Steel pipe pile locking notch structure and water-stopping method of steel pipe pile cofferdam

A technology of steel pipe piles and locks, which is used in infrastructure engineering, sheet pile walls, buildings, etc., can solve problems such as difficulty in waterproofing and plugging of locks, and improve the ability of waterproofing and plugging, and the bonding force is improved and increased. The effect of the water path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

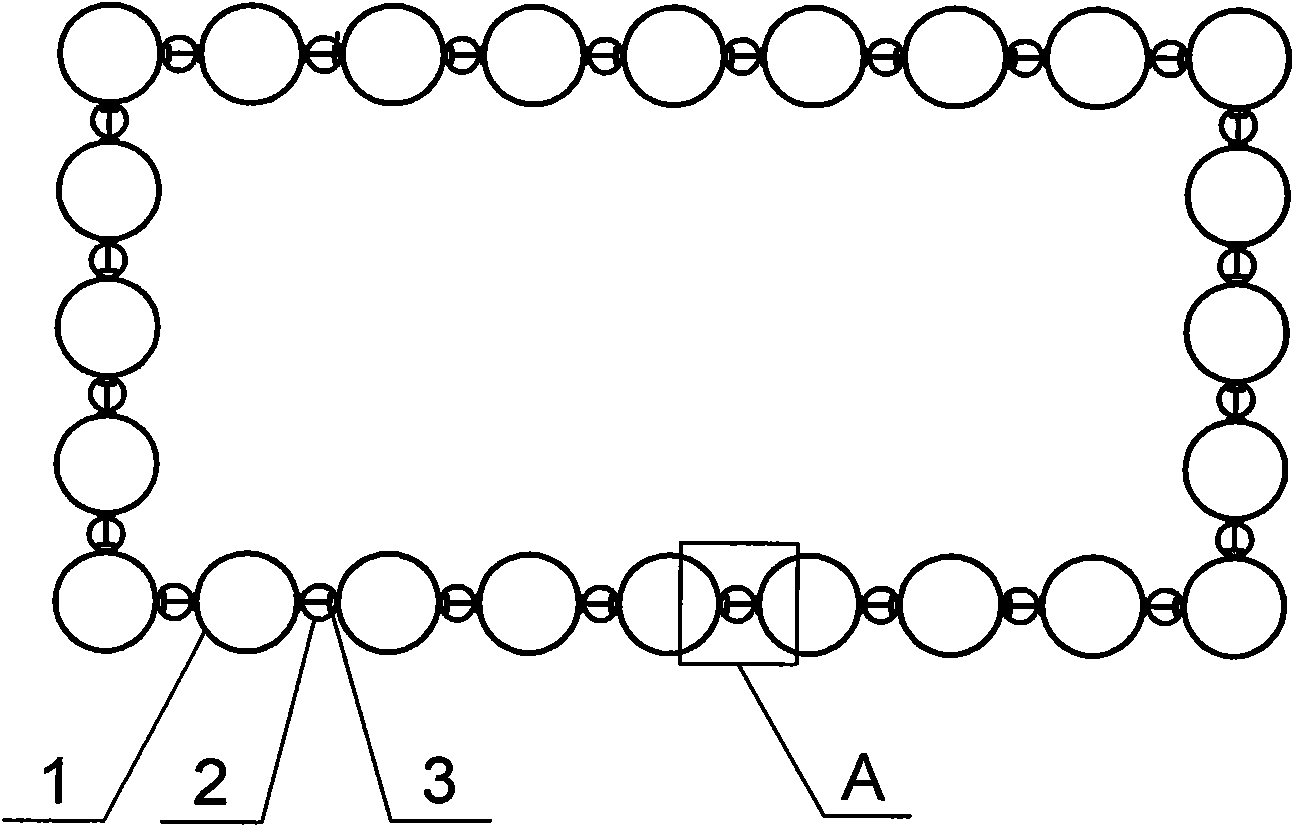

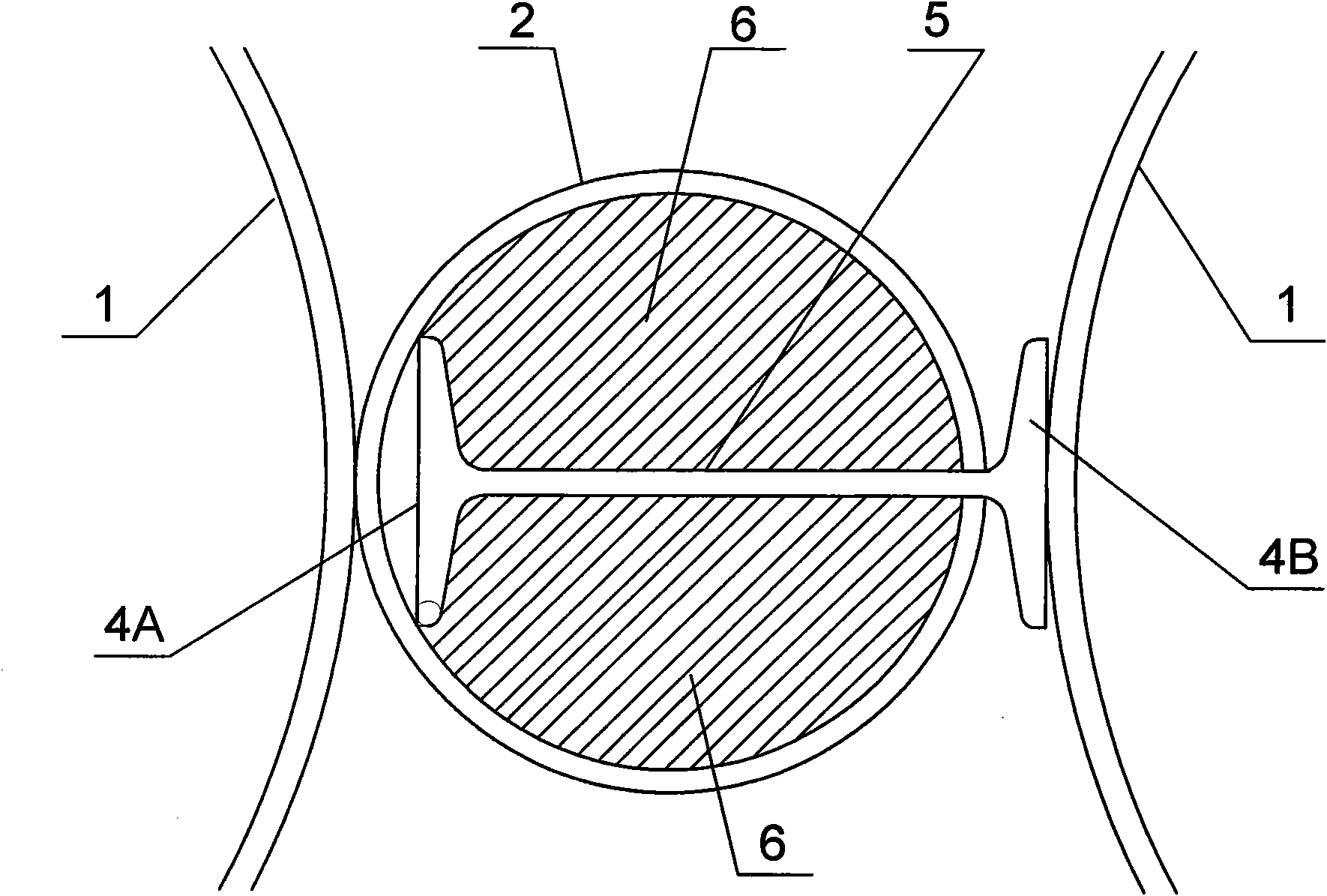

