Electromagnetic control variable plunger pump

A variable plunger, electromagnetic control technology, applied in the field of hydraulic parts, can solve the problems affecting the service life of the variable pump, the components are easily damaged by friction, and the requirements of high manufacturing accuracy, and achieve low oil quality and cleanliness requirements, reliable work, and machining accuracy. less demanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

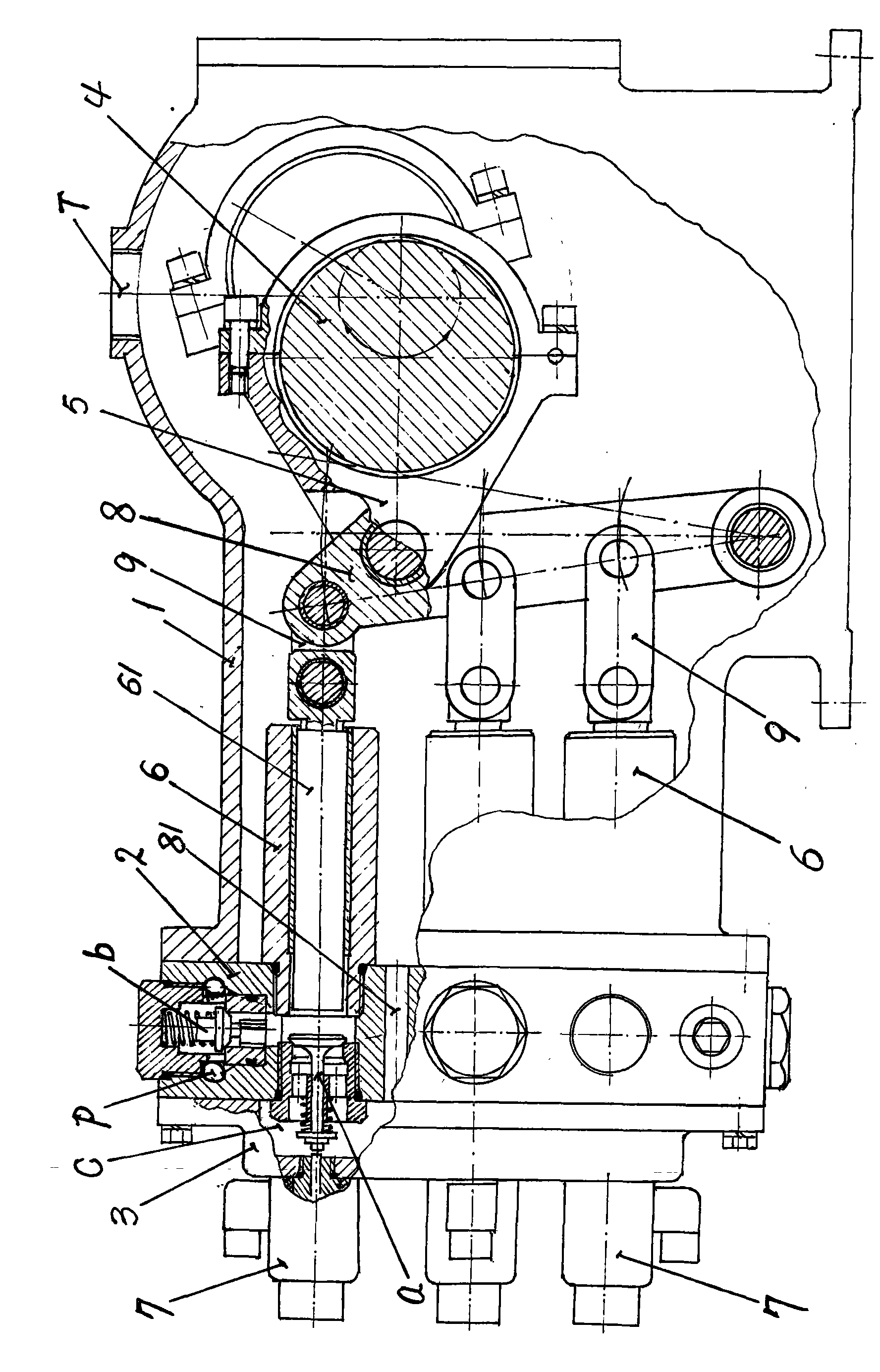

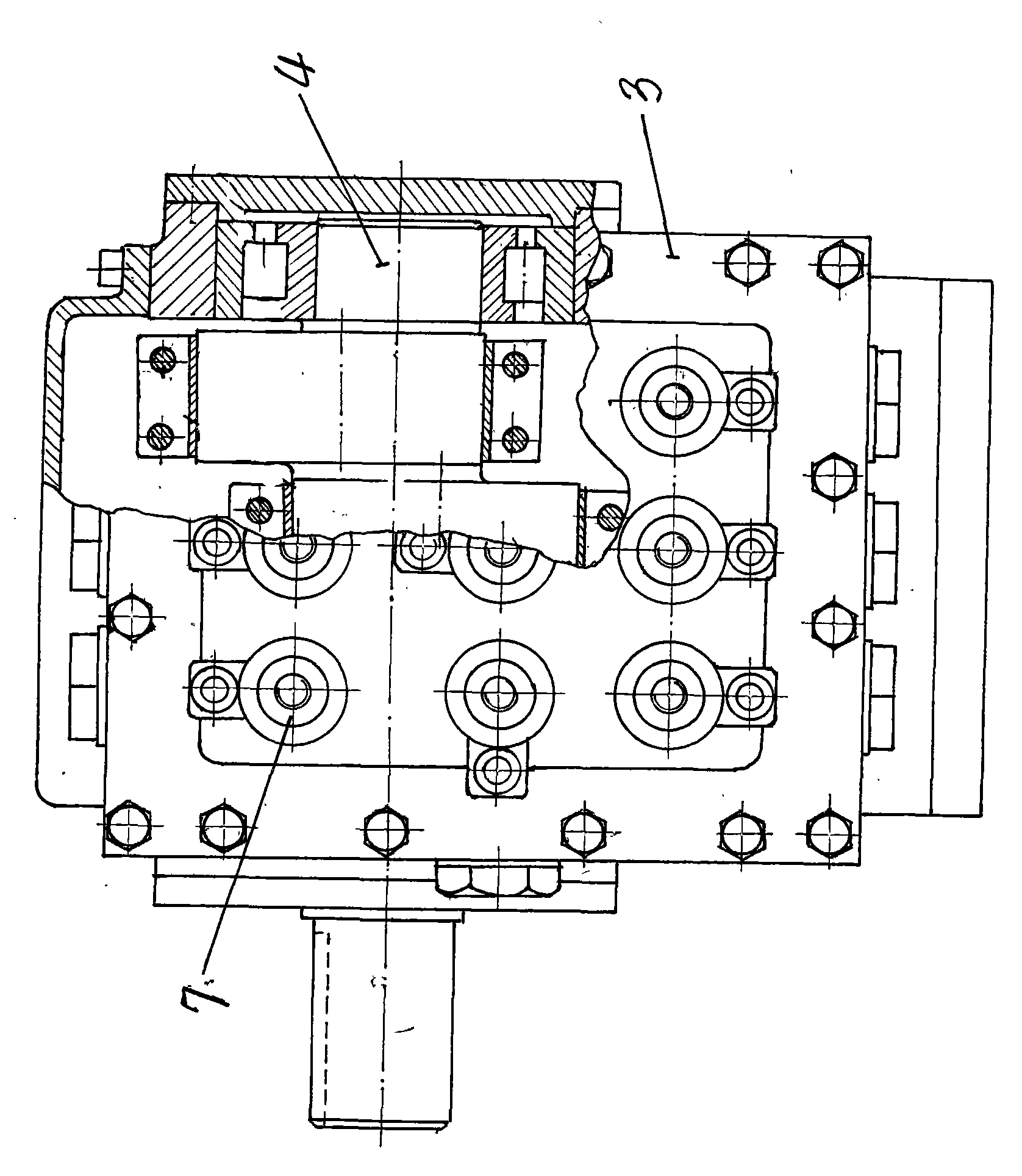

