Water-solubility plasticine composition and preparation method thereof

A manufacturing method and technology of the composition, applied to the water-soluble plasticine composition and the field of manufacture thereof, can solve the problems of high cost, difficult to obtain polyoxyethylene, and achieve the effects of low cost, light weight and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

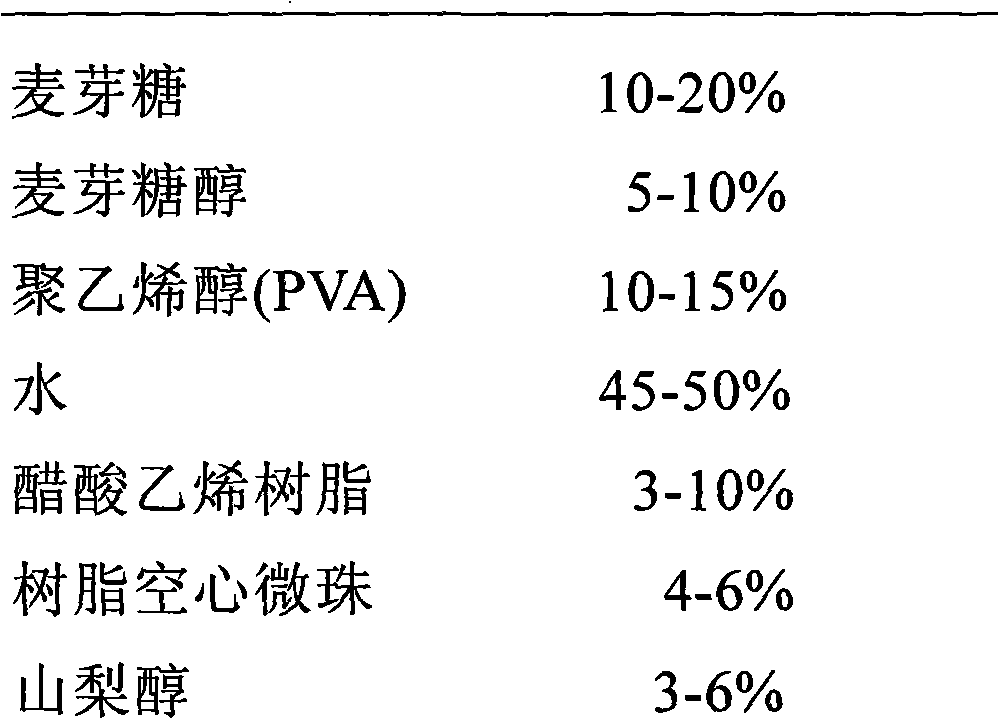

[0018] The composition components of an embodiment of the water-soluble plasticine composition provided by the present invention are described in detail below. This embodiment is mainly composed of polyvinyl alcohol (Polyvinyl Alcohol, PVA), vinyl acetate resin, water, maltose, maltitol, and hollow microspheres with a particle size of 5-100 μm.

[0019] When specifically implemented, the PVA may be partially hydrolyzed polyvinyl acetate. The role of PVA is to bind the filling so that the statue can be well formed. The thermal stability and elongation ability of PVA increase with the increase of its molecular weight. However, if its molecular weight is too large, the molding ability of clay will be reduced, thus increasing the difficulty of molding. PVA should be first prepared into a paste, preferably, the corresponding amount of PVA and water are heated at a temperature of 85-95°C for about half an hour to form a 20%-25% paste.

[0020] The vinyl acetate resin can be ethyle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com