In-situ solidification and segregation treatment method of heavy-metal industrial polluted field

An in-situ solidification and heavy metal technology, applied in the field of contaminated site treatment, can solve the problems of poor effect, high cost, complicated technology, etc., and achieve the effect of low cost, quick effect and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A chemical plant in the suburbs of a certain city was relocated, and the soil at the original plant site was analyzed. It was basically not polluted by copper, zinc, cadmium, and arsenic, but it was slightly polluted by chromium, lead, and seriously polluted by mercury (see Table 1 and Table 2 for the pollution status) . Due to the impact of heavy metal ions, the engineering and environmental protection indicators of the foundation soil do not meet the requirements of national standards, so the contaminated soil should be treated before the secondary development.

[0033] Table 1 Environmental background value of heavy metals in the city's soil mg·kg -1

[0034] Cu

Pb

Zn

Cr

Cd

Hg

As

32.2

24.8

76.68

59.00

0.19

0.12

10.6

[0035] Table 2 Statistics of heavy metal content in soil near the chemical plant site

[0036] Metal

number of samples n

Min /

mg·kg -1

Ma...

Embodiment 2

[0053] An electroplating factory in the suburbs of a certain city was relocated. The soil in the original factory site was seriously polluted by zinc ions. The local groundwater level was 2 meters below the surface. Heavy metal ions easily migrated to the surroundings through the groundwater, affecting the surrounding ecological environment.

