Cyclonic water filtration dust collecting device

A dust collection device and water filtration technology, which is applied in the direction of suction filter, etc., can solve the problems of unsatisfactory water-air contact mixing effect, prolonging the residence time of airflow, and poor dust removal effect, achieving compact structure, prolonging residence time, and good dust removal effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

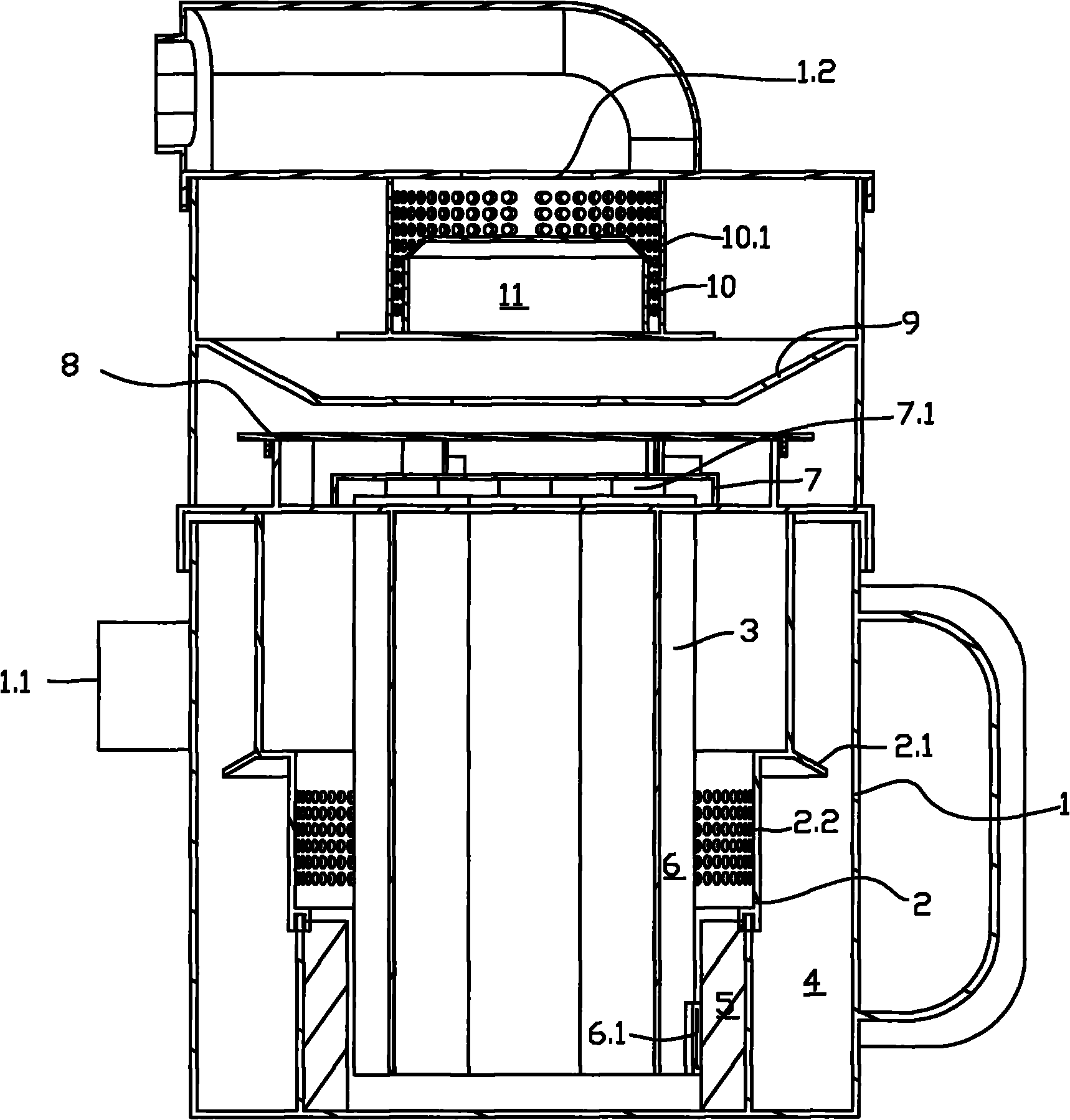

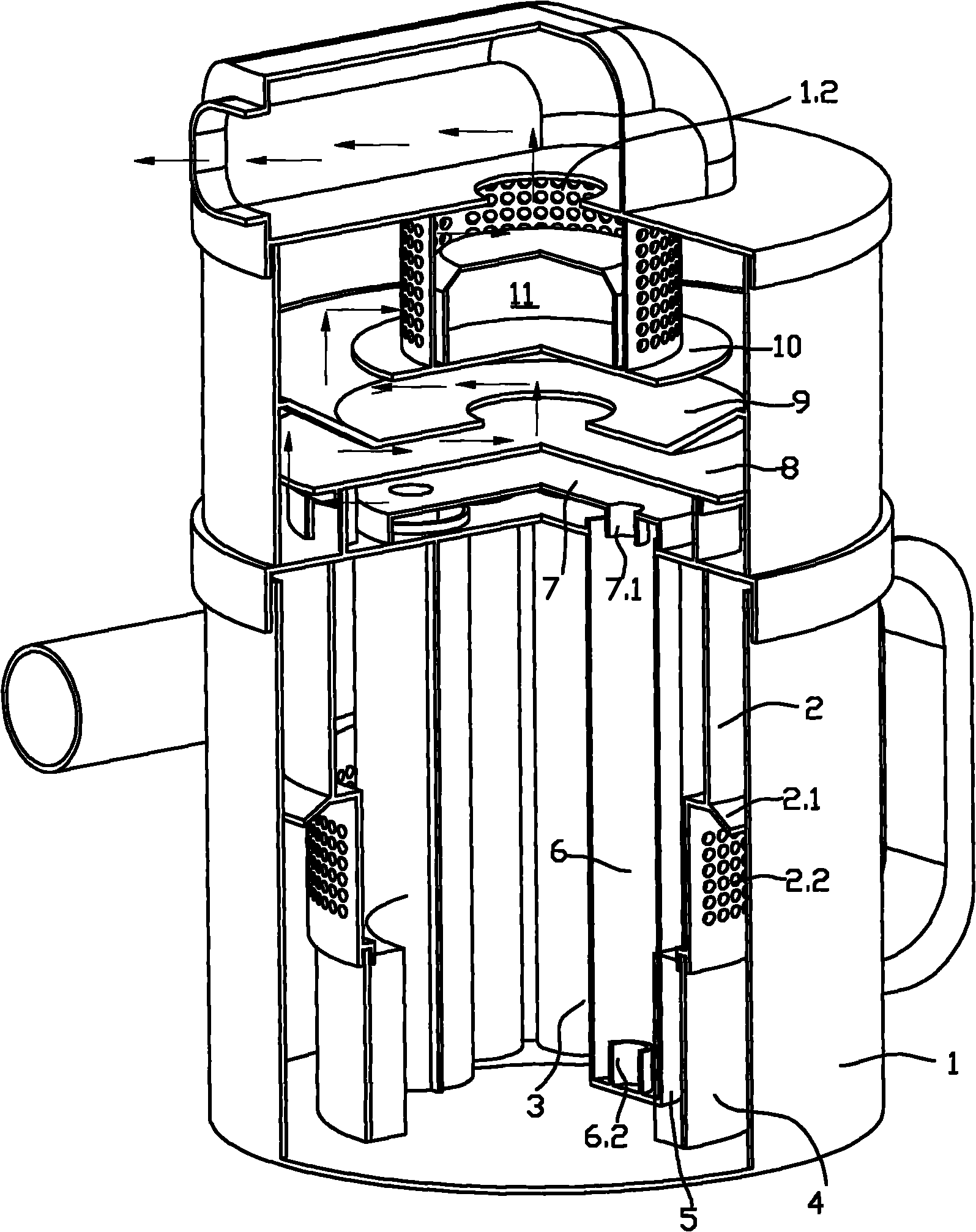

[0026] Such as Figure 1-6 As shown in the figure, a cyclone type water filter and dust collection device includes a dust bucket 1, a total air inlet 1.1, a total air outlet 1.2, a filter cartridge 2 as a primary filter, and a two-stage water filter 3, etc. Parts, the dust bucket 1 is arranged in the radial direction from the outside to the inside with the filter cartridge 2 and the water filter 3 that constitute the primary filter. The dust bucket 1, the filter cartridge 2 and the water filter 3 are arranged concentrically. Among them, the outer surface of the filter cartridge 1 is provided with an inclined dust cover 2.1 below the general air inlet, and a large particle dust dust chamber 4 is formed between the dust bucket 1, and the wall of the filter cartridge 2 is between the dust cover and the bottom edge. Filtration micropores 2.2 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com