Combustion control method for regenerative-combustion heating furnace

A heat storage combustion and control method technology, which is applied in the direction of combustion method, combustion air/fuel supply, burner, etc., can solve problems such as corrosion, and achieve the effect of preventing combustion exhaust gas from corroding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Next, the combustion control method of the regenerative combustion type heating furnace according to the embodiment of the present invention will be specifically described with reference to the drawings. In addition, the combustion control method of the regenerative combustion type heating furnace concerning this invention is not limited to the method shown in the following embodiment, It can change suitably and implement in the range which does not change the gist of invention.

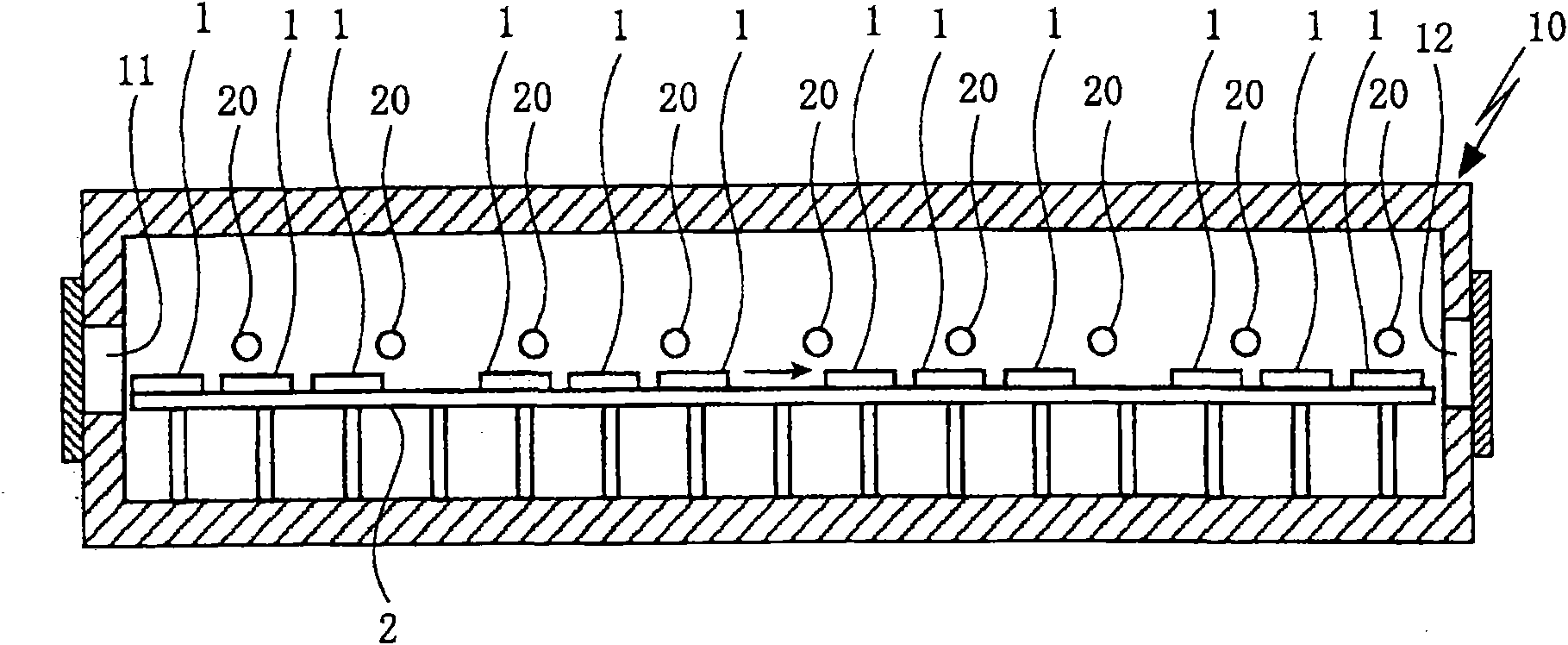

[0045] In this embodiment, if figure 1 As shown, the material to be processed 1 made of steel guided into the heating furnace 10 from the entrance 11 of the heating furnace 10 is transported in the heating furnace 10 by the transport roller 2, and it is heat-treated. The material 1 to be processed is taken out of the heating furnace 10 through the outlet 12 of the heating furnace 10 .

