Static pressure testing device of solar cell assembly

A technology for solar cells and battery components, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve problems such as difficulty, high operation requirements, scratched glass, etc., to achieve simple and accurate pressure control, accurate pressure control, The effect of wasting water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

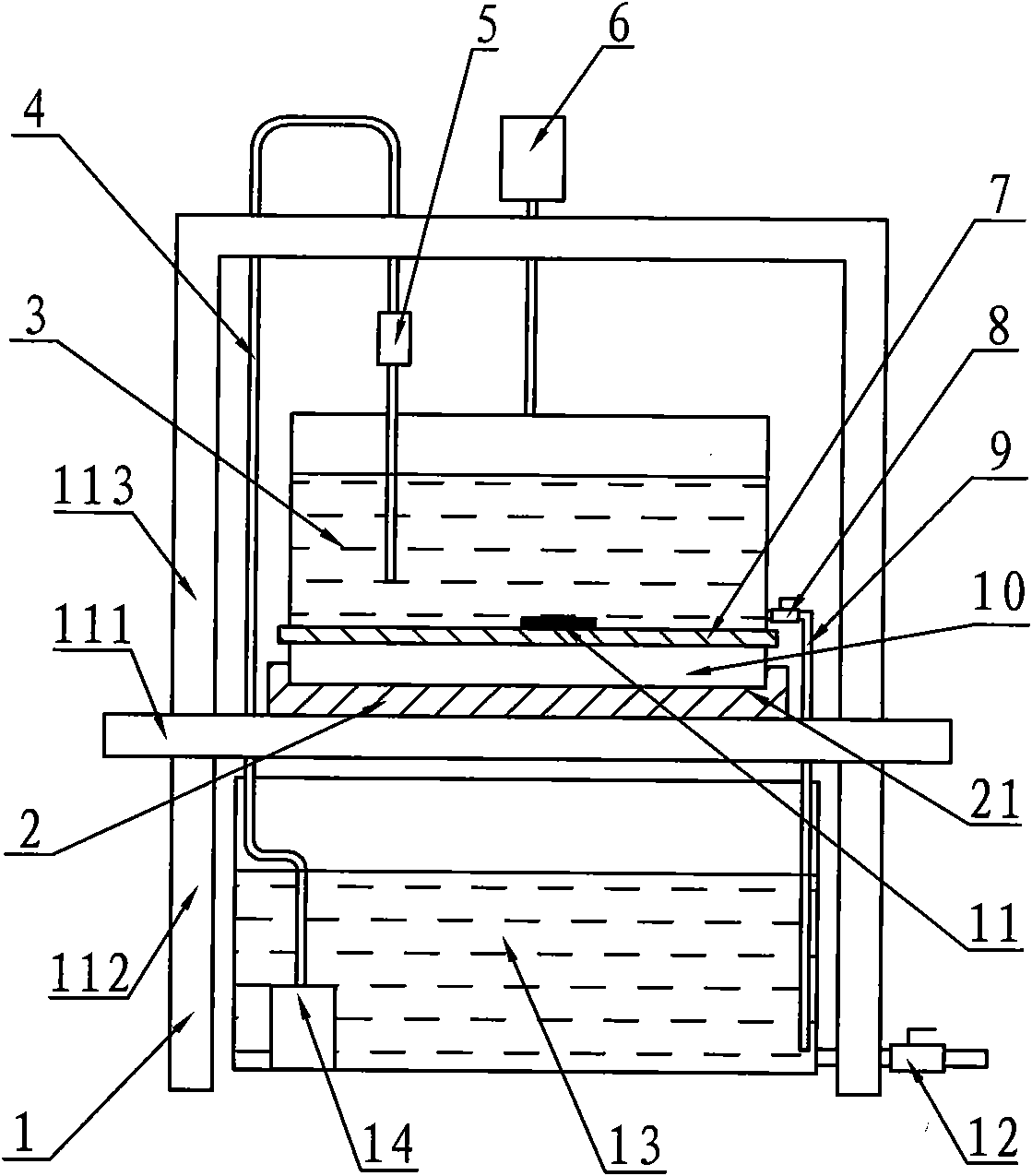

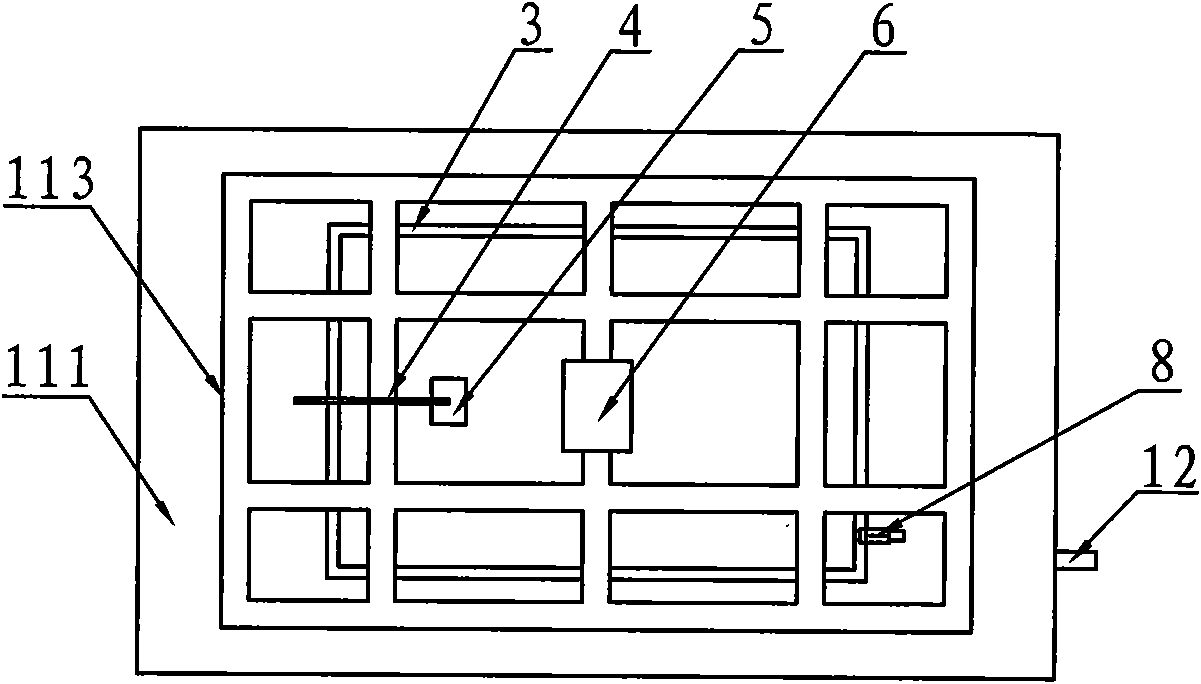

[0012] Such as figure 1 , figure 2 As shown, the solar cell module static pressure test device includes a frame 1, a module support frame 2, a water tank 3, a water inlet pipe 4, a solenoid valve 5, a lifting device 6, a pressure plate 7, a water discharge valve 8, and a drain pipe 9. Battery assembly 10, pressure sensor 11, water supply valve 12, circulating pool 13, self-priming water pump 14, the frame 1 is composed of a horizontal workbench 111, a bench 112 and a gantry frame 113, and the horizontal workbench 111 is placed on the On the platform 112, the gantry frame 113 is placed on the upper end surface of the horizontal workbench 111, and the three are fixedly connected. The support frame 2 is provided with a notch 21 for installing the solar cell assembly 10, the depth of the notch 21 is smaller than the thickness of the cell assembly 10 unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com