High-clearing-point electro-liquid-crystal atomized glass

A technology of atomizing glass and clearing points, which is applied in optics, instruments, nonlinear optics, etc., and can solve the problem of glue opening, poor adhesion between liquid crystal-plastic core layer and transparent conductive film, glass stress, liquid crystal-plastic core layer Solve the problems of separation from transparent conductive film, etc., to solve the effect of glue opening, clear point improvement, and enhanced adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

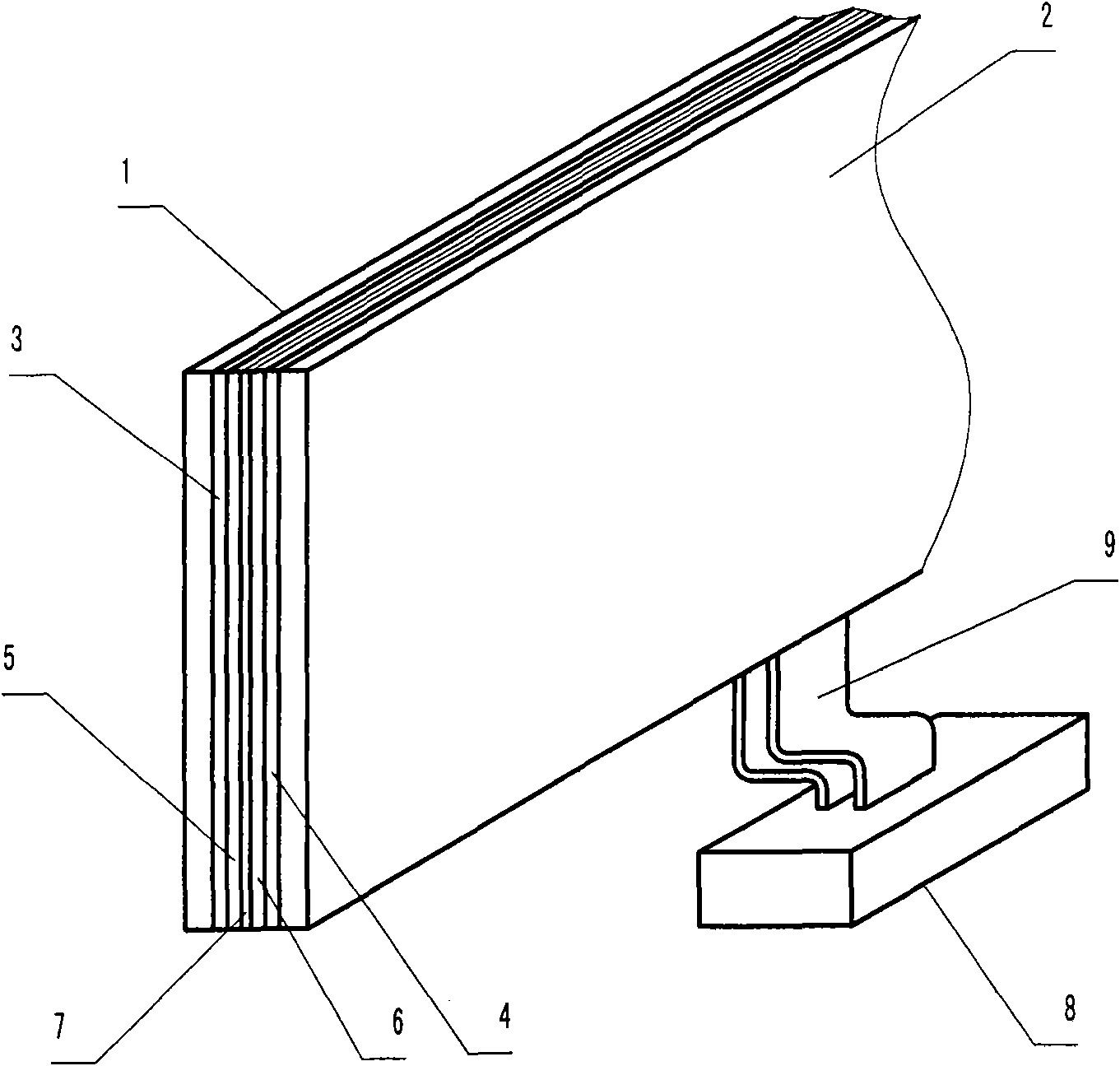

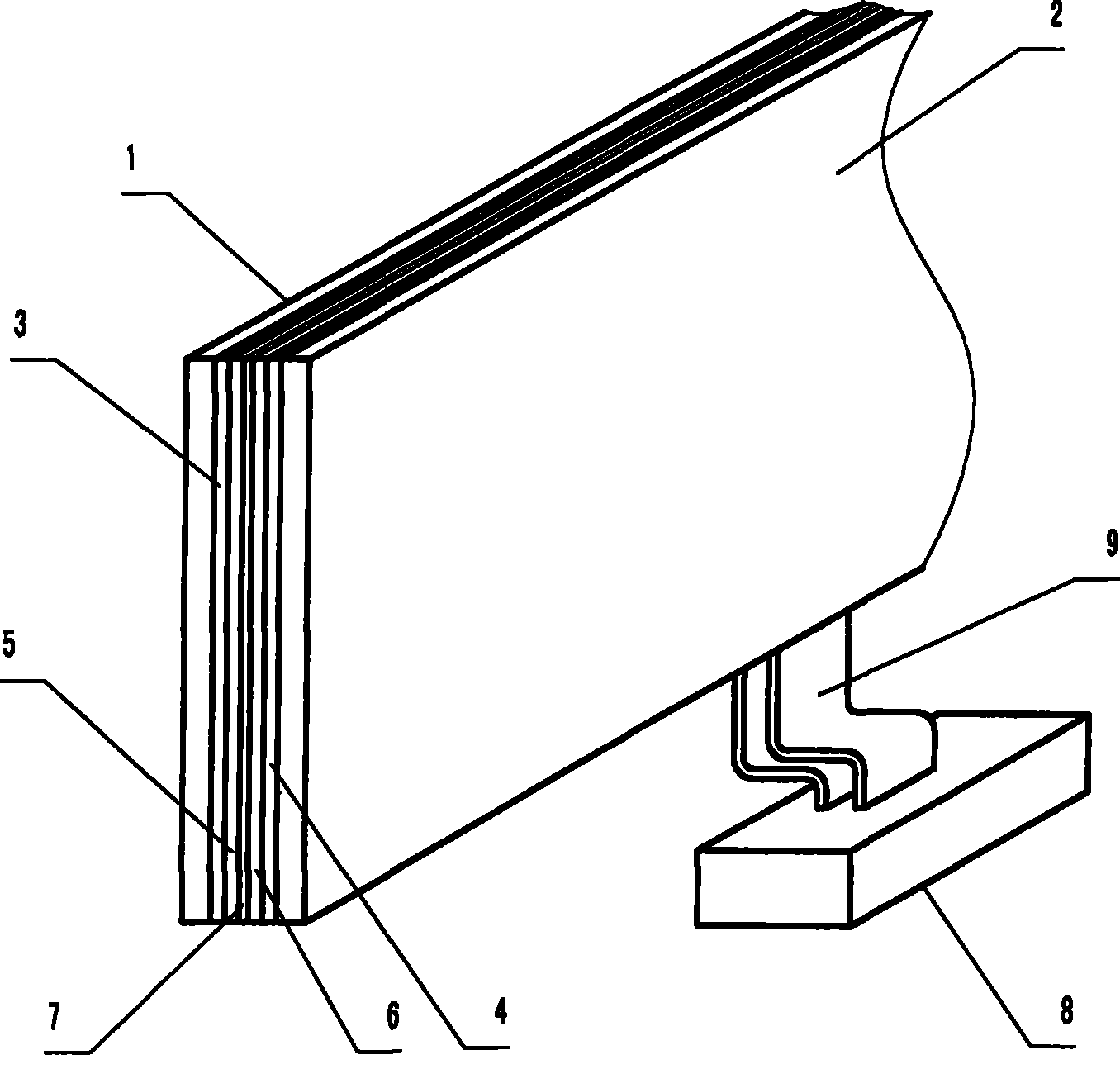

[0017] see figure 1 (partial view of the present invention), the electroluminescent liquid crystal atomized glass (also called dimming glass) of the present invention has a plastic type liquid crystal film, transparent glass plates 1, 2 are symmetrically arranged on both sides of the liquid crystal film, and The transparent glass plate and the plastic liquid crystal film are compounded with heat-cured transparent adhesive layers 3 and 4, and the transparent glass plate and the plastic liquid crystal film are combined into one body through the heat-cured transparent adhesive layer. The plastic-type liquid crystal film described above comprises a liquid crystal-plastic core layer 7 and two (sheets) symmetrically arranged transparent conductive film surface layers 5, 6, and each transparent conductive film is provided with a strip-shaped electrode that can generate a uniform electric field (Fig. Not shown in ), the strip electrodes are electrically connected to a controller 8 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com