Wood cutting machine and wood cutting and processing method

A technology of cutting machine, wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

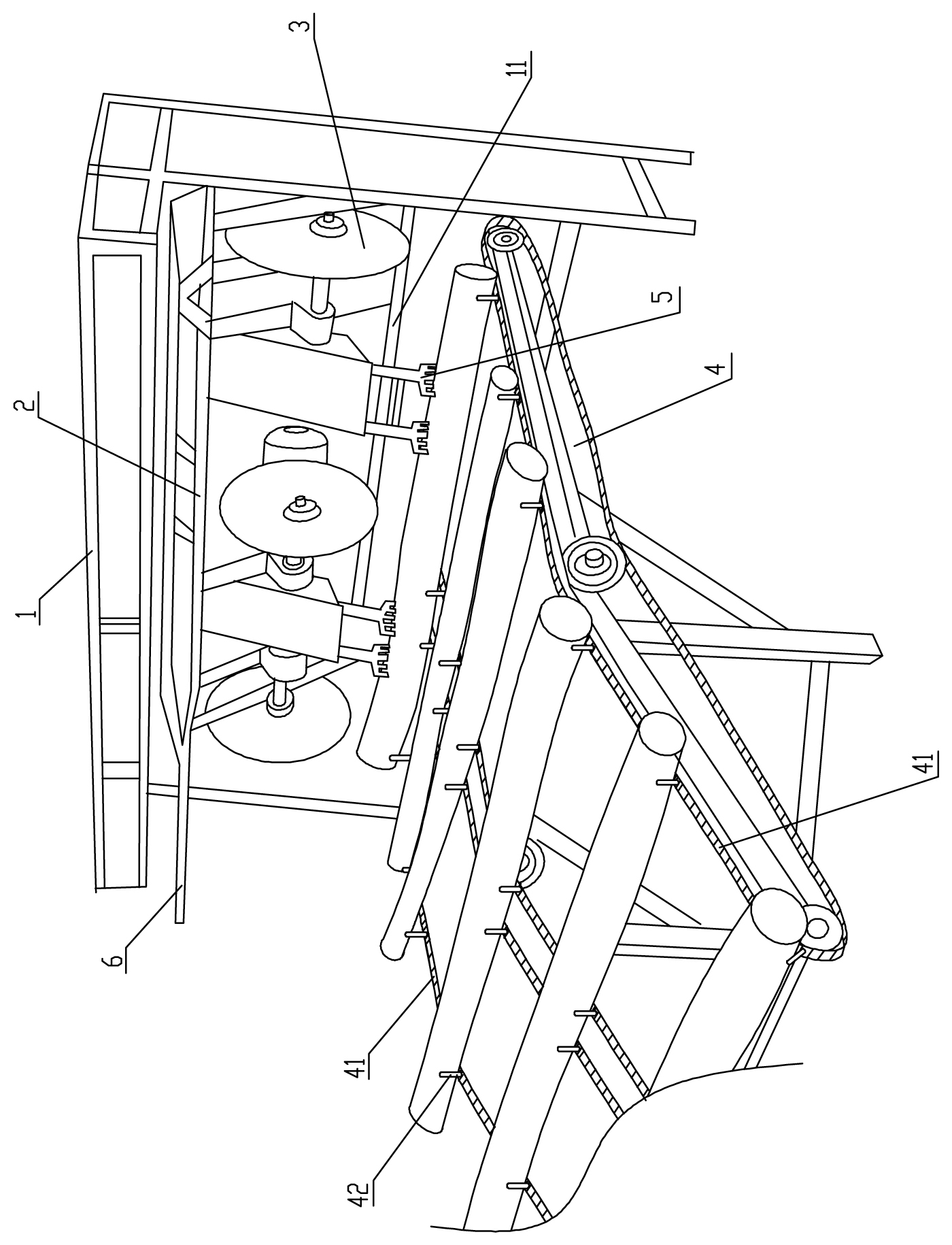

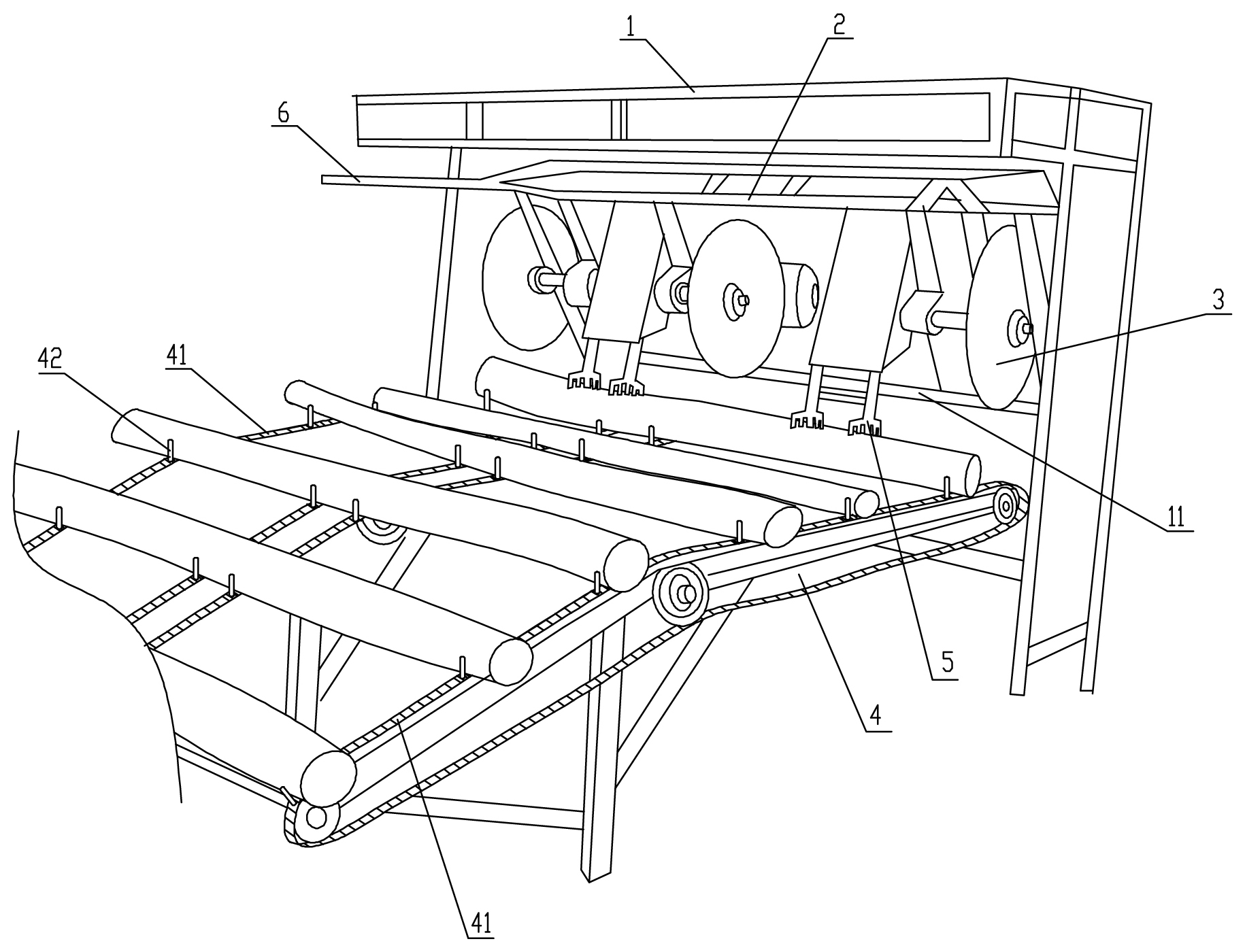

[0022] refer to figure 1 As shown, a wood cutting machine includes a fixed frame 1, and the fixed frame 1 is installed with a movable frame 2 through the rotation of the rotating shaft. The center lines are distributed sequentially. The fixed frame 1 is provided with a bracket 4 for placing logs under the cutting piece 3. The fixed frame 1 is also equipped with a stretchable and retractable metal pressing piece 5. When the metal pressing piece 5 stretches out The log is pushed down and the log is cut off by the cutting blade 3 . The metal press 5 is controlled by pneumatic means. During processing, start the motor first, and the motor drives the cutting piece to rotate at high speed. In order to improve work efficiency, the motor that controls the cutting piece does not need to be stopped during the processing, so that the logs below can be cut at any time, which improves efficiency and reduces The service life of the motor is affected by frequent starting; then the log to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com