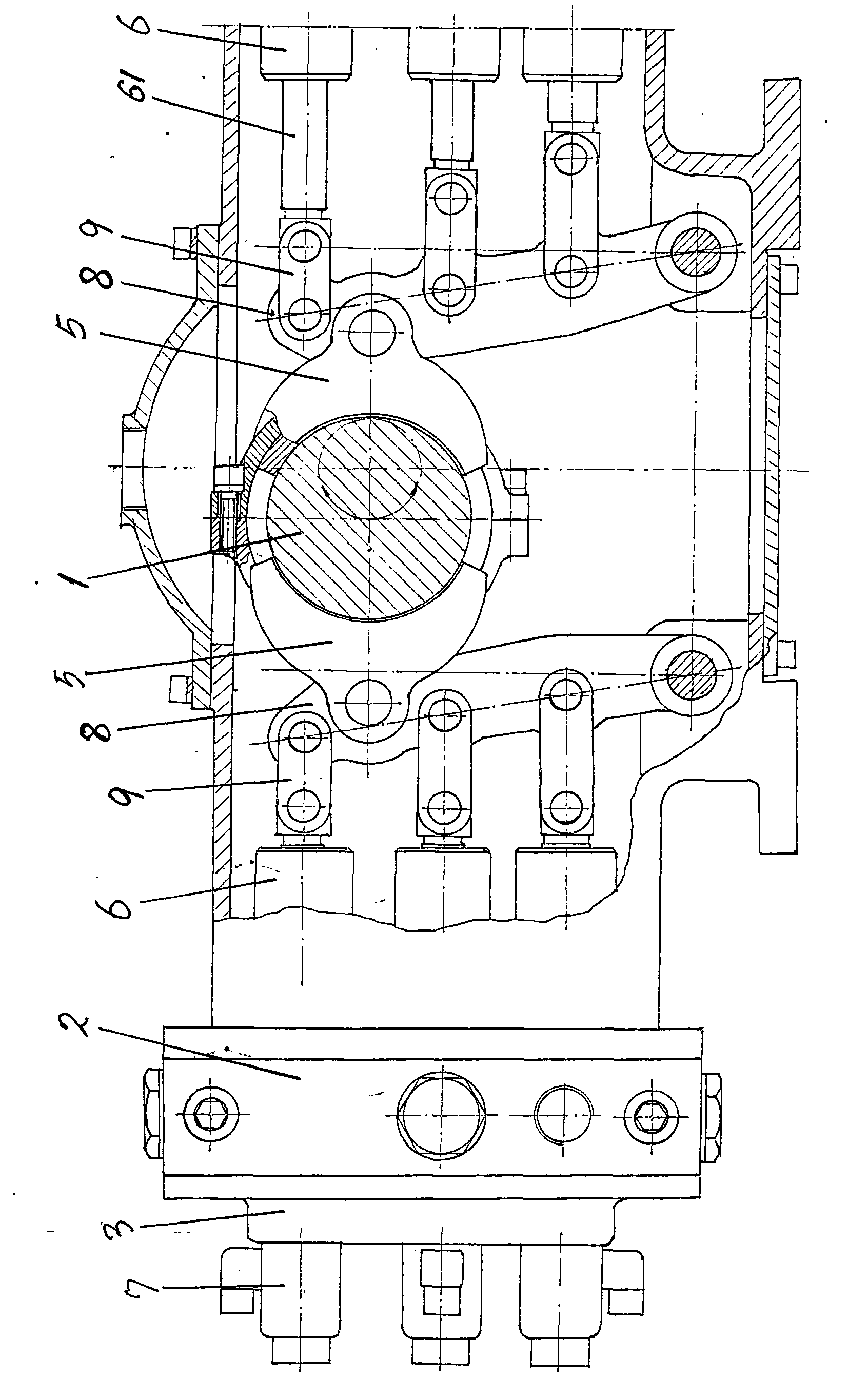

[0012] The present invention includes pump casing 1, valve plate 2, valve cover 3, crankshaft 4, crankshaft connecting rod 5, several plunger cylinders 6, several electromagnet devices 7 corresponding to each plunger cylinder 6, valve plate 2 and pump casing 1 Sealed and fixed connection, the valve cover 3 is sealed and fixed with the valve plate 2, the plunger cylinders 6 are arranged and fixedly installed on the valve plate 2 in the pump casing 1, and the single or multi-crank crankshaft 4 is installed in the pump casing 1 through the bearing device , each eccentric shaft corresponding to the multi-crank crankshaft 4 in the pump casing 1 is hingedly connected with the pump casing 1 to set a swing rod 8, the crankshaft connecting rod 5 is hingedly connected to the swing rod 8, and the plunger cylinder 6 is arranged and distributed corresponding to the swing rod 8, each The plunger rod 61 of the plunger cylinder 6 is hingedly connected with the swing rod 8 through its connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com