Novel amination process of amino silane

A technology of aminosilane amine and new process, which is applied in the field of new process of aminosilane amination, can solve the problems of low reaction efficiency, complex reaction device, high equipment investment, etc., and achieve the effect of stable operation, high yield and reasonable and compact device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

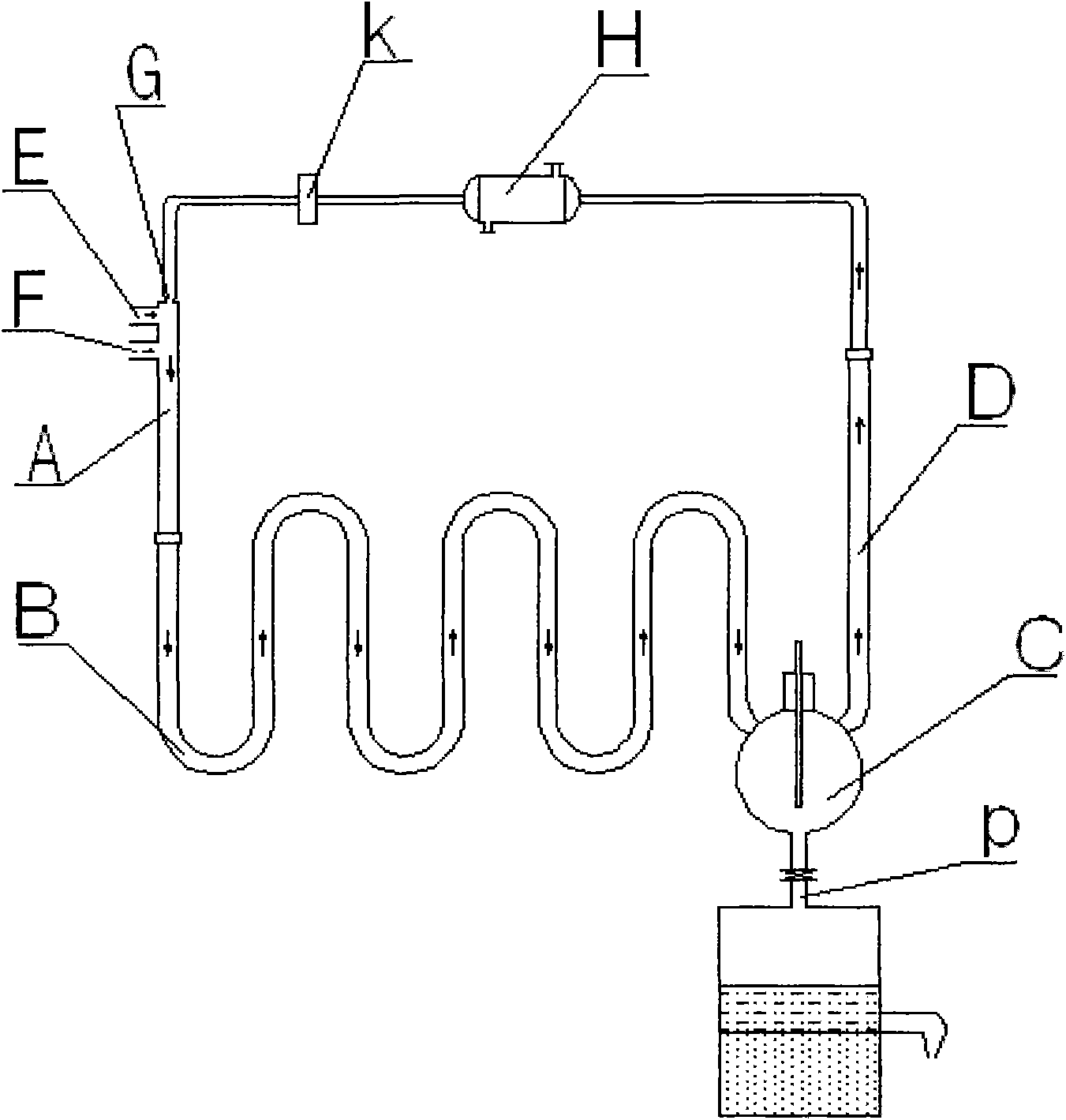

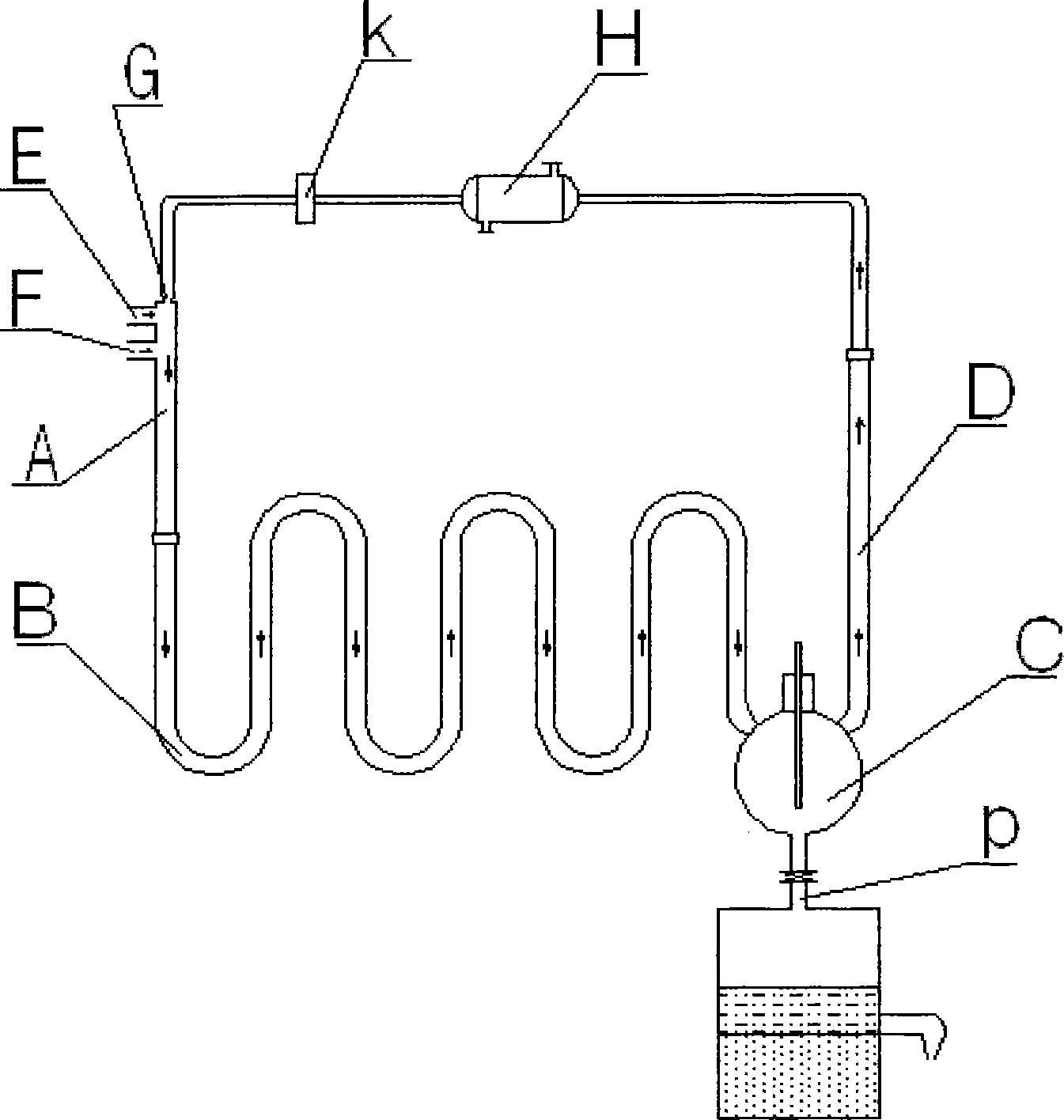

[0016] Embodiment 1, the new process of aminosilane amination, wherein: the bottom of the reaction tower A communicates with the inlet of the serpentine tube B, the outlet of the serpentine tube B communicates with the upper feed port of the product receiving device C, and the outlet of the product receiving device C The bottom is provided with a discharge port P, and the top of the product receiving device C is also communicated with the bottom end of the gas riser D, and the upper end of the gas riser D passes through the pipeline, the condenser H, the pipeline, and the reflux feeding port G communicates with the top of the reaction tower A; The upper part of the reaction tower A is provided with a first feeding port E and a second feeding port F in turn;

[0017] Its technological process: put 1530-2000g of ethylenediamine in the product receiving device C in advance, raise the temperature to make the ethylenediamine boil and vaporize, and evenly add γ -Chloropropylmethyldi...

Embodiment 2

[0021] Embodiment 2, the new process of aminosilane amination, wherein: the packing layer in the reaction tower A is 1-1.2 meters, the material is glass or ceramic material, and the porosity in the packing layer is 60-70%. All the other are with embodiment 1.

Embodiment 3

[0022] Embodiment 3, a new aminosilane amination process, wherein: the number of units of the serpentine tube B is 2-6, and its total length is 1-1.5 meters. All the other are the same as embodiment 1 and embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com