Tamping device with independent hydraulic shock excitation and clamping movement

A vibration-exciting and hydraulic technology, which is applied to roads, tracks, ballast layers, etc., can solve the problems of destroying the working environment of the hydraulic system of the tamping device, and achieve the effects of increasing life, protecting stability, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

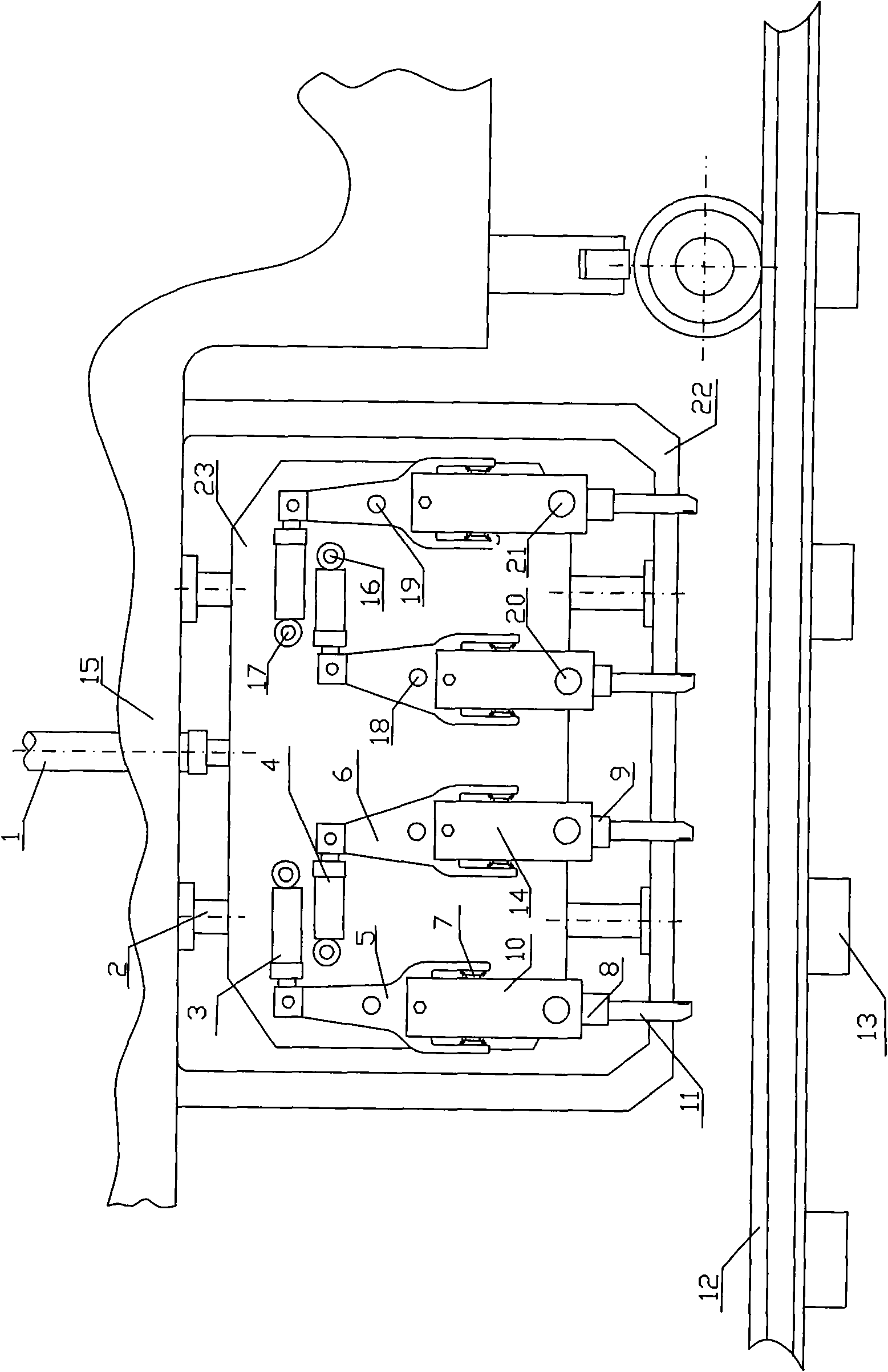

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