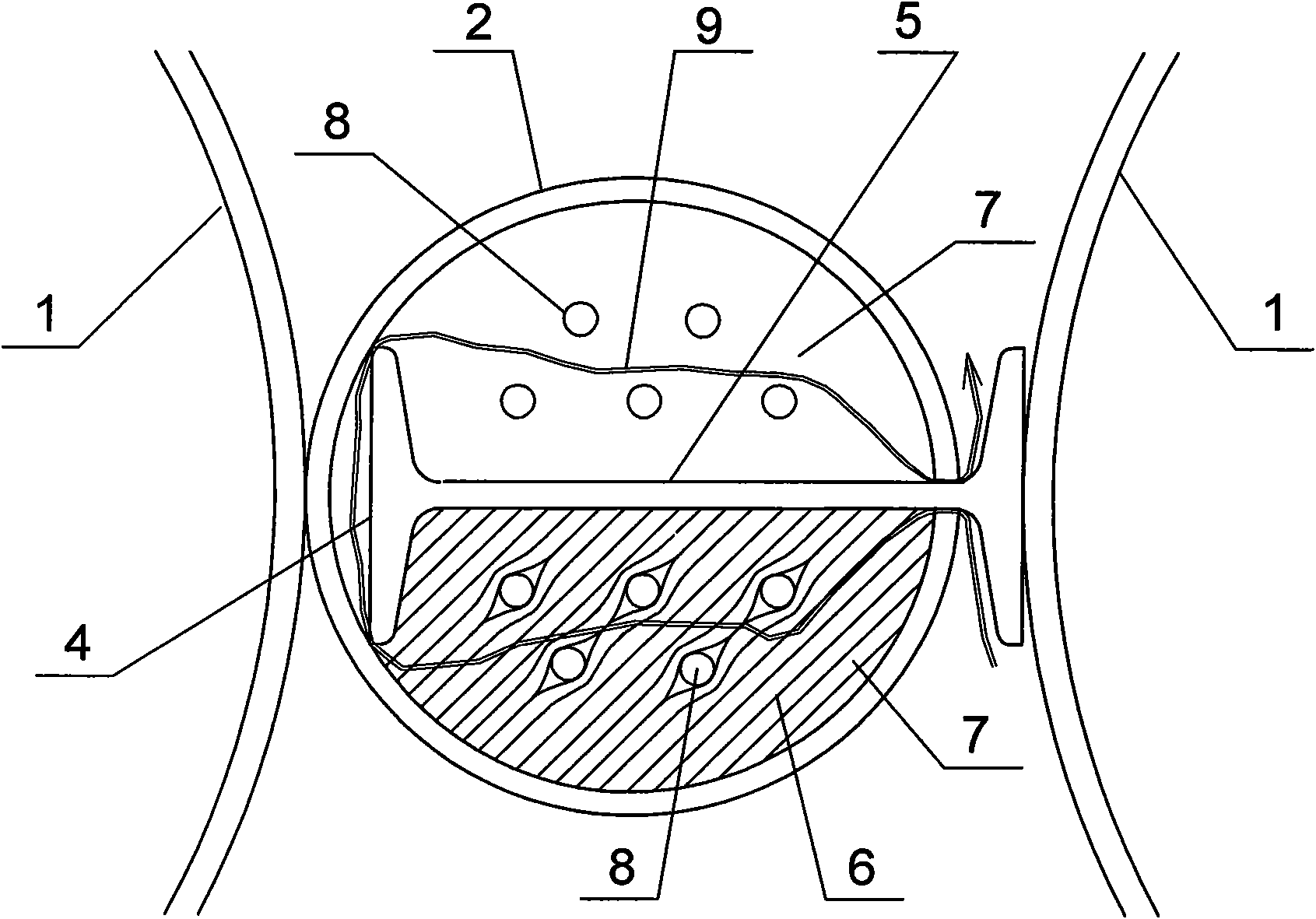

[0020] Depend on figure 1 and figure 2 A lock structure of steel pipe piles is shown, which includes steel pipe piles 1 arranged in rows at intervals and surrounded by a square shape, and locks are arranged between two adjacent steel pipe piles 1, and the locks are composed of female locks and male locks. The male lock is I-shaped steel 3, and the female lock is steel pipe 2 with slits along the axial direction. , the lower two flange plates 4A, 4B, the I-shaped steel web 5 is inserted in the slit, the width of the steel pipe 2 slit is less than the width of the I-steel web 5, and the I-steel web 5 is closely matched with the slit. The upper flange plate 4A is located in the female lock steel pipe 2 and against the inner wall of the female lock steel pipe 2 on the opposite side of the slit, the upper flange plate 4A of the I-beam 3 and part of the web 5 contained in the slit steel pipe 2 To form a water-proof part, the lower flange plate 4B of the I-beam 3 is located outsid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com