Method for constructing quake-proof masonry house by utilizing prefabricated constructional column ring beams

A technology for constructing columns and houses, which is applied in the direction of building construction, earthquake resistance, construction, etc., can solve the problems of increased labor intensity of construction workers, lack of anti-seismic measures, and prolonging the construction period of houses, etc., to achieve good earthquake resistance, fast speed, The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

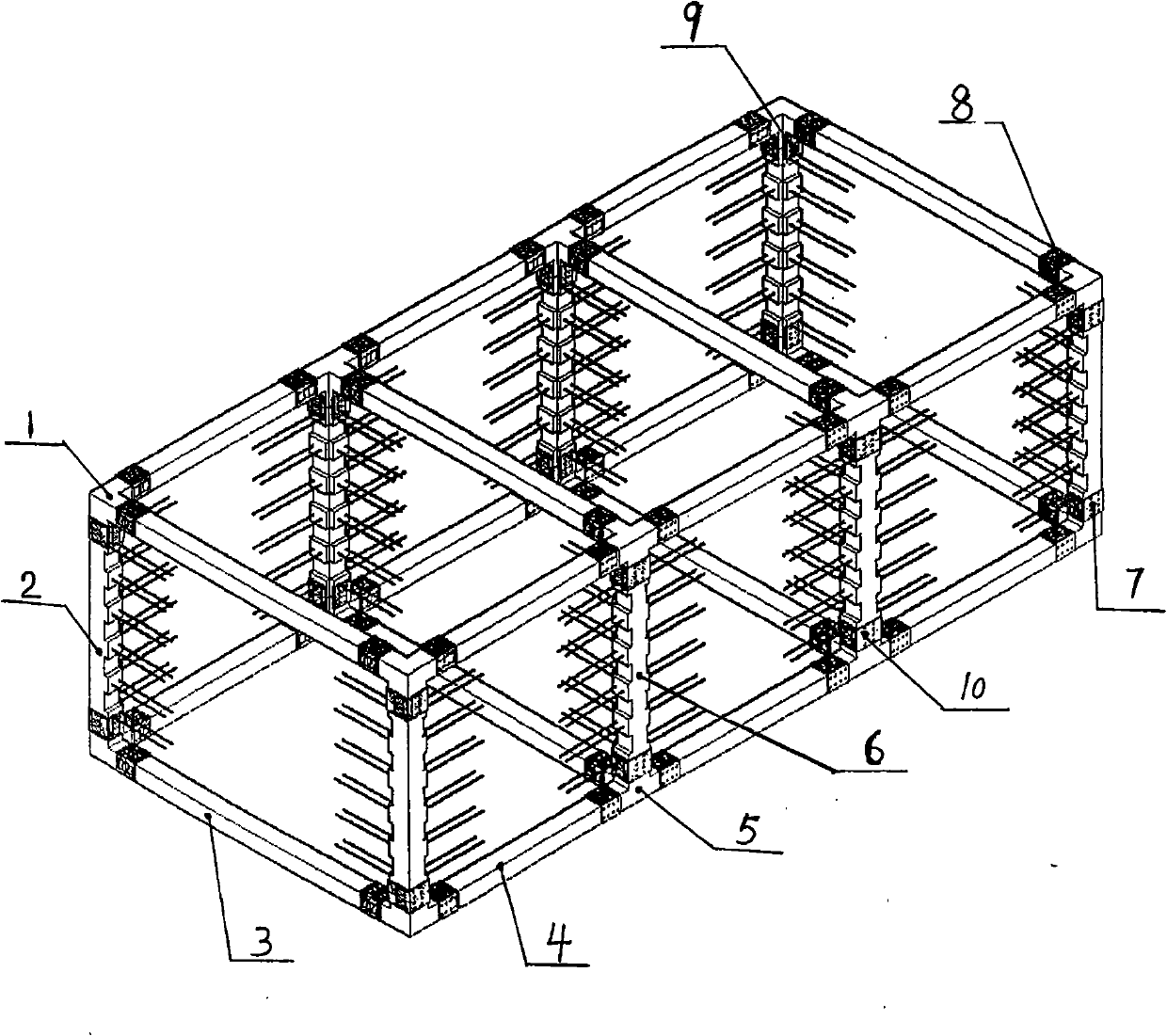

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings.

