Annular Turning Tool for Ceramic Cylindrical Machining and Axial Machining Method

A turning tool and tool technology, applied to the annular axial turning tool and its processing field, can solve the problems of high cost and low processing efficiency, achieve simple application and maintenance, low equipment investment and operating costs, and ensure processing efficiency and processing efficiency. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The annular turning tool and the axial processing method thereof proposed by the present invention for ceramic cylindrical processing are further described as follows in conjunction with accompanying drawings and examples:

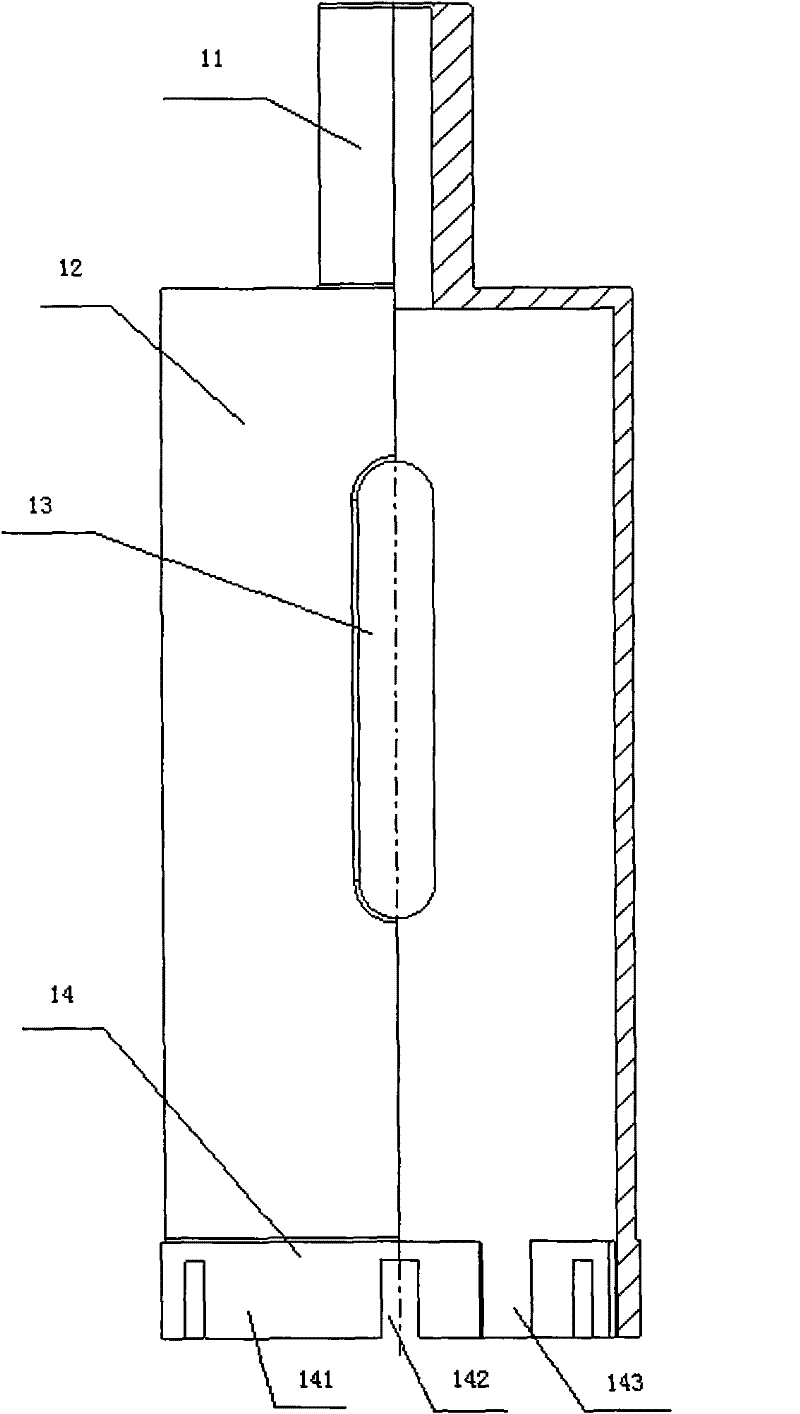

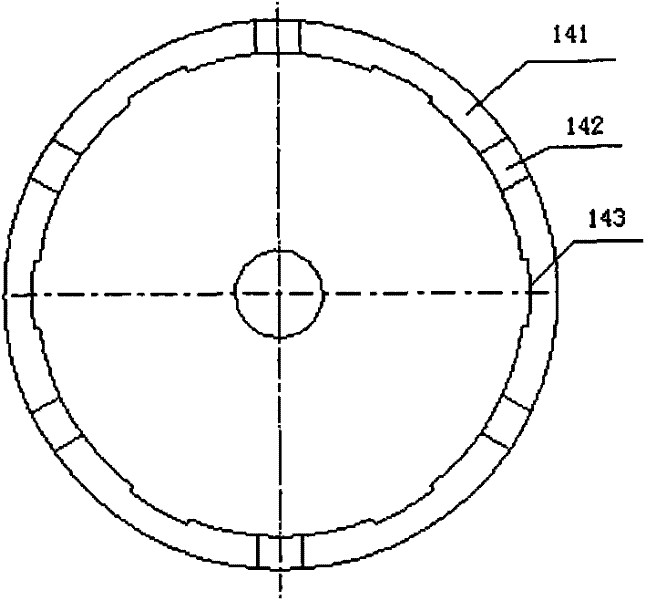

[0022] The present invention is used for the annular turning tool structure of ceramic outer circle processing such as figure 1 , 2 As shown, the cutter is mainly composed of a tool handle 11, a cutter body 12 and a cutter head 14 which are connected coaxially in sequence. The handle 11, the cutter body 12 and the cutter head 14 are all hollow tubes, and There is a balance groove 13; the cutter head 14 is composed of cutter teeth 141, a through groove 142 formed between two cutter teeth and a tooth groove 143 formed on the inner surface of the cutter teeth. The balance groove 13 mainly balances the air pressure inside and outside the cutter body during processing, and the coolant can also enter from it to cool and lubricate the cutter and the workp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com