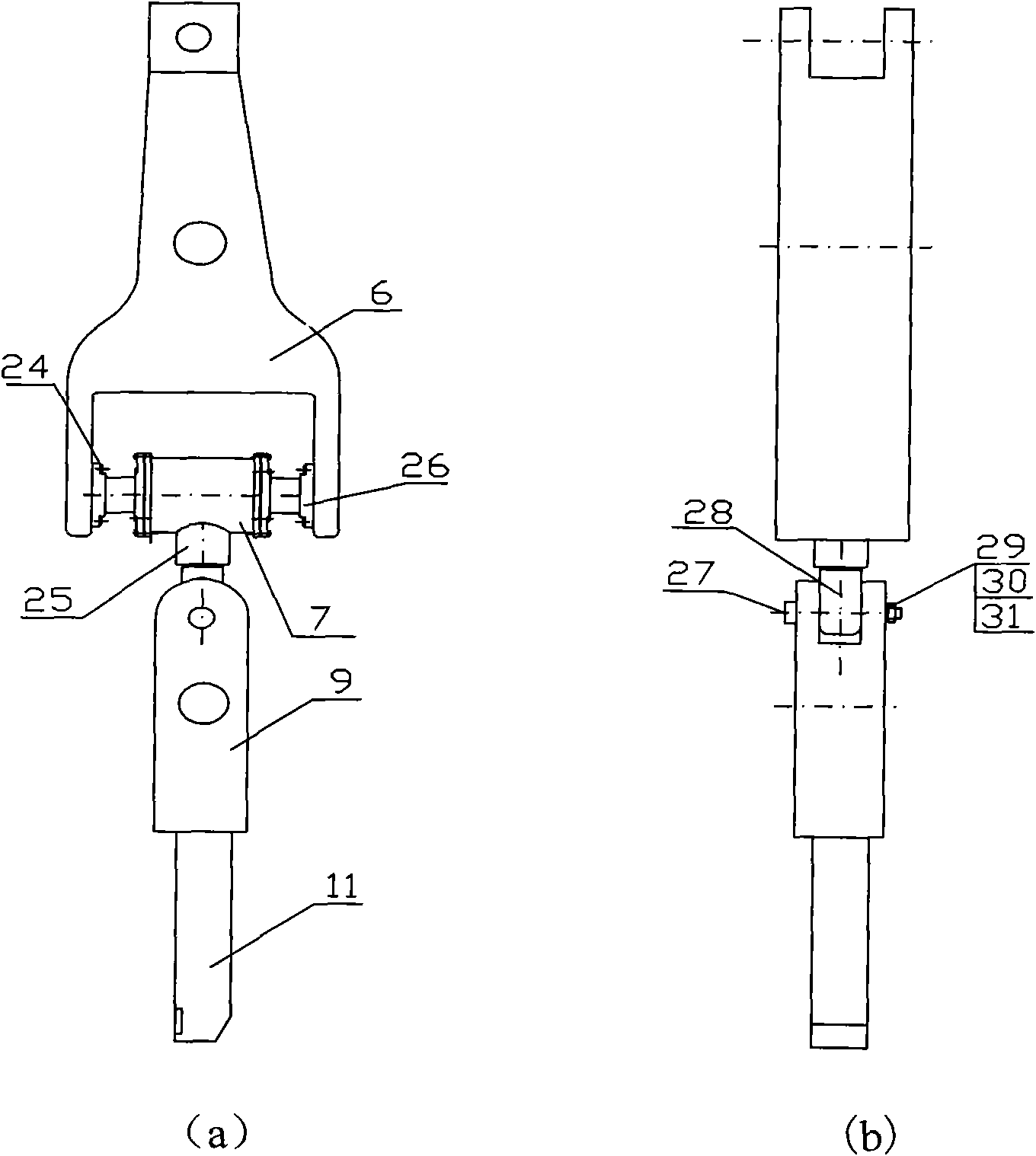

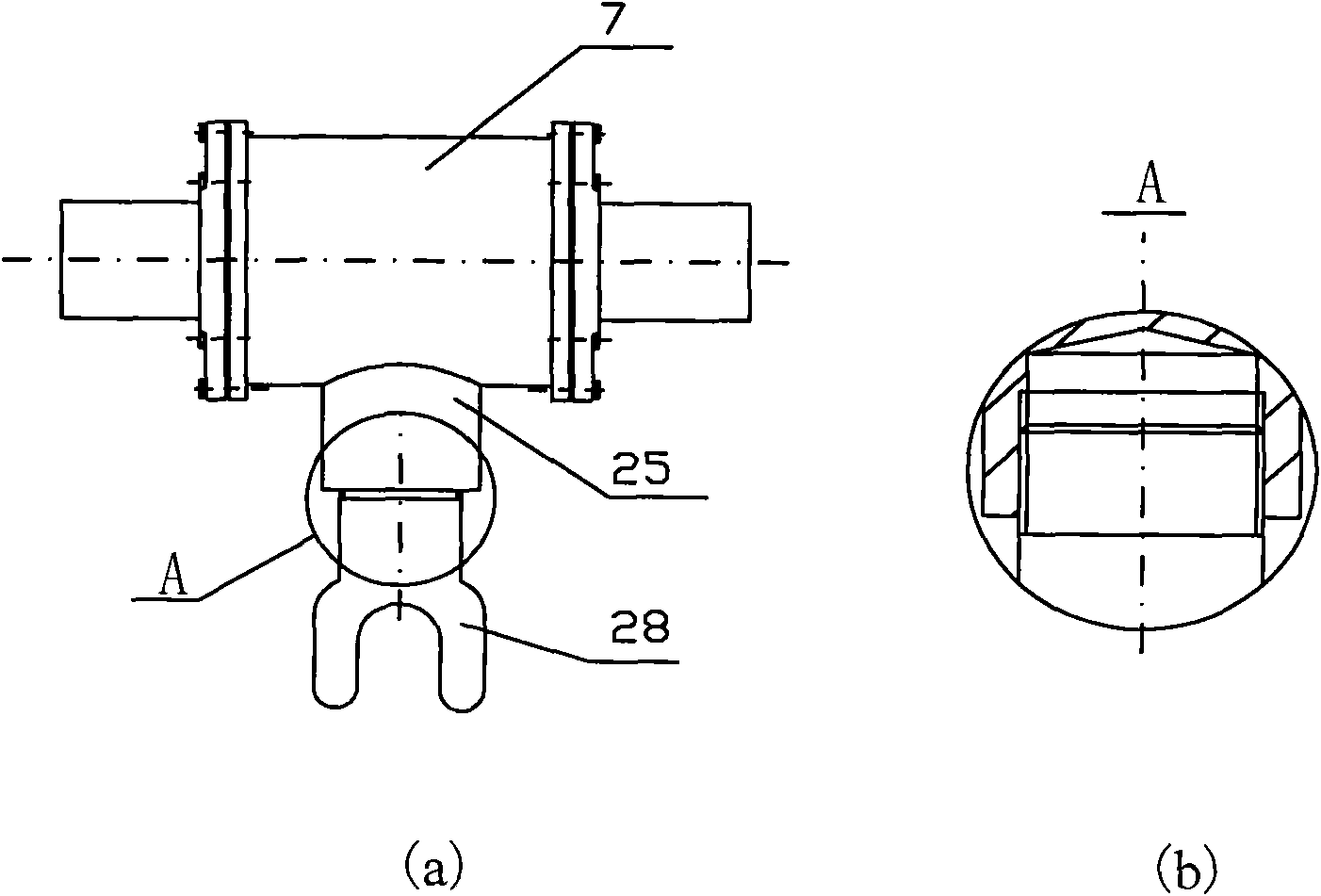

[0022] Figure 1 to Figure 7 An embodiment of the present invention is shown, and the excitation hydraulic cylinder in this embodiment is a double-rod hydraulic cylinder.

[0023] Such as figure 1 As shown, the tamping device is fixed on the frame 22 of the tamping trolley 15 . The tamping device comprises a tamping box body 23 capable of lower insertion movement, an inner tamping head and an outer tamping head installed oppositely on the two sides of the tamping box body 23 . The lower insertion movement of the tamping box 23 is realized by the lifting hydraulic cylinder 1 on the tamping trolley 15. In order to prevent twisting and deflection during the lower insertion of the tamping box 23, two vertical guides are installed on the tamping trolley frame 22. Column 2, these two guide columns have also ensured the lower insertion depth of tamping box 23.

[0024] Suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com