Clamping device of injection head of continuous string coiled tubing

A clamping device and tubing technology, applied in the direction of drill pipe, casing, drill pipe, etc., can solve the problems of uneven force on the clamping block, clamping deflection, and weakening of the force on the saddle clamping block, etc., to achieve Improve the effect, strong clamping force, easy to align the effect of the wellhead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

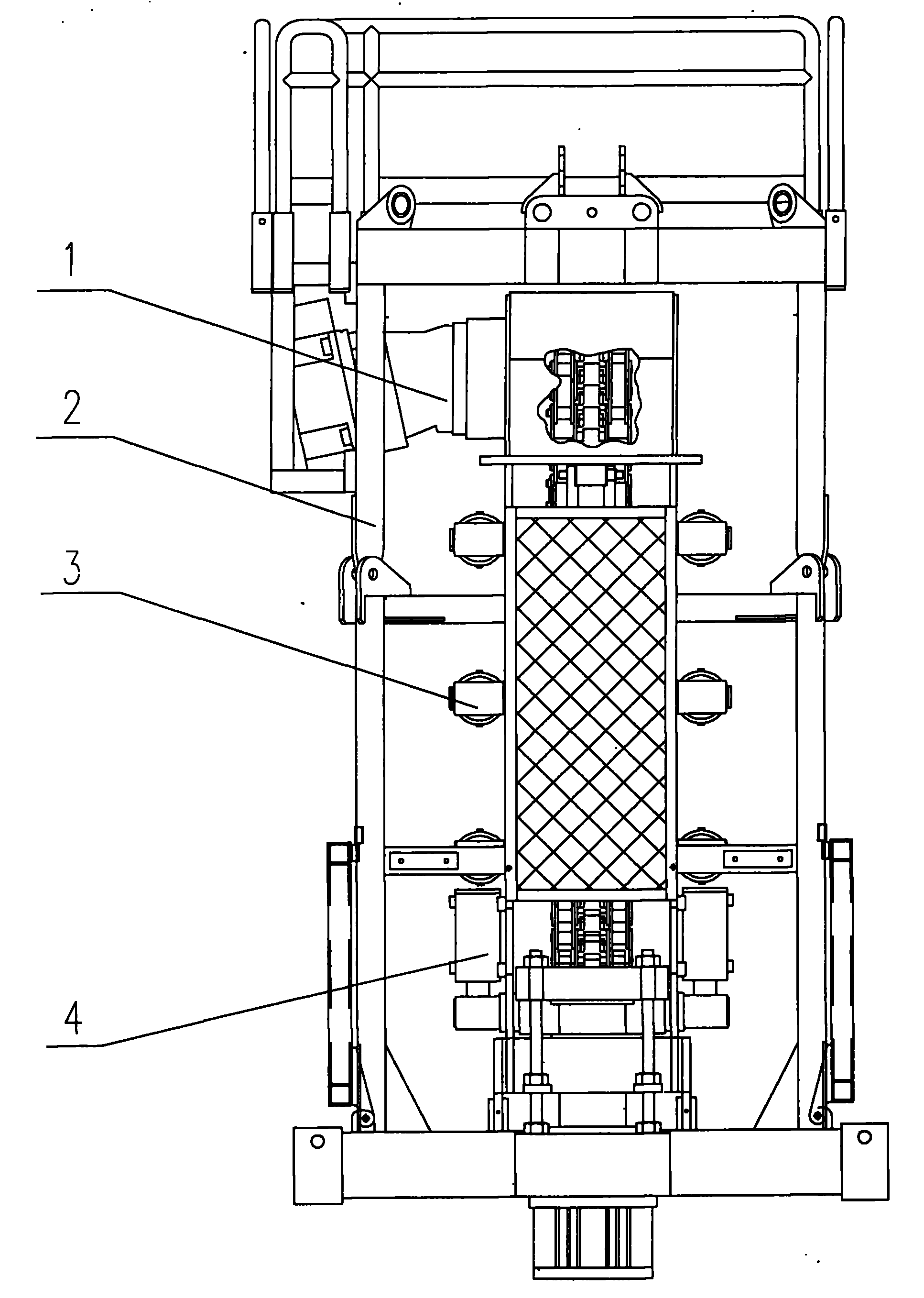

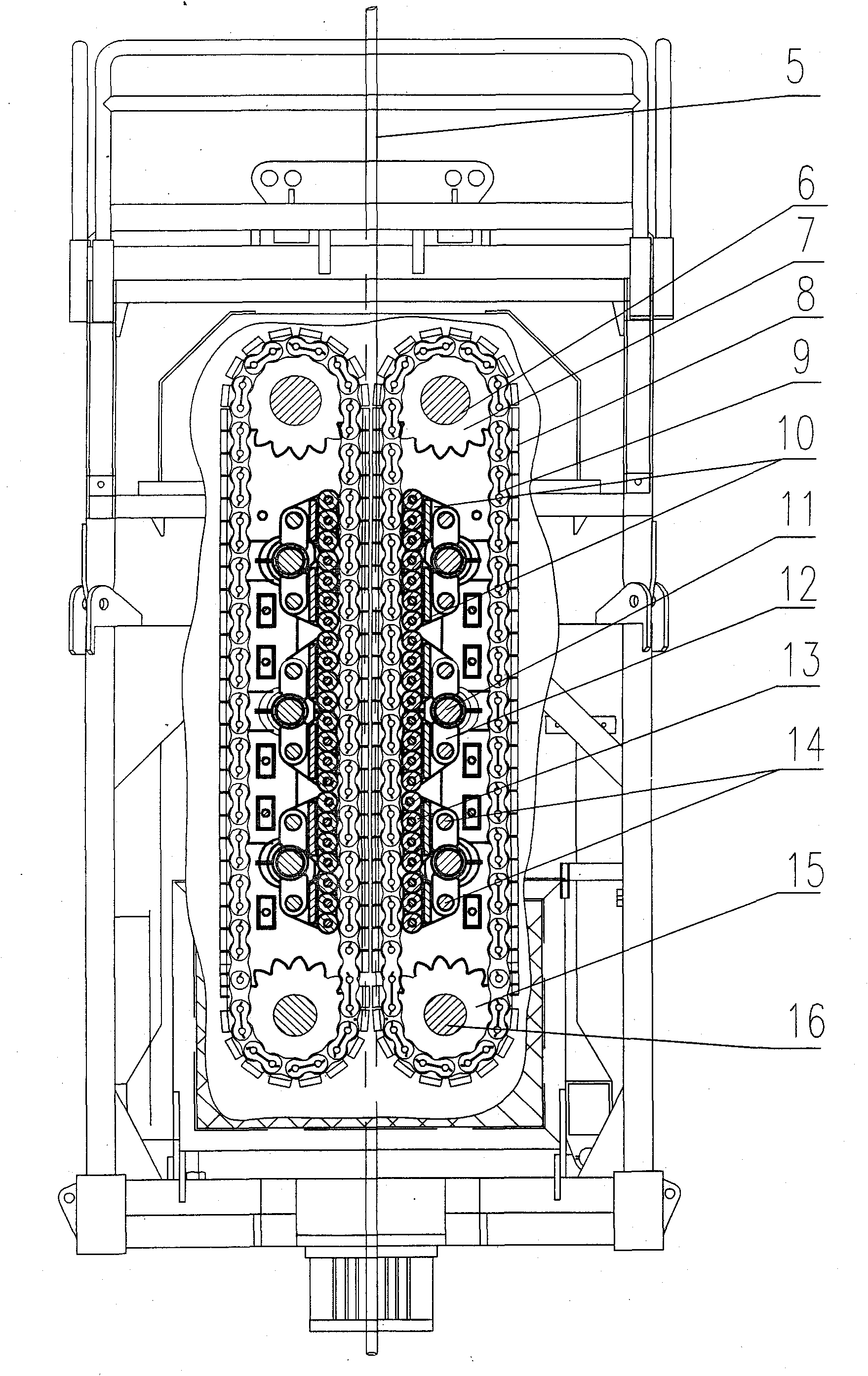

