Preparation method of high polymeric polyalumnium sulfa coagulant for strengthening coagulation of drinking water

A technology of polysulfide aluminum chloride and coagulant, which is applied in the direction of aluminum sulfur compound, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of increasing the operation cost of water treatment, increasing the amount of sludge and water treatment agent residue, etc., to achieve Good application prospects, improved coagulation efficiency, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

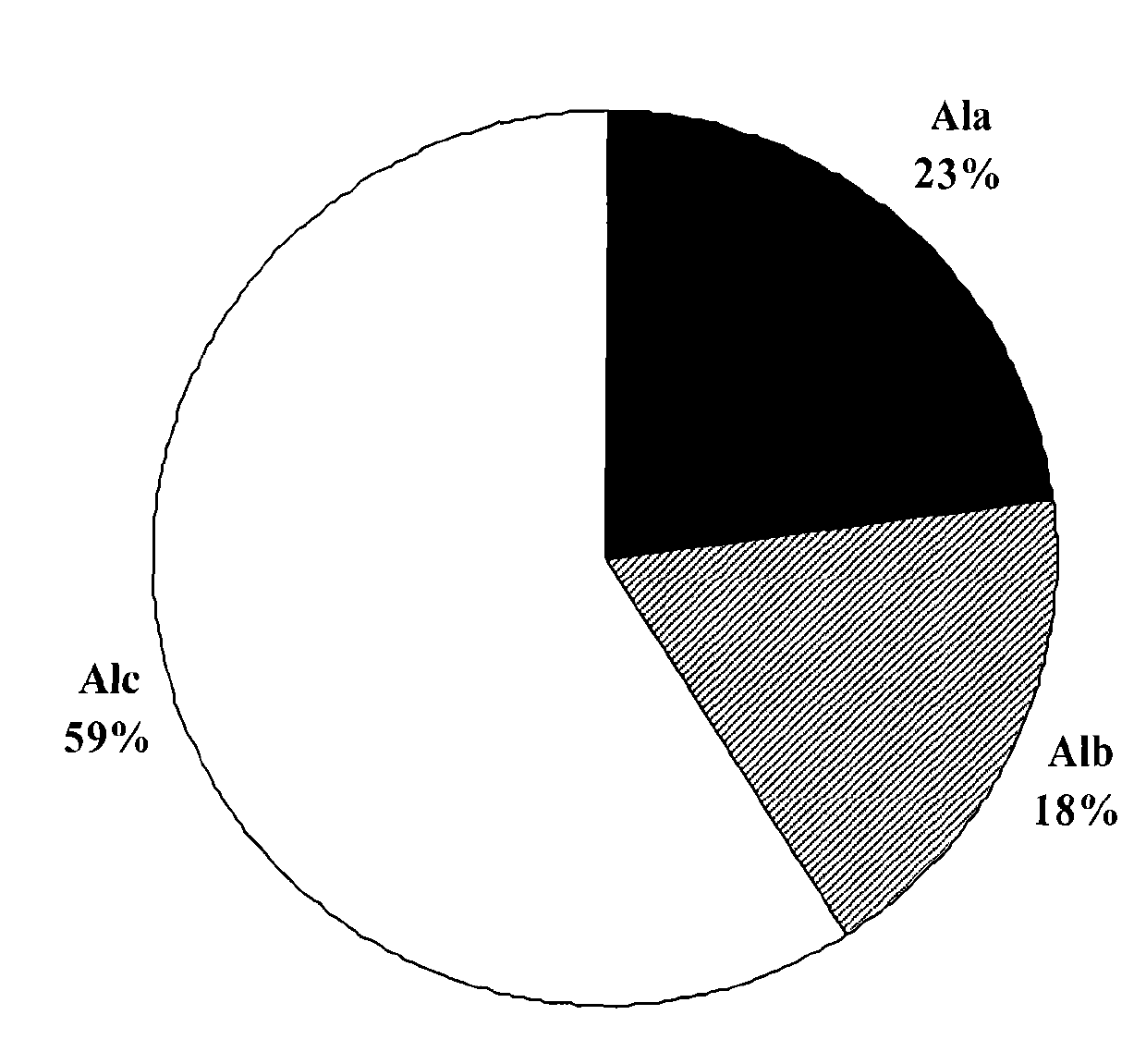

[0015] Preparation of high polysulfide aluminum chloride coagulant: first AlCl 3 ·6H 2 O prepared into 0.4mol / L AlCl 3 solution, by SO 4 2- / Al 3+ Molar ratio 0.06 to AlCl 3 Add Na to the solution 2 SO 4 solid, and stirred to Na 2 SO 4 completely dissolved. Under the conditions of normal temperature, normal pressure and vigorous stirring, 0.4mol / L Na 2 CO 3 solution and containing Na 2 SO 4 0.4mol / L AlCl 3 The solution mixes quickly and controls the OH - / Al 3+ The molar ratio is 2.0, and the total aluminum concentration is 0.2 mol / L. Stir at a speed of 200r / min until the solution becomes a stable and transparent homogeneous solution. The obtained homogeneous solution was heated at a constant temperature of 95° C., stirred, and refluxed for 8 hours, and the stirring intensity was controlled to be 200 r / min. After natural cooling and aging at room temperature for 5 days, a high polysulfide aluminum chloride coagulant was obtained. The speciation distribution ...