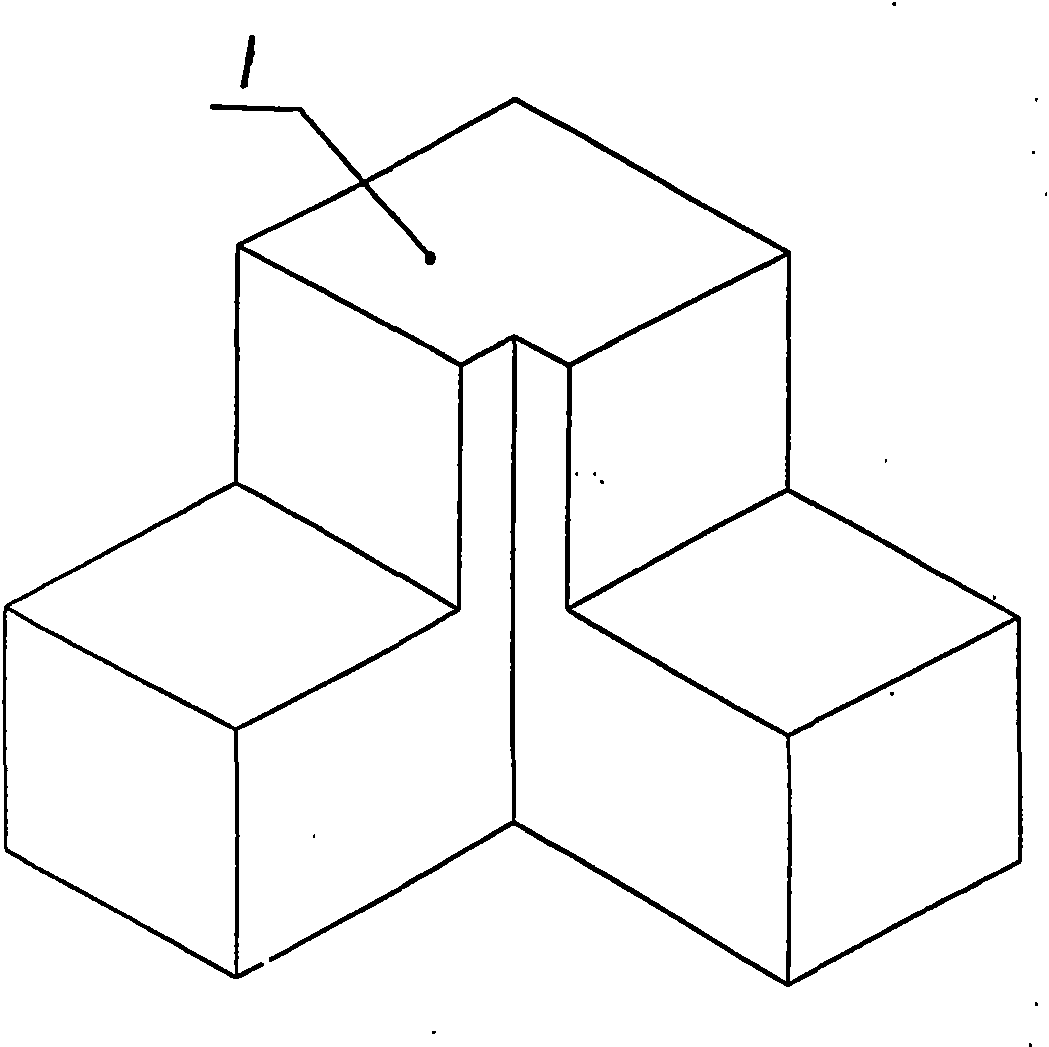

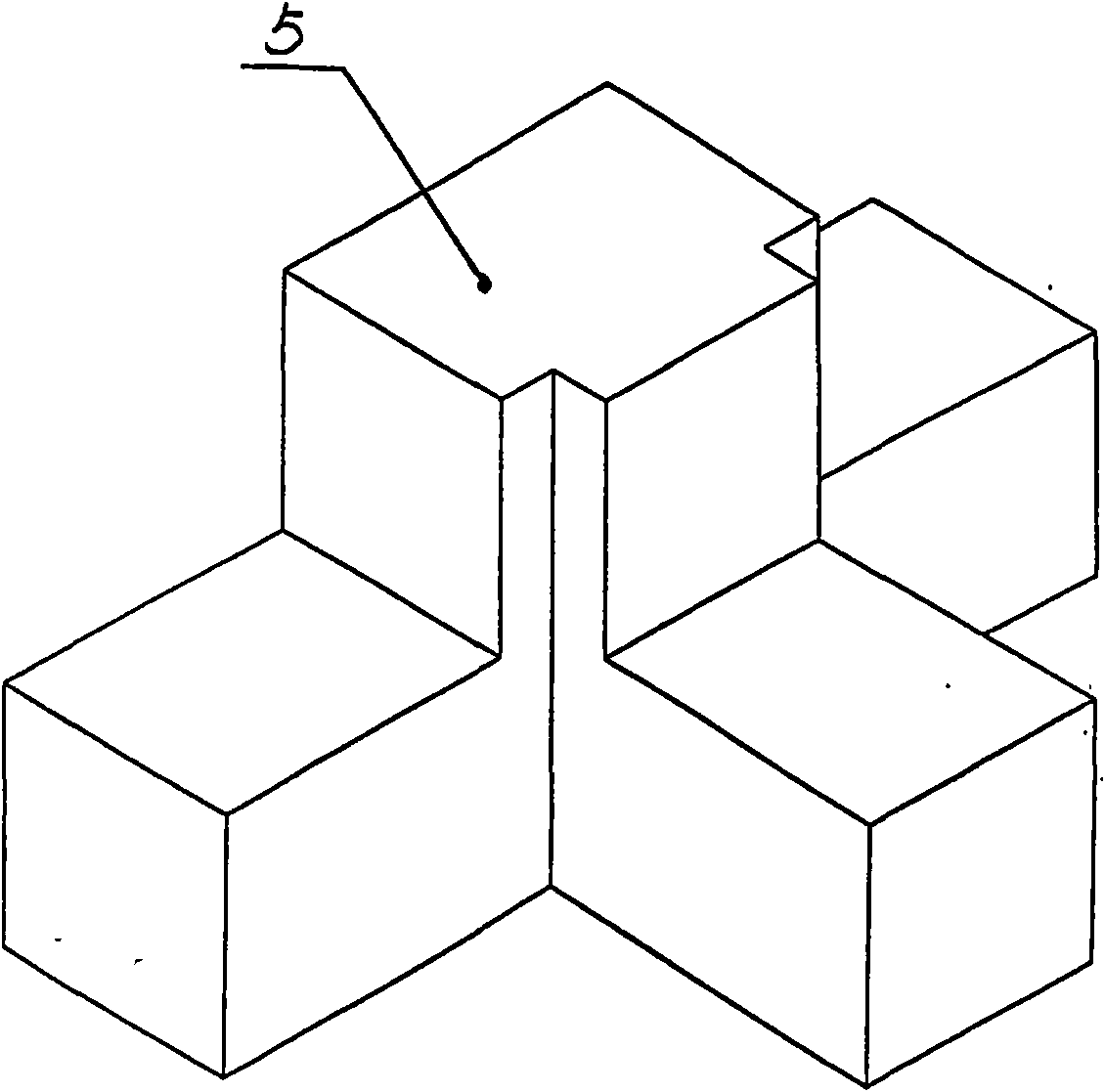

[0049] like figure 1 , 2, 3, 4, 5, 6, 7, 8, 9, and 10, the connector 7 is a welded composite steel plate with a cross-sectional shape of "L" shape, and round holes are arranged on both faces, and each face The number of round holes set is eight, and the connecting piece 8 and the connecting piece 10 are all welded composite steel plates with a cross-sectional shape of "U" shape, and round holes are arranged on three faces, and the number of round holes set on each face They are all eight, and the connecting piece 9 is a steel plate with a cross-sectional shape of "one", and eight round holes are set on the steel plate, and the adjacent two cylindrical surfaces of the side column 2 are horse-shaped and are provided with tie bars 11, The three adjacent cylinder surfaces of the central column 6 are prefabricated into a horse-toothed shape, and two symmetrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com