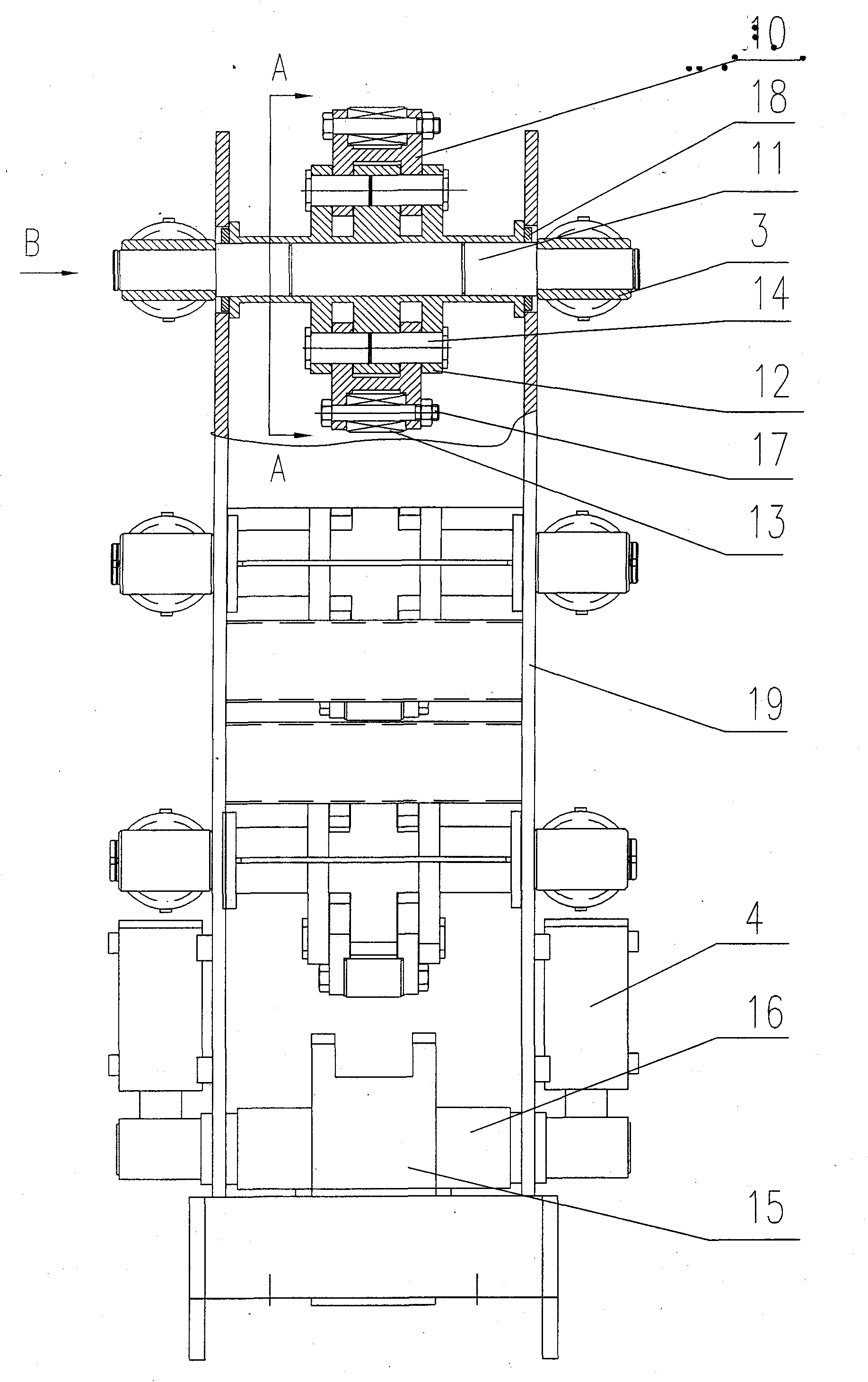

[0017] Attached below Figure 1-5 The specific embodiment of the present invention will be further described.

[0018] see figure 1 , figure 2 and image 3 The coiled tubing clamping device of the injection head is supported by the frame 2 and the frame side plate 19. When the coiled tubing 5 is lowered into the oil well, the hydraulic motor works under the control of the hydraulic system of the equipment. Transmission to the drive shaft 6 in the drive box 1, so as to drive the two drive sprockets 7 mounted on the drive shaft 6 to rotate in opposite directions, and then drive the two pairs of chains 9 to move downward, and the four sets of tension cylinders 4 push the shaft 16 The tensioning sprocket 15 on the top makes the chain 9 tense. At the same time, under the control of the hydraulic system, the three pairs of clamping cylinders 3 are pressurized sequentially from top to bottom, driving the clamping cylinders 3 to shrink, and the clamping cylinders 3 and the shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com