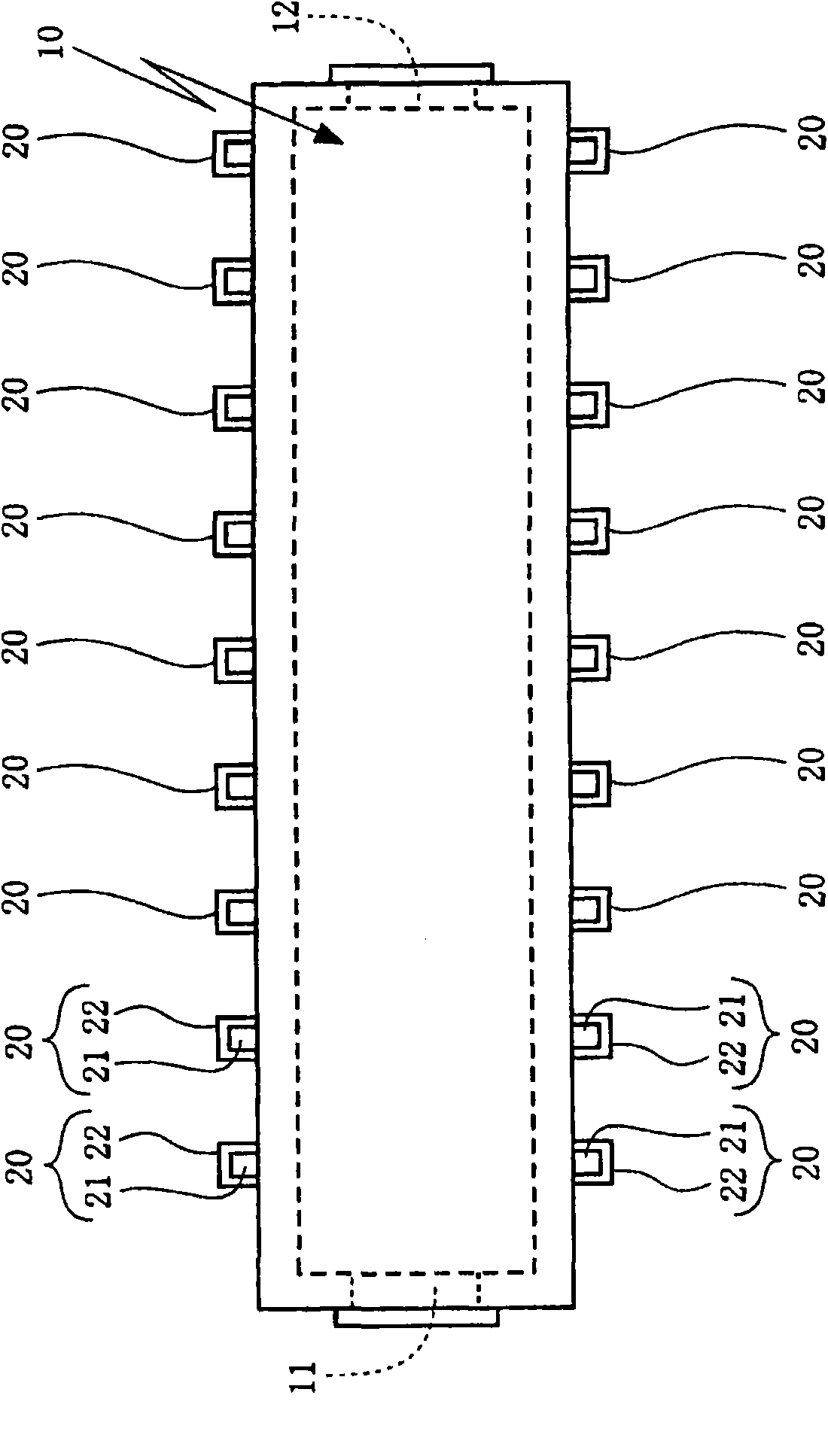

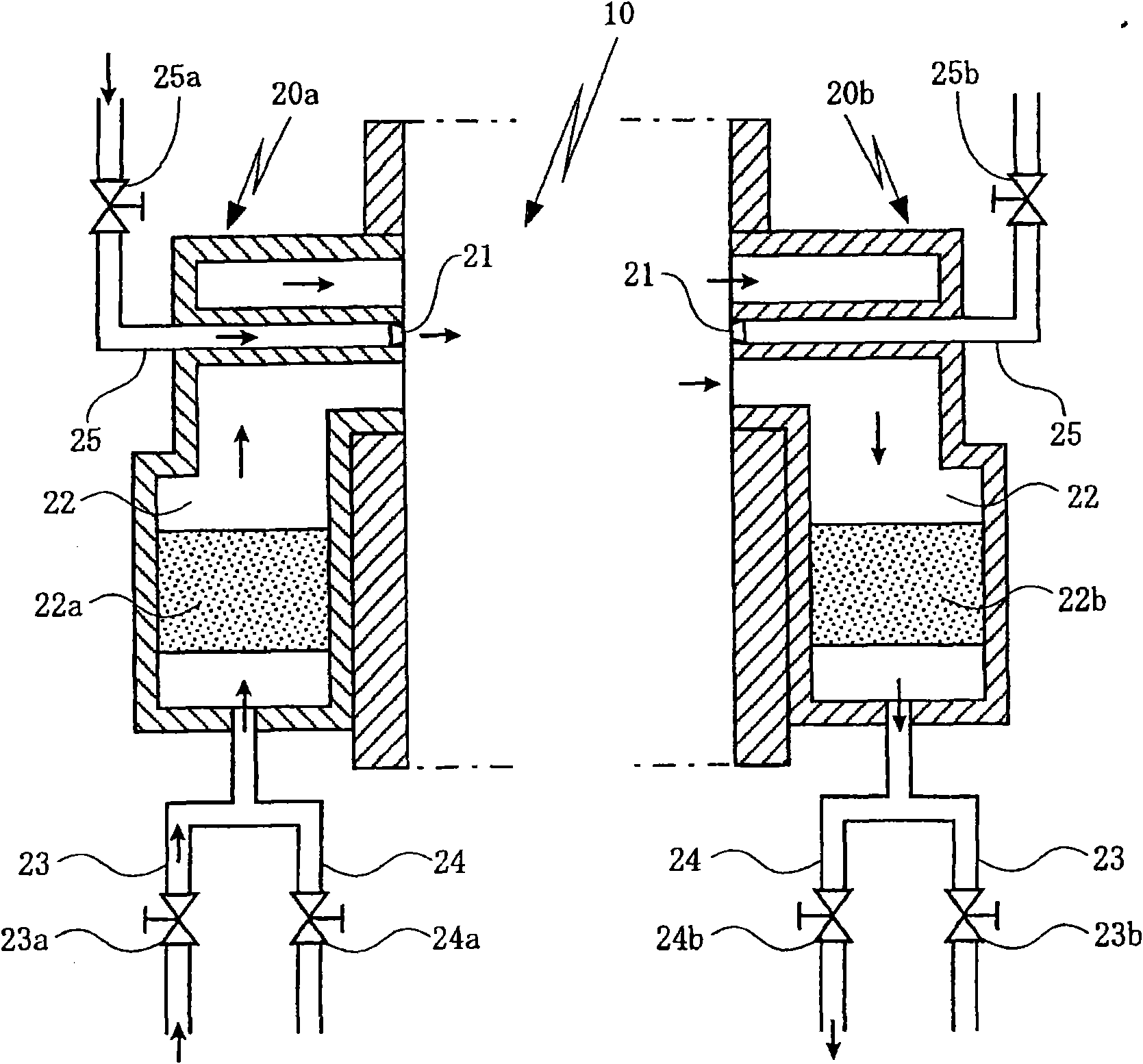

[0046] Furthermore, in this embodiment, if figure 2 As shown, in the above-mentioned heating furnace 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com