A kind of al2o3/tial intermetallic compound composite material and preparation method thereof

An intermetallic compound and composite material technology, which is applied in the field of Al2O3/TiAl intermetallic compound composite material and its preparation, can solve the problems of reducing material properties, uniform distribution of disperse phase in matrix materials, etc. Temperature and hot pressing pressure, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

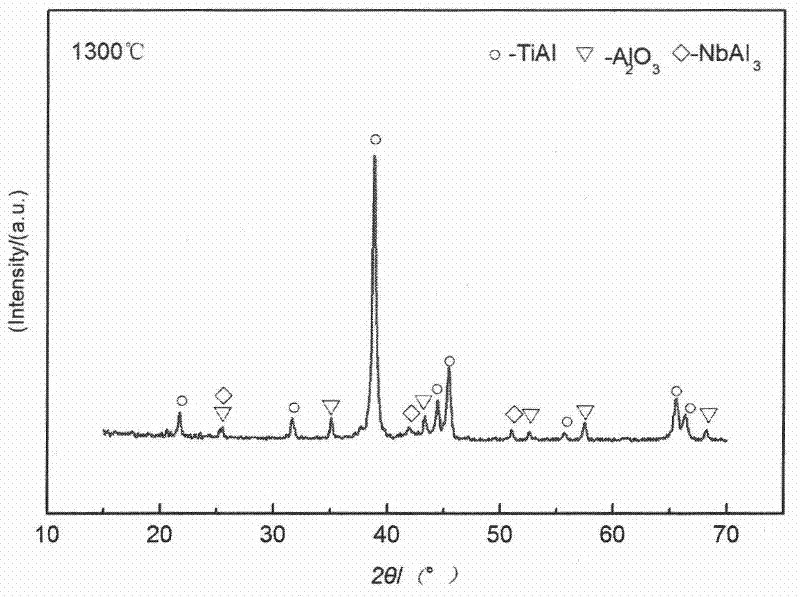

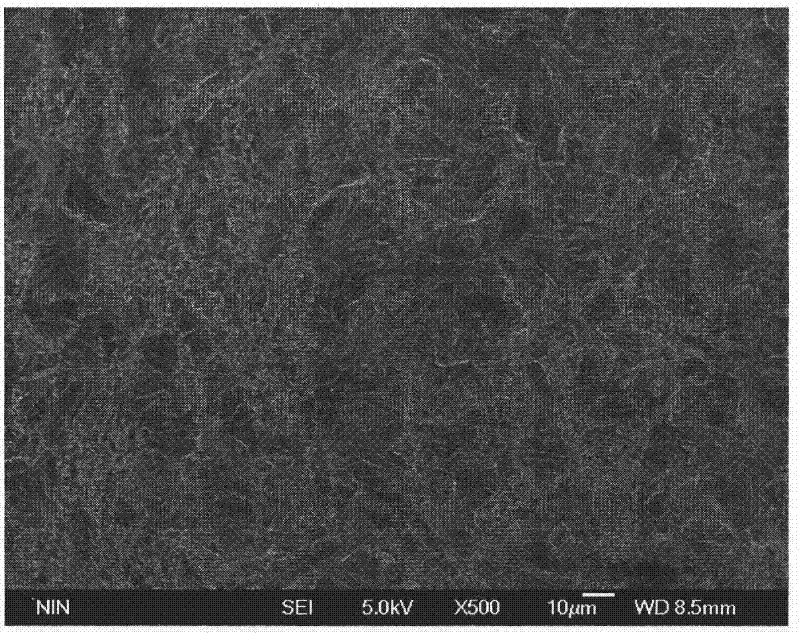

Image

Examples

Embodiment 1

[0020] The Al to be prepared in this embodiment 2 o 3 / TiAl compound composite material, it is characterized in that, raw material composition weight percentage is that Ti powder accounts for 51.07% of total weight, Al powder accounts for 30.57%, Cr 2 o 3 Powder accounted for 2.94% and Nb 2 o 5 Powder accounted for 15.42%.

[0021] The preparation process steps of the present embodiment are:

[0022] (1) The purity is greater than 99%, and the fineness is less than 200 mesh metal Ti powder, Al powder, Nb 2 o 5 Powder and Cr 2 o 3 Powder, Ti powder accounts for 51.07% of the total weight, Al powder accounts for 30.57%, Cr 2 o 3 Powder accounted for 2.94% and Nb 2 o 5 Powder accounts for 15.42% to make a mixture;

[0023] (2) Add the mixture obtained in step (1) into a high-alumina ball mill tank and add absolute ethanol with a mass of 50% of the mixture as a medium to mix and grind for 60 minutes at a speed of 700 rpm, and pass through a 200-mesh sieve;

[0024] (...

Embodiment 2

[0030] The Al to be prepared in this embodiment 2 o 3 / TiAl compound composite material, it is characterized in that, raw material composition weight percent is that Ti powder accounts for 75.29% of total weight, Al powder 22.85%, Cr 2 o 3 Powder 0.3% and Nb 2 o 5 Powder 1.56%.

[0031] The preparation process steps of the present invention are:

[0032] (1) The purity is greater than 99%, and the fineness is less than 200 mesh metal Ti powder, Al powder, Nb 2 o 5Powder and Cr 2 o 3 Powder, Ti powder accounts for 75.29% of the total weight, Al powder 22.85%, Cr 2 o 3 Powder 0.3% and Nb 2 o 5 The proportion of powder 1.56% is made into mixture;

[0033] (2) Add the mixture obtained in step (1) into a high-alumina ball mill tank and add 100% absolute ethanol as a medium to mix and grind at a speed of 800 rpm for 30 minutes, and pass through a 200-mesh sieve;

[0034] (3) Put the powder obtained by sieving in step (2) into a graphite grinding tool, and heat press an...

Embodiment 3

[0038] The Al to be prepared in this embodiment 2 o 3 / TiAl compound composite material, it is characterized in that, raw material composition weight percent is that Ti powder accounts for 65.37%, Al powder accounts for 26.01%, Cr 2 o 3 Powder accounted for 1.38% and Nb 2 o 5 Powder accounted for 7.24%.

[0039] The preparation process steps of the present embodiment are:

[0040] (1) The purity is greater than 99%, and the fineness is less than 200 mesh metal Ti powder, Al powder, Nb 2 o 5 Powder and Cr 2 o 3 Powder, Ti powder accounts for 65.37% of the total weight, Al powder accounts for 26.01%, Cr 2 o 3 Powder accounted for 1.38% and Nb 2 o 5 Powder accounts for 7.24% to make a mixture;

[0041] (2) Add the mixture obtained in step (1) into a high-alumina ball mill tank, and add anhydrous ethanol with a mixture mass of 80% as a medium to mix and grind at a speed of 700 rpm for 50 minutes, and pass through a 200-mesh sieve;

[0042] (3) Put the powder obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com