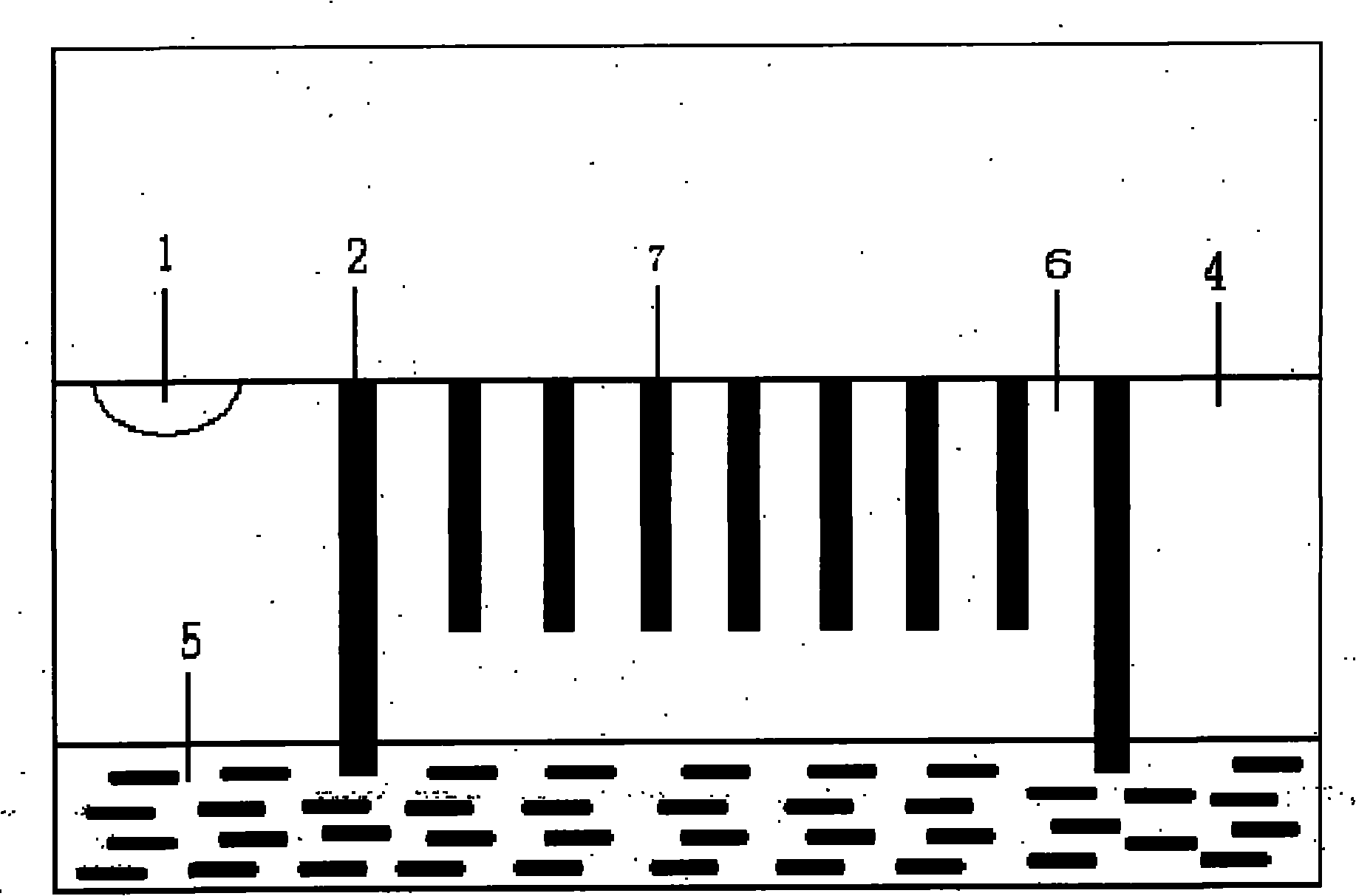

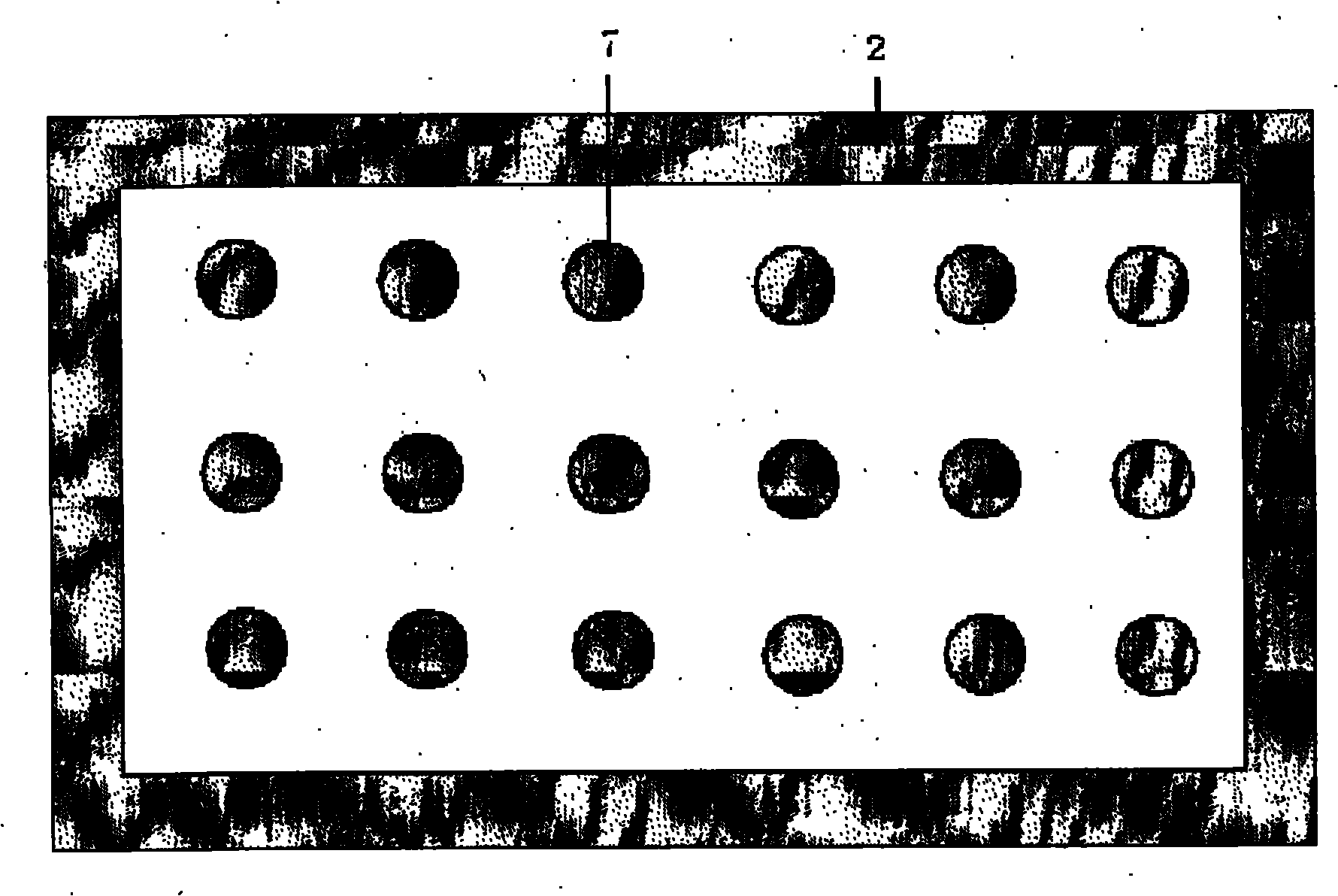

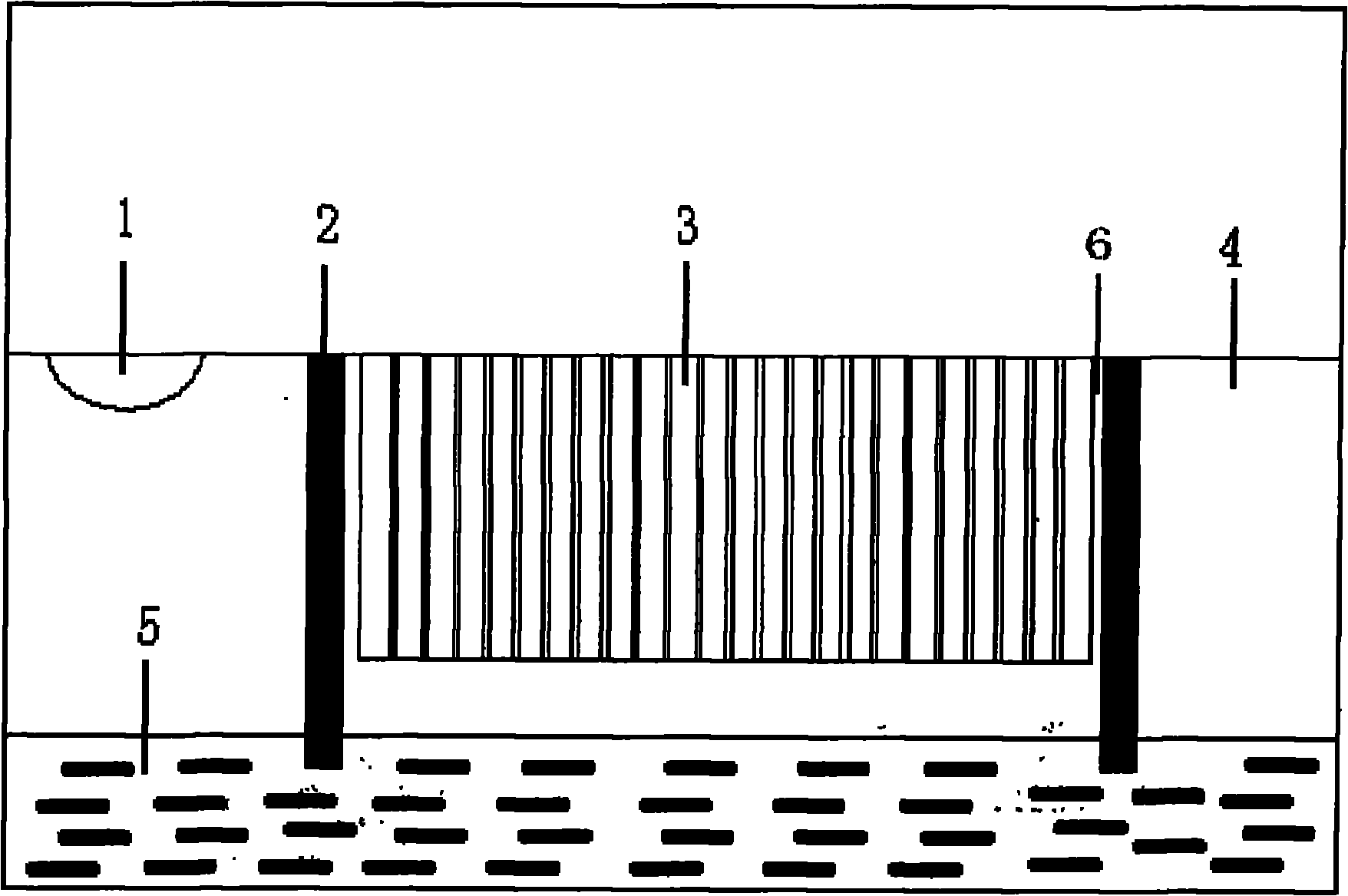

[0054] The area is mainly composed of soft clay with low strength and poor self-supporting properties. In addition, it is severely polluted by heavy metals. Therefore, it is decided to use deep-layer occlusal piles 3 inside the site, and use deep-layer occlusal pile technology to form a separation wall 2 around the site, such as image 3 and Figure 4 shown. After investigation, there is an impermeable layer 5 at 8m underground, so the separation wall directly penetrates the impermeable layer 1m to prevent pollutants from spreading with groundwater.

[0055] (1) Treatment in the polluted area using deep-layer mixing pile method: set up ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pile diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com