Pneumatic rotary air plasma jet source

An air plasma and plasma technology, which is applied in the field of ion jet sources, can solve problems such as difficulty in realizing the surface treatment process of air plasma jets, and achieve the effects of improving energy efficiency, reducing costs, and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

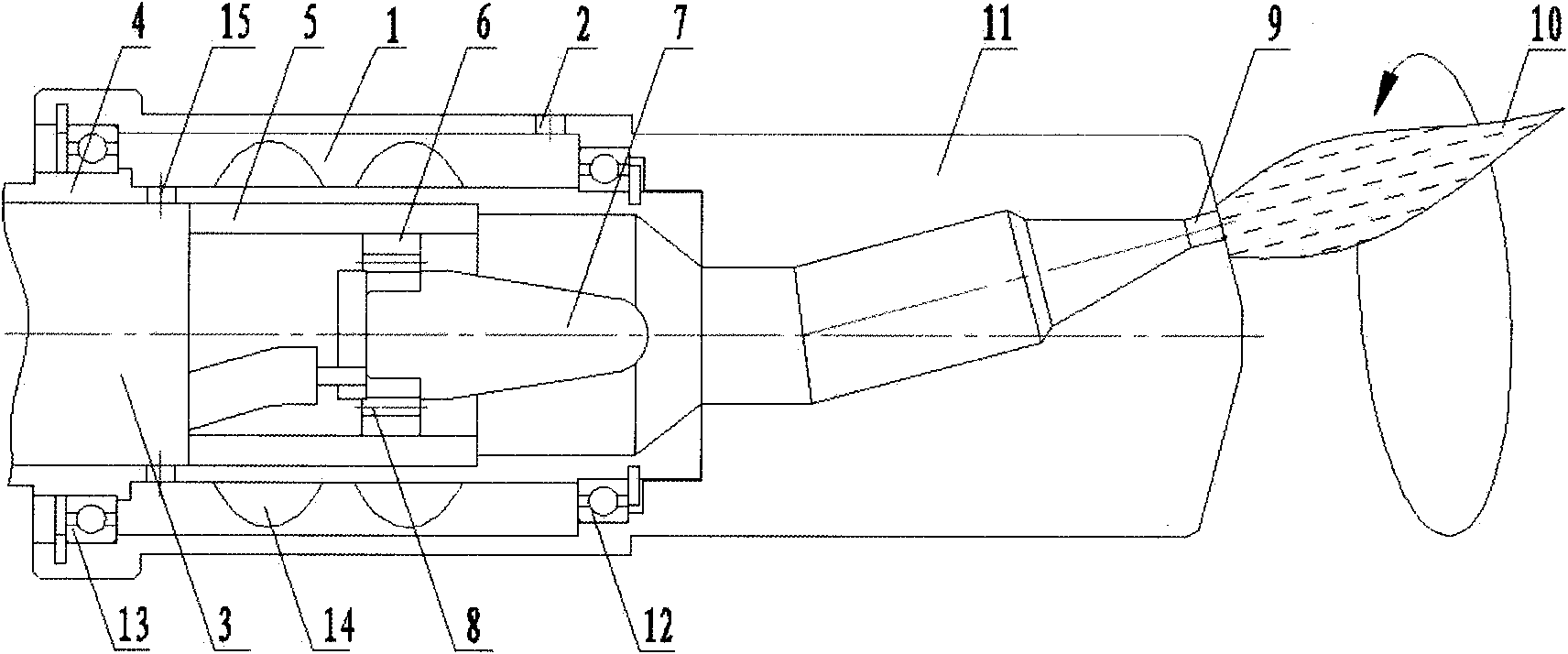

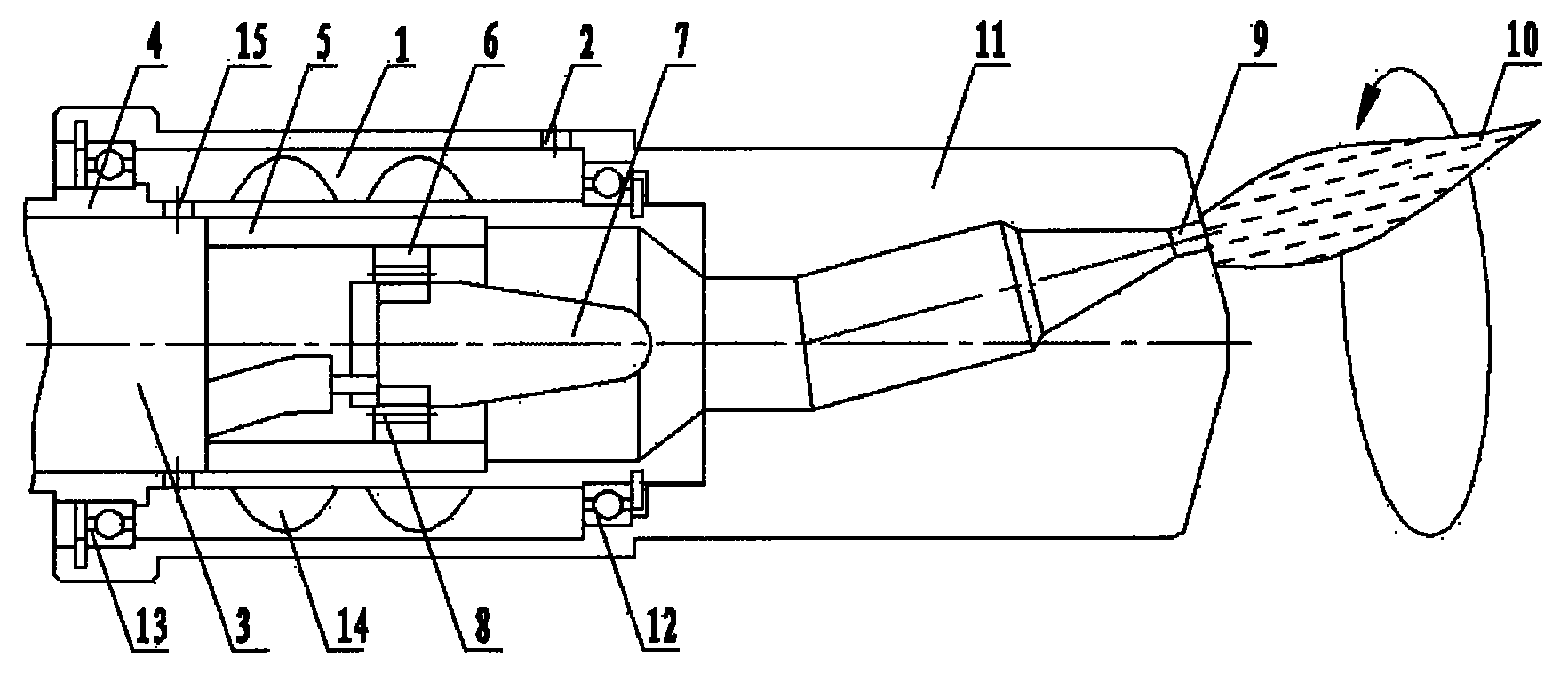

[0025] Such as figure 1 As shown, the pneumatic rotating air plasma jet source includes an inner electrode 7 , an air supply ring 6 , an insulating ring 5 , an outer electrode inner cylinder 4 , an outer electrode outer cylinder 11 , and bearings 12 and 13 . The rear part of the outer electrode inner cylinder 4 is the gas chamber 3, and a part of the gas in the gas chamber 3 enters the inner electrode 7 and the outer electrode inner cylinder 4 through the air channel 8 of the gas supply ring 6, and the passage at the front of the outer electrode outer cylinder, through The nozzle 9 flows out to provide a discharge to eject the plasma jet 10; since the axis of the nozzle 9 forms an included angle with the axis of the inner electrode 7, the plasma jet 10 ejected by the discharge deviates from the axis of the inner electrode. The other part of the gas in the gas chamber 3 enters the pneumatic rotating chamber 14 through the through hole 15 on the inner cylinder 4 of the outer ele...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap