Dust hood for drilling machine

A technology for dust hoods and drilling rigs, applied in the field of dust hoods, can solve the problems of operators suffering from pneumoconiosis, polluting the environment, and machine wear, and achieve the effects of protecting operators and machines, preventing dust from flying, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

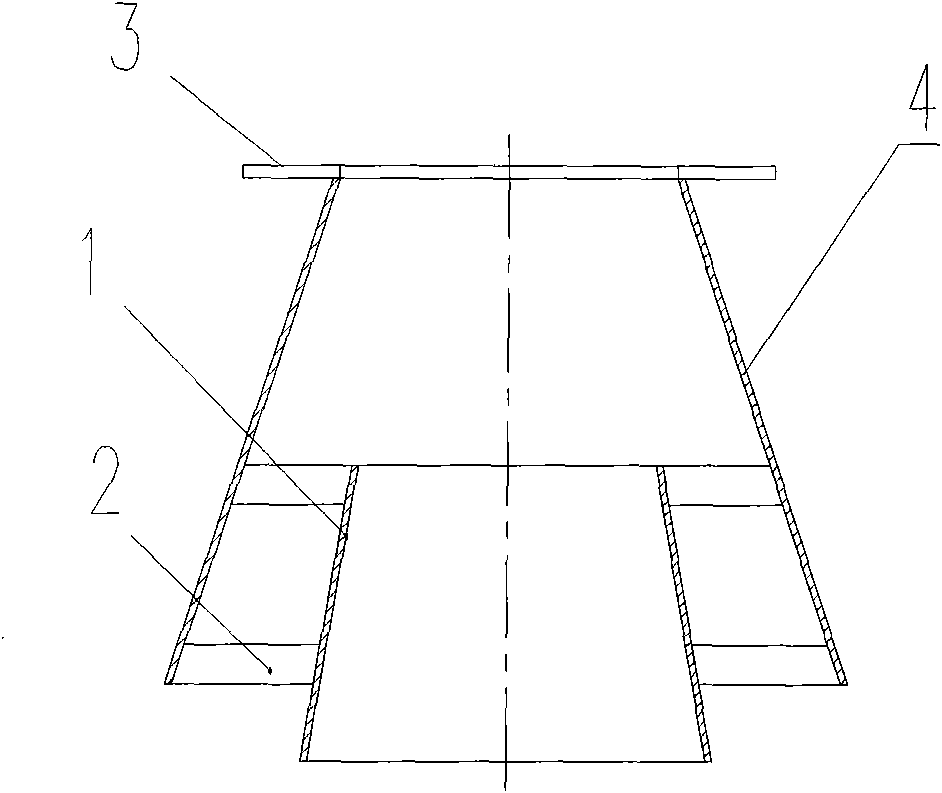

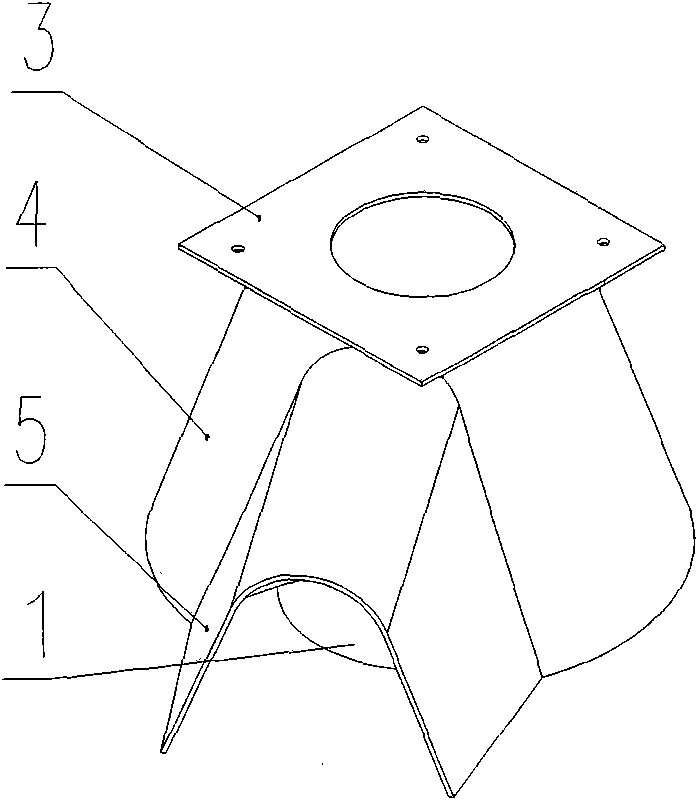

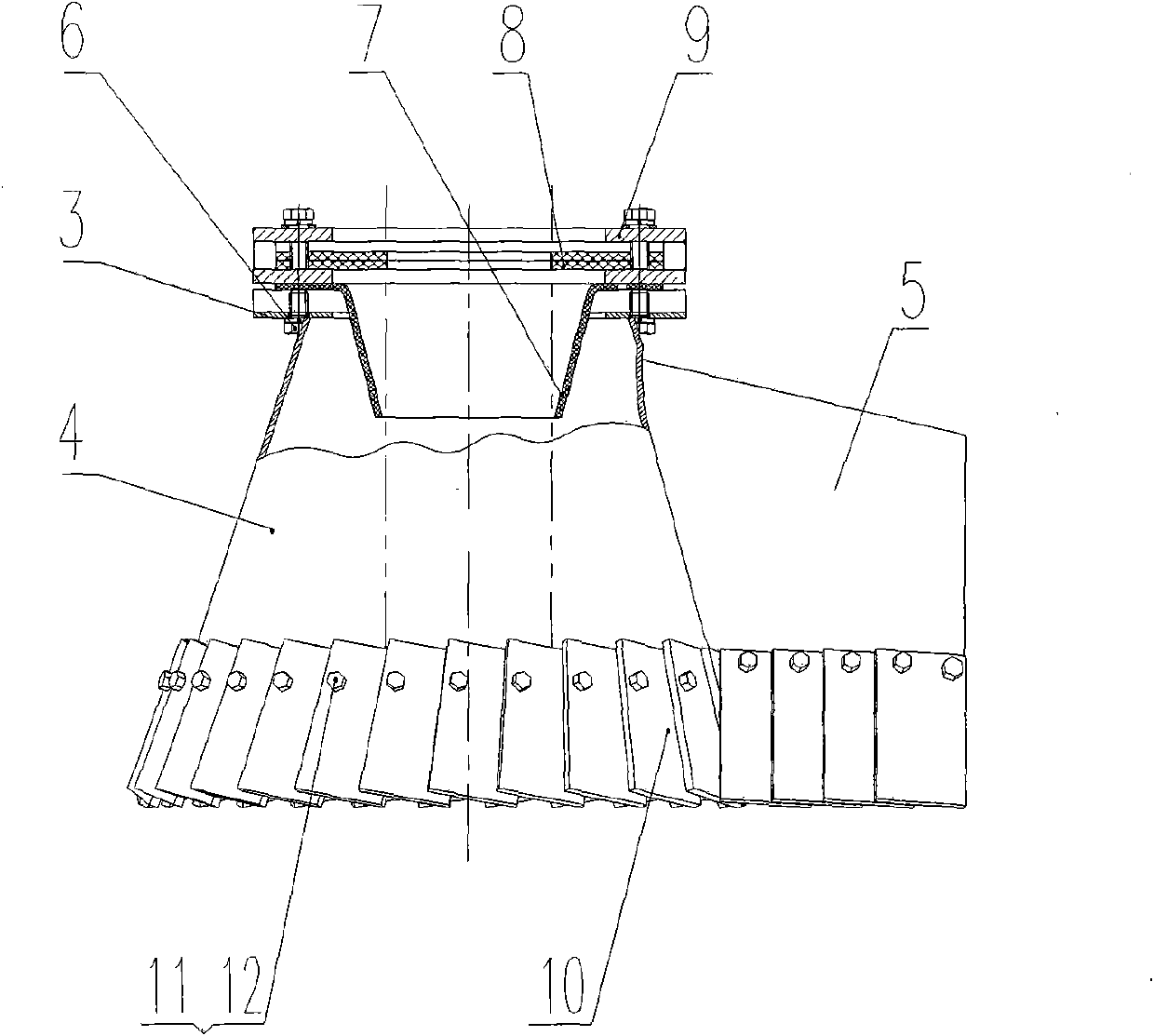

[0015] like figure 1 , figure 2 and image 3 As shown, the inside of the outer cover 4 is welded with the inner cover 1 through the connecting plate 2, the dust outlet 5 is welded on the side wall of the outer cover 4, the mounting plate 3 is welded on the top of the outer cover 4, and the cup-shaped sealing cover 7 and the annular sealing plate 8 pass through the pressure plate 9 and mounting screw 6 are installed on the mounting plate 3, and the bottom edge of the outer cover 4 and the dust outlet 5 is equipped with a dust-proof belt plate 10 by connecting screws 11 and connecting nuts 12.

[0016] like figure 1 , figure 2 and image 3 As shown, the dust collecting cover of the drilling rig of the present invention is simple in structure, easy to manufacture and easy to install. Because the cup-shaped sealing cover 7 and the annular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com