Method for preparing exorphins from soybean protein isolate by fractional hydrolysis

A technology of soybean protein isolate and step-by-step hydrolysis is applied in the field of preparation of exorphins, which can solve the problems of high cost and easy generation of harmful substances, and achieve the effects of low price, simple preparation method and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Specific Embodiment 1: In this embodiment, the method for preparing exorphins by hydrolyzing soybean protein isolate step by step is carried out according to the following steps: 1. Put soybean protein isolate into pepsin for hydrolysis, the hydrolysis temperature is 36~38°C, and the pH is 1.8 ~2.2, the hydrolysis time is 2~6h, and the dosage of pepsin per gram of soybean protein isolate is 3500~4500U; 2. Put it into trypsin, acid protease, alkaline protease or neutral protease after pepsin hydrolysis Hydrolysis, the hydrolysis time is 2~6h, that is, exorphins are obtained.

[0014] The soybean protein isolate in step 1 of this embodiment is food grade (moisture 6.7182%, protein (dry basis) 82.6052%), and can be purchased from Harbin Gaoke Soybean Food Co., Ltd.

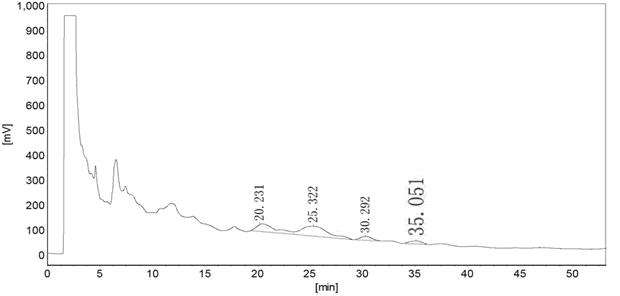

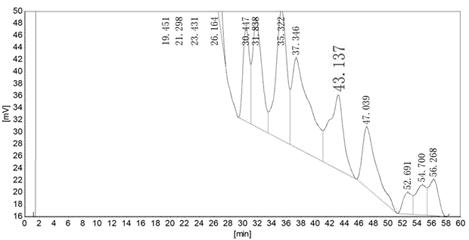

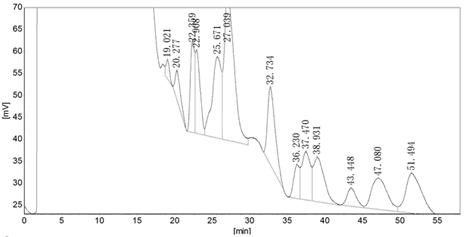

[0015] The exorphin prepared in this embodiment is tested by high-performance liquid chromatography, and the detection conditions are: C18 chromatographic column, wavelength 220nm, column temperature 25°C, inj...

specific Embodiment approach 2

[0018] Embodiment 2: This embodiment differs from Embodiment 1 in that the hydrolysis temperature in step 1 is 37° C., the pH is 2, the hydrolysis time is 5 hours, and the amount of pepsin per gram of soybean protein isolate is 4000 U. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0019]Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the conditions of trypsin hydrolysis in step two are: the hydrolysis temperature is 58~62°C, the pH is 7.5~8.5, and in every gram of soybean protein isolate The dosage of trypsin is 7000~9000U; the acid protease hydrolysis condition is: hydrolysis temperature is 42~48℃, pH is 2.5~3.5, the dosage of acid protease in each gram of soybean protein isolate is 5000~7000U; the alkaline protease hydrolysis condition is : The hydrolysis temperature is 51~57℃, the pH is 7.5~8.5, the amount of alkaline protease per gram of soybean protein isolate is 5000~7000U; the hydrolysis conditions of neutral protease are: the hydrolysis temperature is 52~58℃, the pH is 6.5~ 7.5, the dosage of neutral protease per gram of soybean protein isolate is 5000~7000U. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com