Embodiment 2

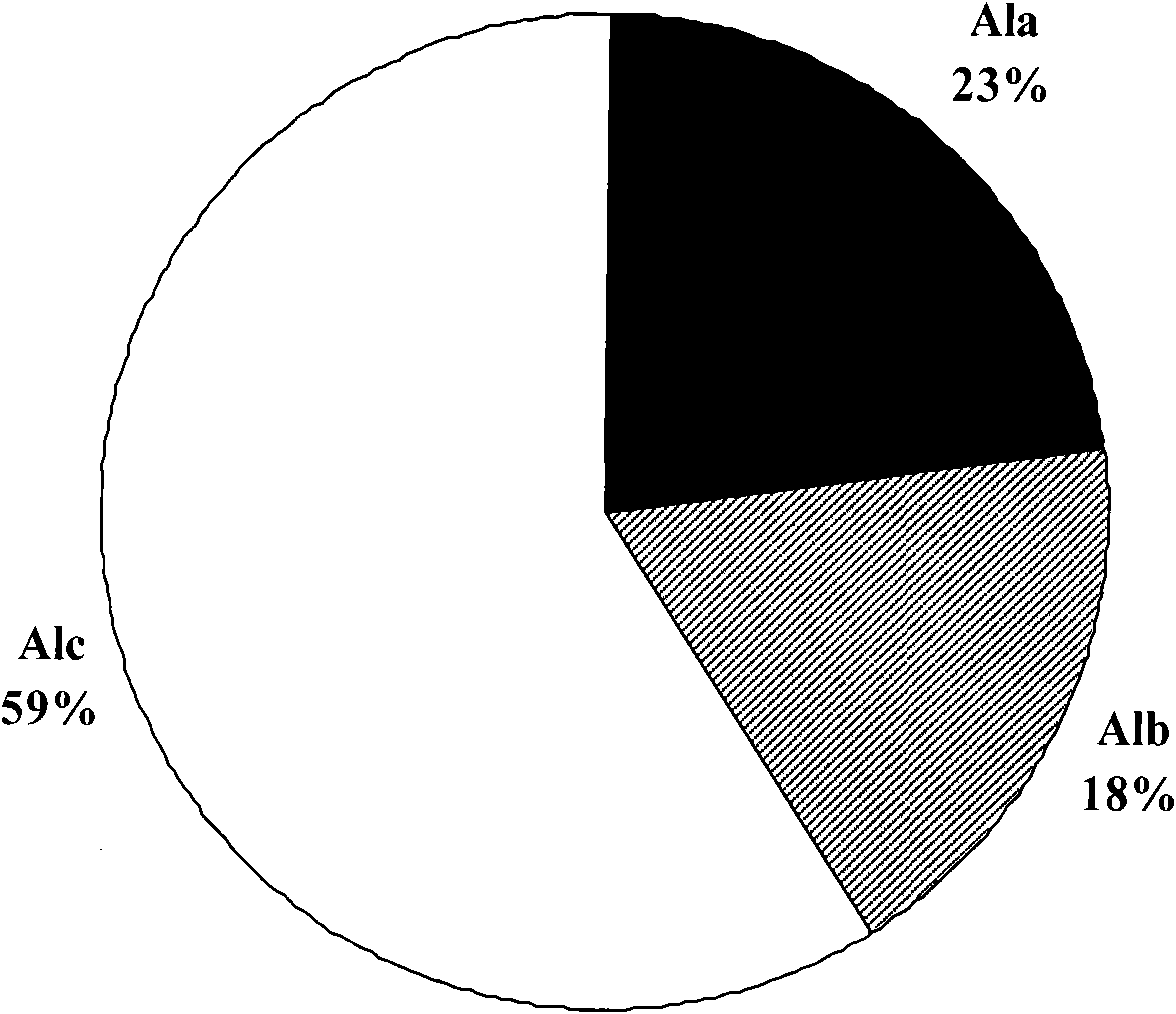

[0021] Preparation of high polysulfide aluminum chloride coagulant: the difference between this embodiment and embodiment 1 is OH - / Al 3+ The molar ratio is controlled at 1.6, SO 4 2- / Al 3+ The molar ratio is controlled at 0.08, and other steps and parameters are the same as in Example 1.

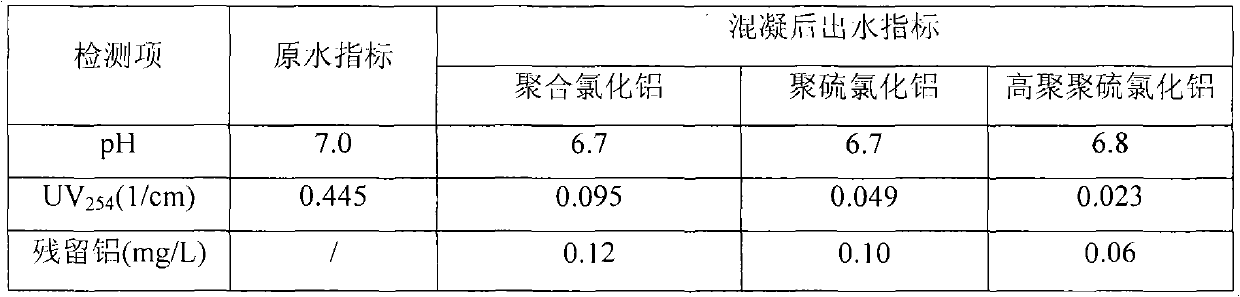

[0022] Coagulant application: The high polysulfide aluminum chloride coagulant prepared by the above method is used to treat the high turbidity influent raw water of a waterworks in the south. The pH is not adjusted during the treatment process, and 0.1mmol / L high polysulfide aluminum chloride (with Al), first stirred rapidly at 200r / min for 2min, then stirred slowly at 30r / min for 15min, allowed to settle for 30min, and then took the supernatant for testing. Natural organic matter is measured by UV absorbance at 254nm 254 Said, DOC and turbidity were measured by Continental 1010 total carbon analyzer and WTW company Turb550 turbidity meter respectively, and the residual aluminum con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com