Combined pile of pre-stressed wedge-shaped pipe pile and pre-stressed pipe pile

A prestressed pipe pile, prestressed technology, applied in the field of prestressed wedge pipe piles and prestressed pipe pile composite piles, can solve the problems of prestressed wedge pipe pile length, high pile bearing capacity, high processing costs, etc. Achieve the effect of improving the overall bearing capacity, increasing the pile end resistance, and high construction pressure efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

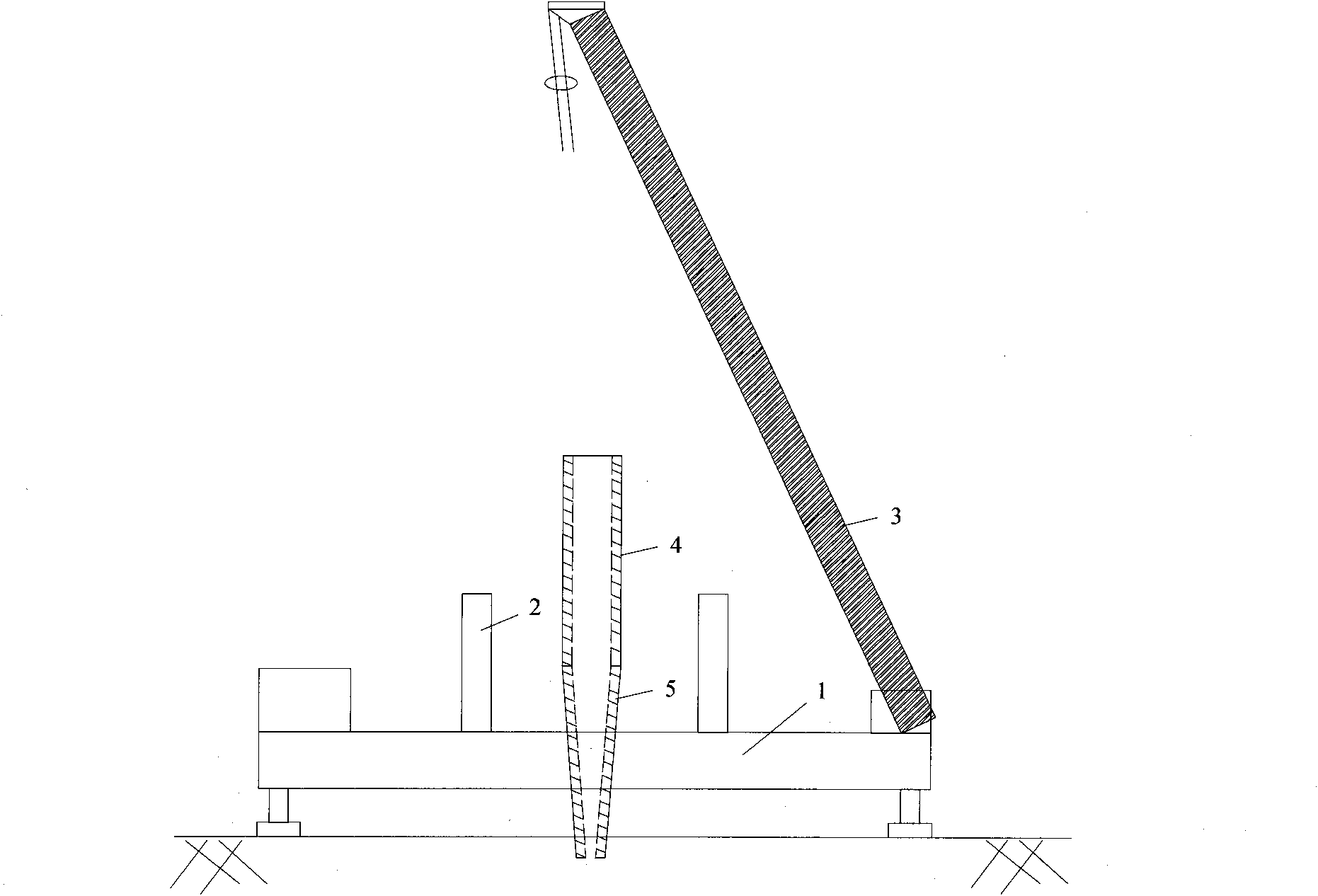

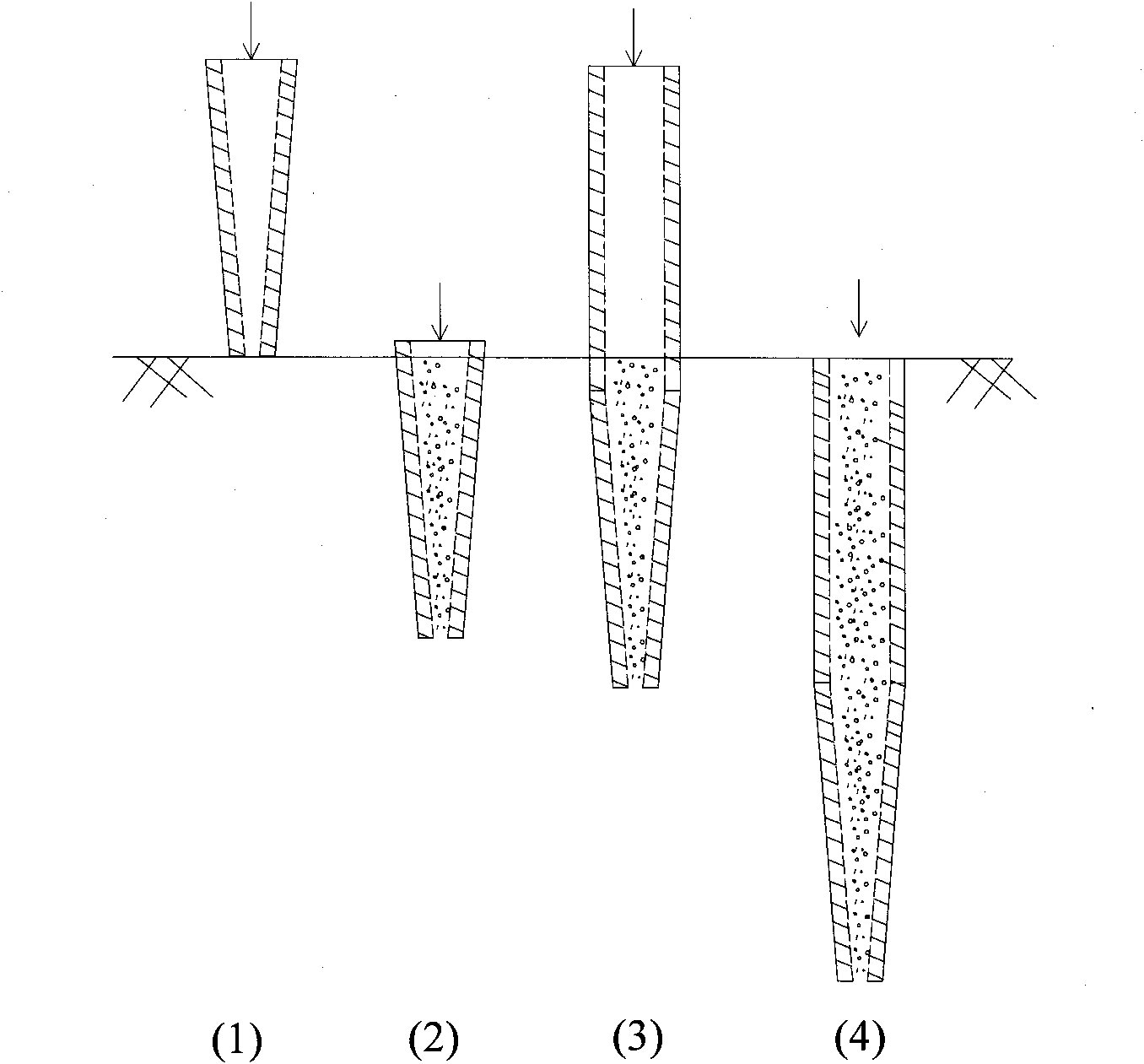

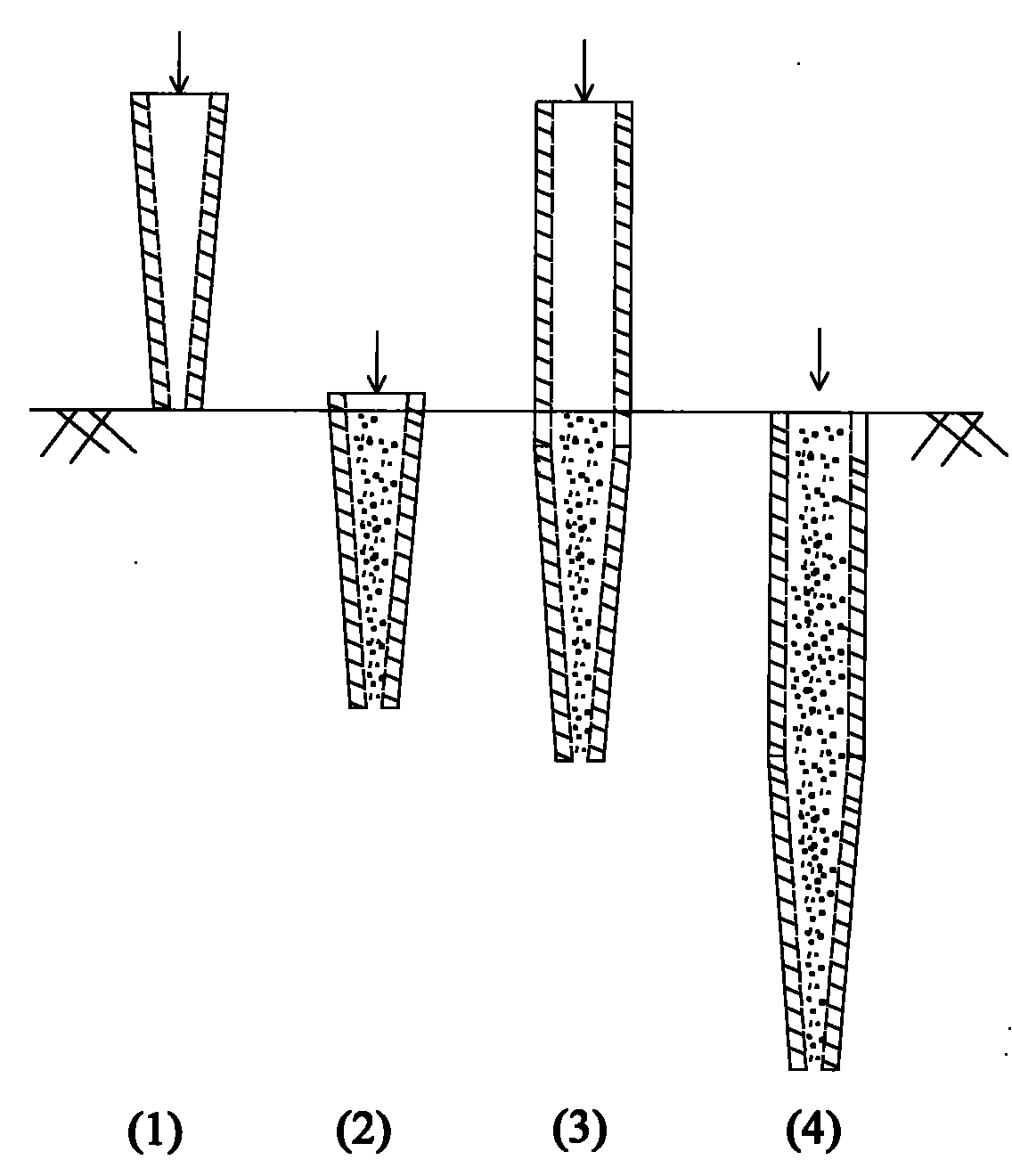

[0010] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings. The protection scope of the present invention is not limited only to the description of this embodiment.

[0011] According to the properties of the soil layer and the design and construction requirements of the pipe pile, the present invention designs the combination form of the prestressed pipe pile and the prestressed wedge pipe pile, so that the pile foundation can achieve the best technical and economic effect; the prestressed pipe joint adopts the pretensioning prestressing process It is made by the centrifugal forming method; the threaded mechanical quick joint method is used to connect the pipe joints; generally, the lower part of the pipe pile combination adopts the prestressed wedge pipe pile pipe joint, and the upper part adopts the prestressed pipe pile pipe joint combination. According to the properties o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com