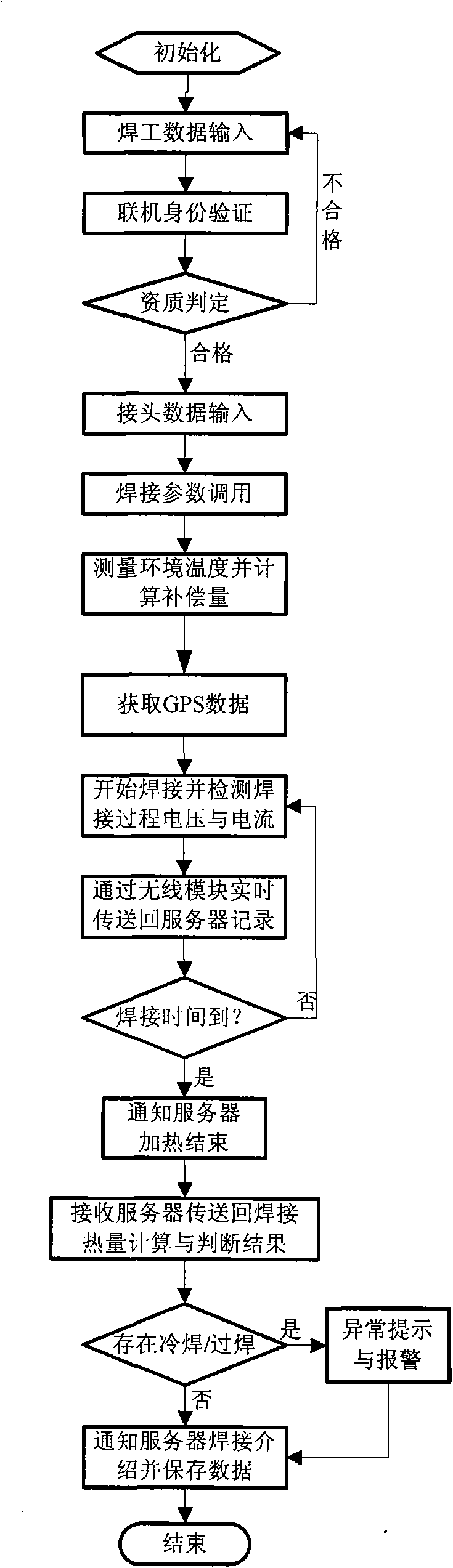

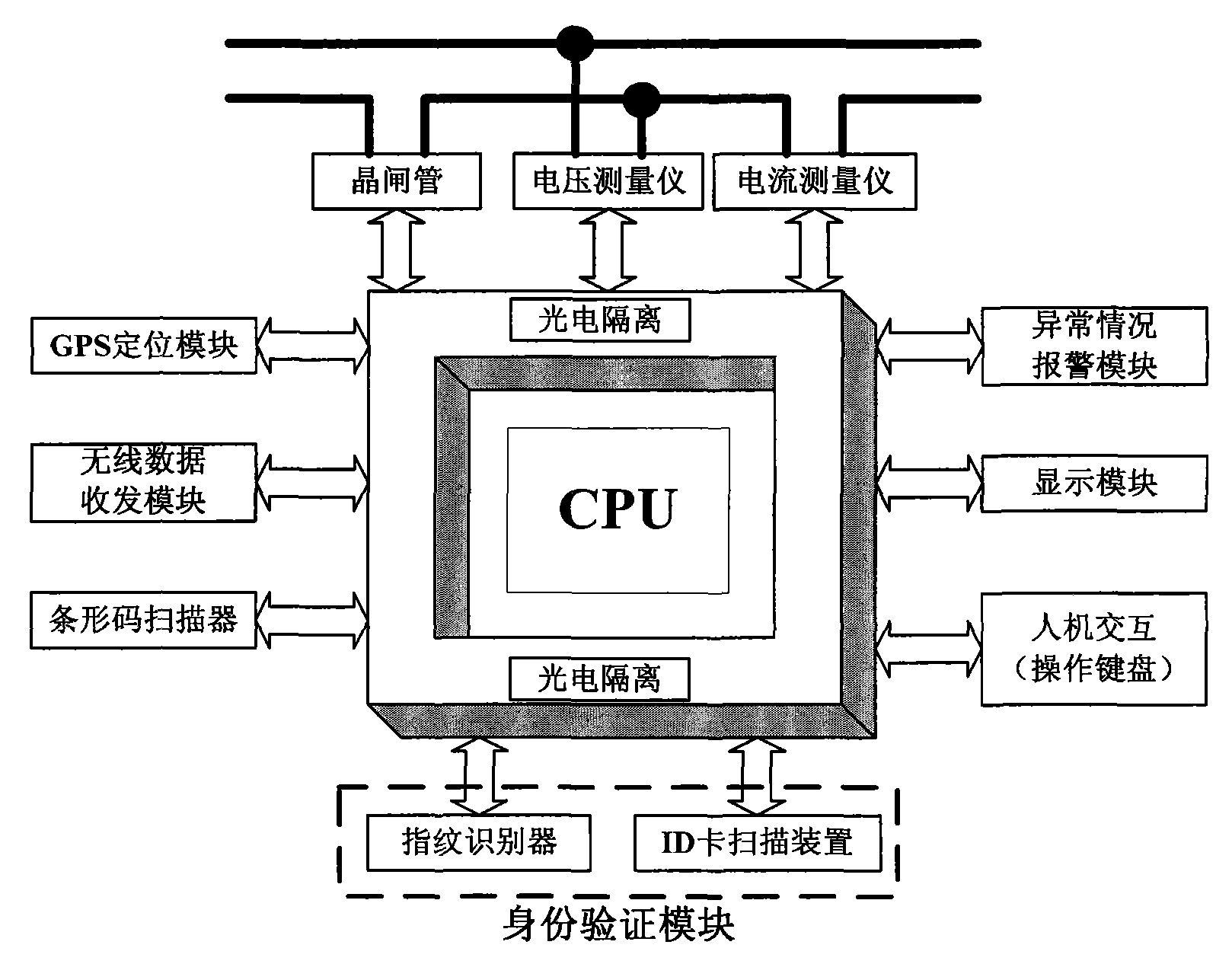

[0032] The electric fusion welding machine in the present invention includes a microprocessor connected to the main body of the electric fusion welding machine, and external equipment such as a display screen and an input keyboard usually provided by the electric fusion welding machine. Different from the existing welding machine, the electric fusion welding machine in the present invention also includes a microprocessor connected to the main body of the electric fusion welding machine, and the microprocessor is respectively connected to the identity verification module, the abnormal situation alarm module and the wireless data sending and receiving module. modules, and each module is connected to the power supply; according to the usual practice, the microprocessor and each module are connected through a photoelectric isolation module to ensure that the microprocessor is not disturbed during the operation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com