Push-pull-type hydraulic power pile-sinking machine

A technology of hydraulic power and pile driving machine, which is applied in the direction of sheet pile wall, building, foundation structure engineering, etc. It can solve the problems of pile bearing capacity corrosion, high noise source, etc., and achieve the effect of convenient processing and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

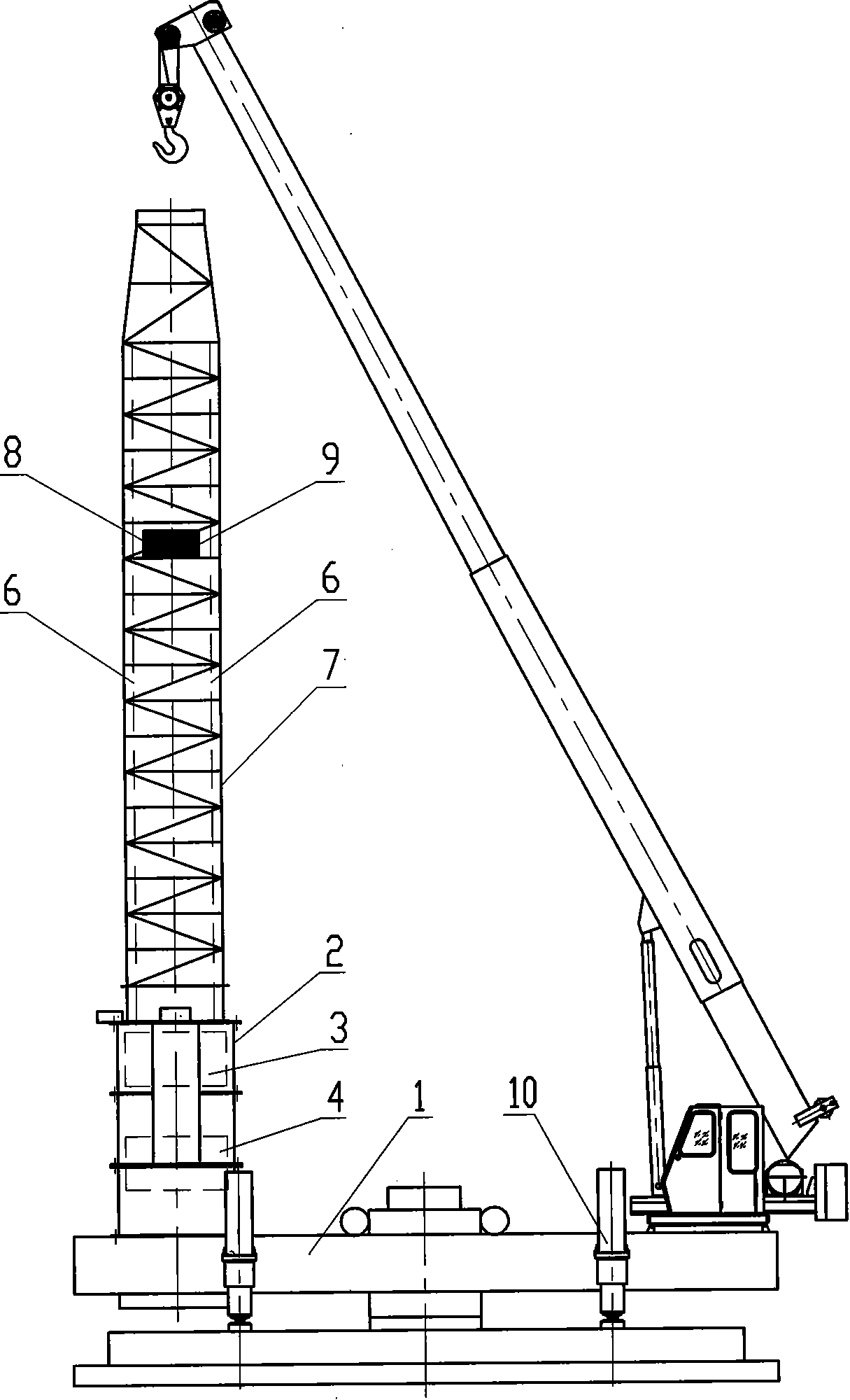

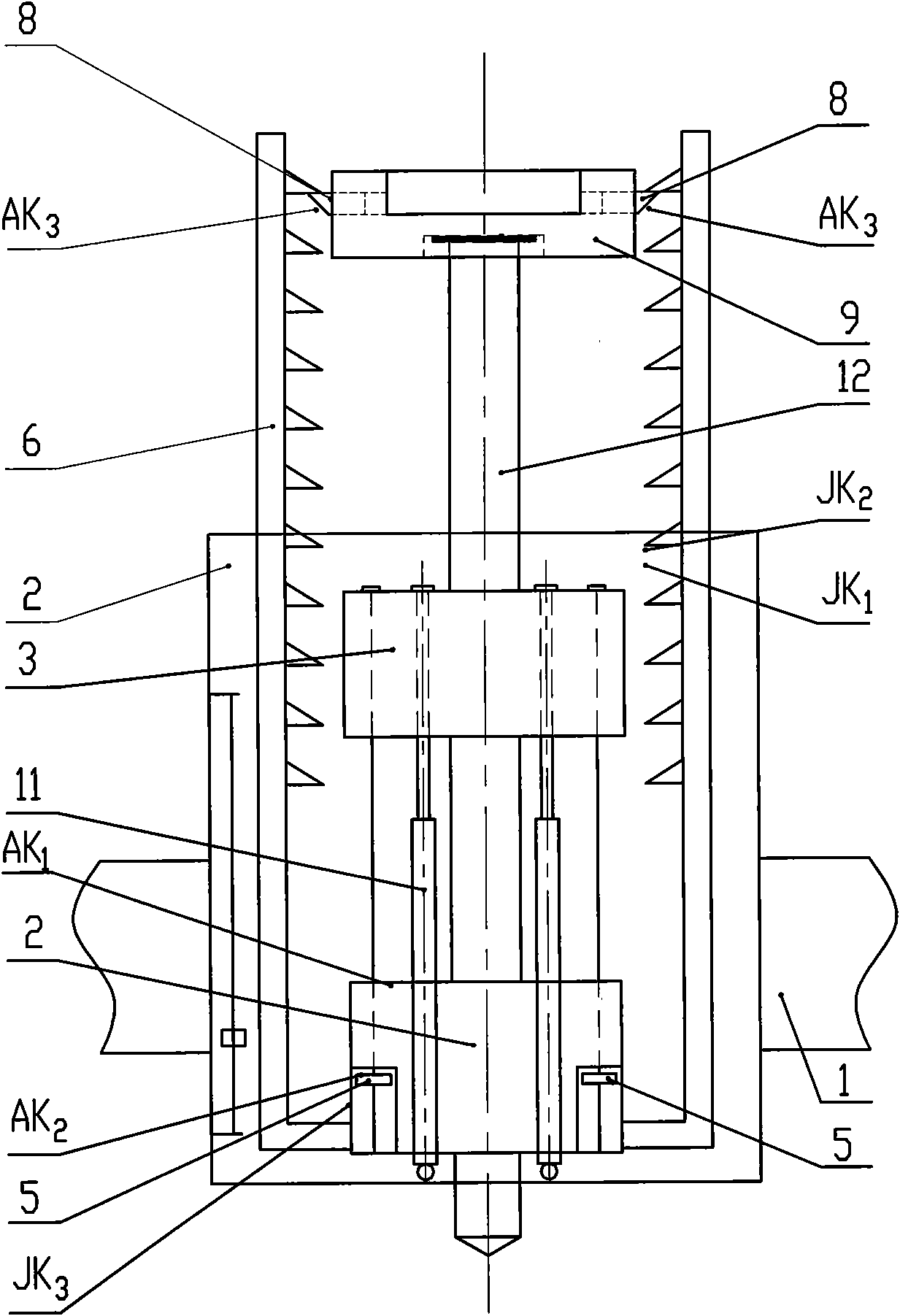

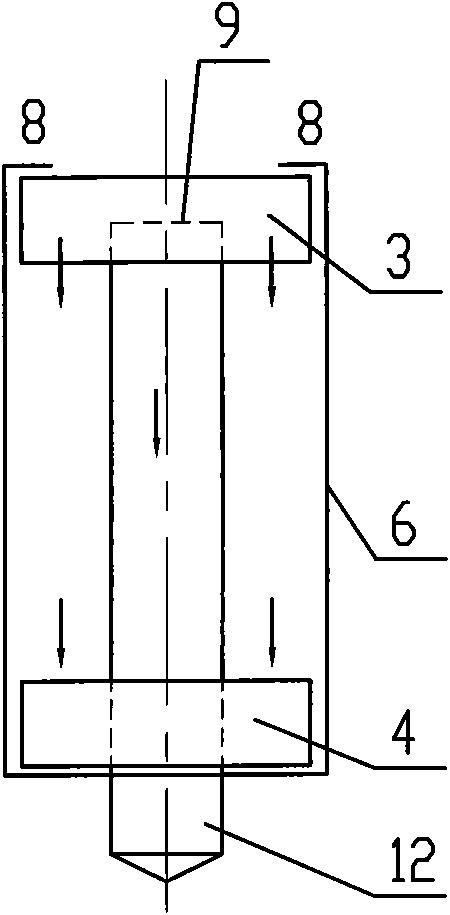

[0034] see figure 1 , is a schematic diagram of the top-pull hydraulic power pile driving machine of the present invention, which mainly includes a power chamber 2 fixed in the main frame 1, the power chamber 2 is a square long cylinder, and an openable and closable The door is used for hanging piles. The power chamber 2 is provided with an impact body 3, a compressed tension box 4, an impact regulator 5, a penetration detection device, etc., and a guide frame 7 is installed on the top of the power chamber 2 to guide There are pull rods 6 on both sides of the frame 7, a pile cap 9 with a tongue 8 and a lifting translation mechanism in the middle, and a lifting leg 10 is set on the main frame 1, most of which have been outlined in Chinese patents 200620052177.7 and 200920064321.2 , which will not be described in detail here, and the improvements of the present invention will be described below.

[0035] Such as figure 2 As shown, the lifting cylinder 11 is changed from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com